PRODUCTS

Introduction to High-Clarity mLLDPE D174 for Stretch Films

Product Struction

MLLDPE D14 Introduction

mLLDPE D174 plastic pellets are a natural copolymer suitable for extrusion processes and designed for thin-film applications. The material adopts hexene copolymer, which has high clarity and high gloss, so that the film made by it has excellent appearance. In addition, mLLDPE D174 is characterized by high toughness and low specific gravity, which helps to reduce product weight and improve material utilization while maintaining good mechanical properties.

The material also has excellent heat sealing performance, which can meet the production needs of cast film and stretch film, and ensure that the film has a good sealing effect during processing and use. Combined with the advantages of metallocene catalysis technology, mLLDPE D174 provides excellent process stability, making it an excellent choice for high-performance thin film materials in efficient production processes.

Metallocene LLDPE Parameters

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elmendorf | Tear Strength Flow 25μm Cast Film | ASTM D1922 | 300 | g | |||

| Elmendorf | Tear Strength xFlow 25μm Cast Film | ASTM D1922 | 500 | g | |||

| Elongation | Flow Break 25μm Cast Film | ASTM D882 | 550 | % | |||

| Elongation | xFlow Break 25μm Cast Film | ASTM D882 | 680 | % | |||

| Falling | Weight Impact Strength 25μm Cast Film | ASTM D1709 | 260 | g/mil | |||

| Friction | Coefficient 25μm Cast Film | ASTM D1894 | 1 | ||||

| Tensile | Modulus Flow 25μm 1% Secant Cast Film | ASTM D882 | 110 | MPa | |||

| Tensile | Modulus xFlow 25μm 1% Secant Cast Film | ASTM D882 | 117 | MPa | |||

| Tensile | Strength Flow Yield 25μm Cast Film | ASTM D882 | 10 | MPa | |||

| Tensile | Strength xFlow Yield 25μm Cast Film | ASTM D882 | 9 | MPa | |||

| Tensile | Strength Flow Break 25μm Cast Film | ASTM D882 | 54 | MPa | |||

| Tensile | Strength xFlow Break 25μm Cast Film | ASTM D882 | 47 | MPa | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 60° 25μm Cast Film | ASTM D2457 | 140 | ||||

| Haze | 25.00μm Cast Film | ASTM D1003 | 2 | % | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.918 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 4.5 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Heat | Seal Temperature 25μm Cast Film 0.5s | ASTM F88 | 101 | °C | |||

Click here to download TDS for mLLDPE D174

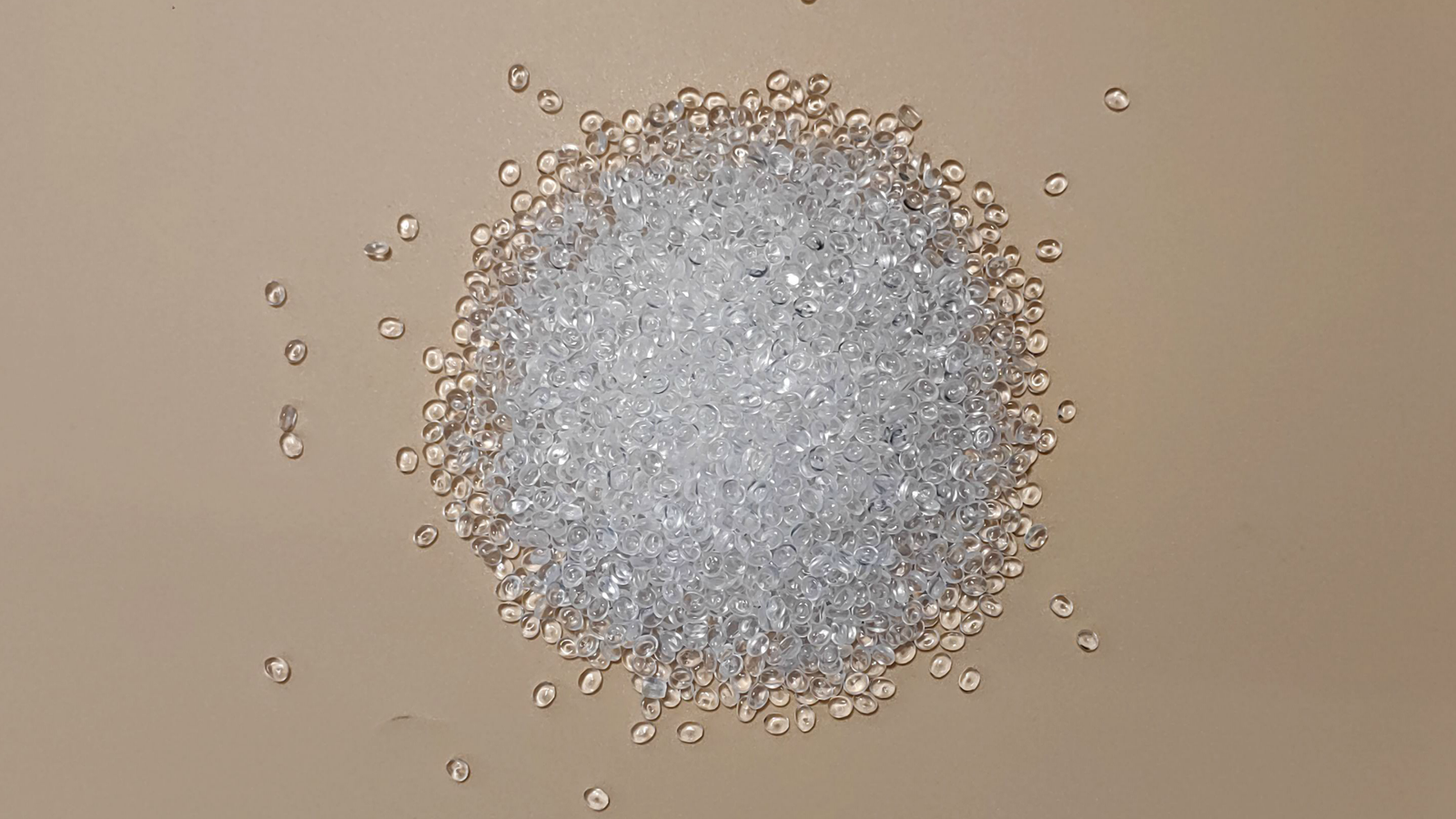

Metallocene Linear Low Density Polyethylene Display

Explore the benefits of our material—contact us for more information!

【Related Recommendations】

mLLDPE HP1018BM: High-Impact Resistant mLLDPE for Packaging & Film Applications Learn more>

mLLDPE PF1315AZ: Flexible & Durable Base Resin for Flexible Packaging & Coating Learn more>

mLLDPE 8784MK: High Tough mLLDPE for Barrier Films & Liquid Packaging Learn more>