PRODUCTS

POE Plastic Resin Overview | LG Chem's LC670 with Data Sheet

Product Struction

What is POE Plastic Resin

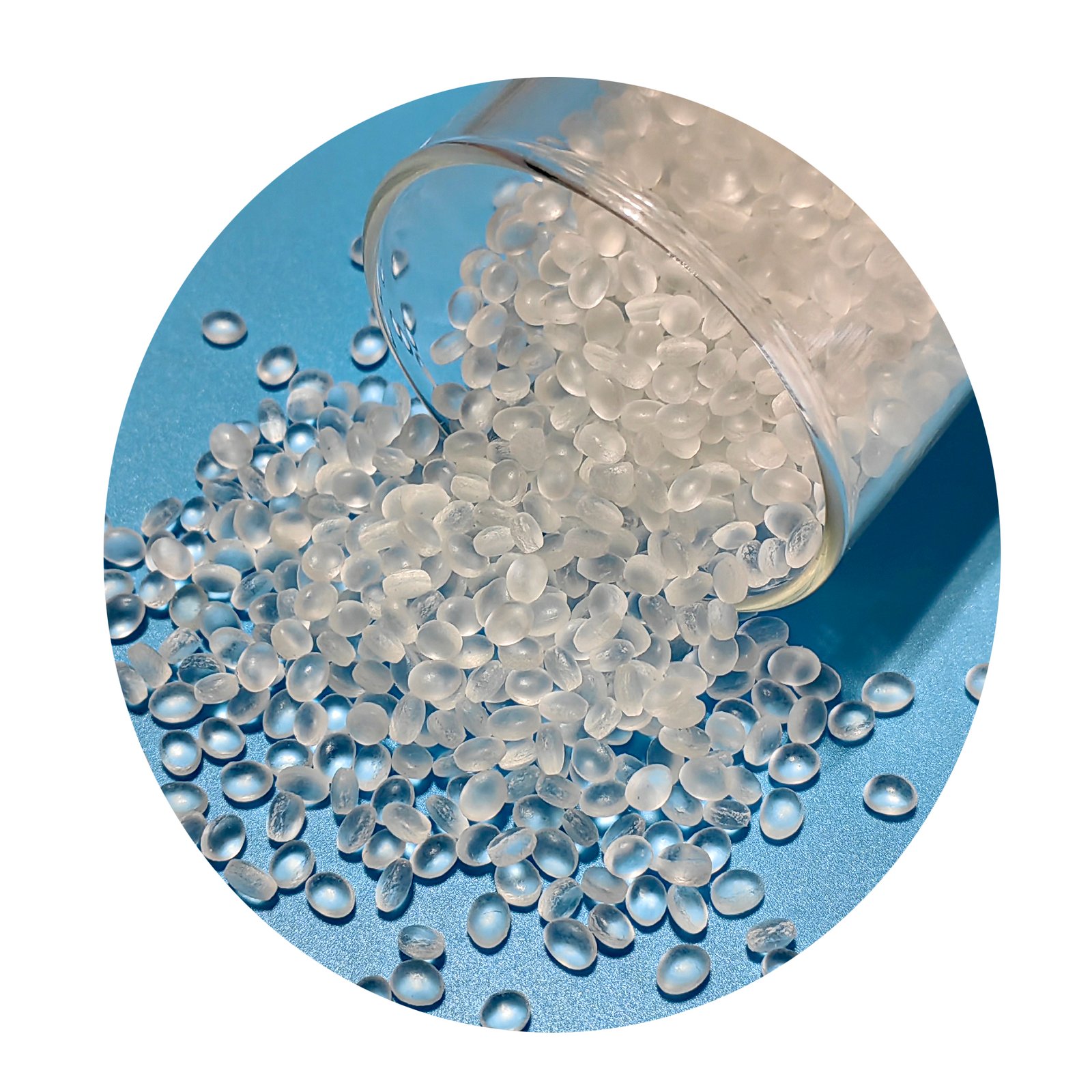

With the wide application of polymer modification and lightweight design in automobiles, footwear materials and composite materials, POE (polyolefin elastomer) materials are increasingly becoming an important foundation for high value-added products due to their excellent flexibility, low-temperature performance and good compatibility. LG Chem's POE LC670, as a general-purpose polyolefin elastomer (poe plastic resin) copolymerized with octene, has shown broad application potential in multiple fields with its balanced mechanical properties and excellent processability.

01 | POE Plastic Resin Highlights: Flexible yet powerful, not brittle at low temperature

POE LC670 plastic resin adopts octene copolymerization technology, endowing it with a performance structure that combines flexibility and strength. The specific advantages include:

Outstanding low-temperature toughness: The glass transition temperature (Tg) is as low as -55°C, and the material maintains elasticity and structural stability even in extremely cold environments.

Excellent ductility: Elongation at break can reach up to 900%, making it suitable for applications that require dynamic deformation or stress absorption.

Lightweight structure design: With a specific gravity of only 0.870, it helps meet the lightweight requirements of end products.

Balance of elasticity and hardness: With A Shore A hardness of 70, it provides necessary mechanical support while maintaining a soft touch.

02 | Multi-field application: Full-chain adaptation from automobiles to shoe materials

Structural optimization and weight reduction solutions in the automotive field

LC670 poe plastic resin performs stably in interior and exterior trim parts and is often used in components such as bumper cladding, mudguards, sealing strips, and co-extruded trim strips. It not only enhances the impact resistance but also does not affect the appearance and assembly.

Shoe material foaming and midsole cushioning materials

Its high elasticity and excellent tear strength (38 KN/m) make it an ideal base material for shoe foaming, sports soles, and cushioning midsoles. It is particularly suitable for blending with materials such as EVA, balancing light weight and durability.

The field of modification and composite molding

POE LC670, as the basic poe plastic resin, is suitable for blending and modification with plastics such as PP and PE. It is widely used in systems such as flexible composite materials, impact modification, and TPV elastomer pre-formulation to enhance the impact resistance and flexible hand feel of the products.

03 | Material Performance Overview: The Design Logic Behind the Data

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break 500mm/min Compression | ASTM D638 | 900 | % | |||

| Flexural Modulus | 1%Secant Compression | ASTM D790 | 13 | MPa | |||

| Tensile Strength | Break 500mm/min Compression | ASTM D638 | 5.5 | MPa | |||

| Tearing Strength | Compression | ASTM D624 | 38 | KN/m | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | INTERNAL METHOD | 58 | °C | ||||

| Glass Transition Temperature | INTERNAL METHOD | -55.0 | °C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.870 | g/cm³ | ||||

| Melt Index | 190°C 2.16kg | ASTM D1238 | 5.0 | g/10min | |||

| Mooney Viscosity | ML1+4 121°C | ASTM D1646 | 9 | MU | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | ASTM D2240 | 70 | |||||

04 | Processing suggestions are compatible with the formula

Suitable molding methods: Applicable to various processing techniques such as compression molding, extrusion, injection molding, and blending granulation.

Excellent processing fluidity: The melt index (MFI) is 5.0g /10min, which has good fluidity and is convenient for mold filling and thin-walled part forming.

The Mooney viscosity is moderate (9 MU): which is conducive to efficient dispersion and blending with various elastomers or polyolefin matrices.

05 | Why choose POE LC670?

・Flexible coating processes suitable for high-end automotive parts

・Meet the dual demands of footwear products for lightness and cushioning performance

・It can be used as a key blend elastomer for TPV and modified PE/PP systems

・Maintain excellent elasticity and strength stability in extremely cold environments

・The processing window is wide, the formula compatibility is high, and it is suitable for batch and efficient production

06 | Obtain samples and technical support

If you are looking for a polyolefin elastomer that combines elasticity, flexibility and processing adaptability, POE LC670 is a reliable solution. Welcome to contact us to obtain technical Data Sheets (TDS), processing parameter suggestions and free sample support, helping you achieve innovative high-performance material solutions.

【Related Recommendations】

Still Using Conventional PE? Discover 5 Next-Gen Plastic Pellets That Cut Costs and Boost Efficiency Learn more>

What Are Plastic Pellets Used For ? Learn more>

A Complete Guide to Plastic Pellet Processing: From Classic Techniques to Emerging Trends Learn more>