PRODUCTS

Overview of High-Temperature Resistant PSU P-3703 NT 11

Product Struction

PSU P-3703 NT 11 Overview

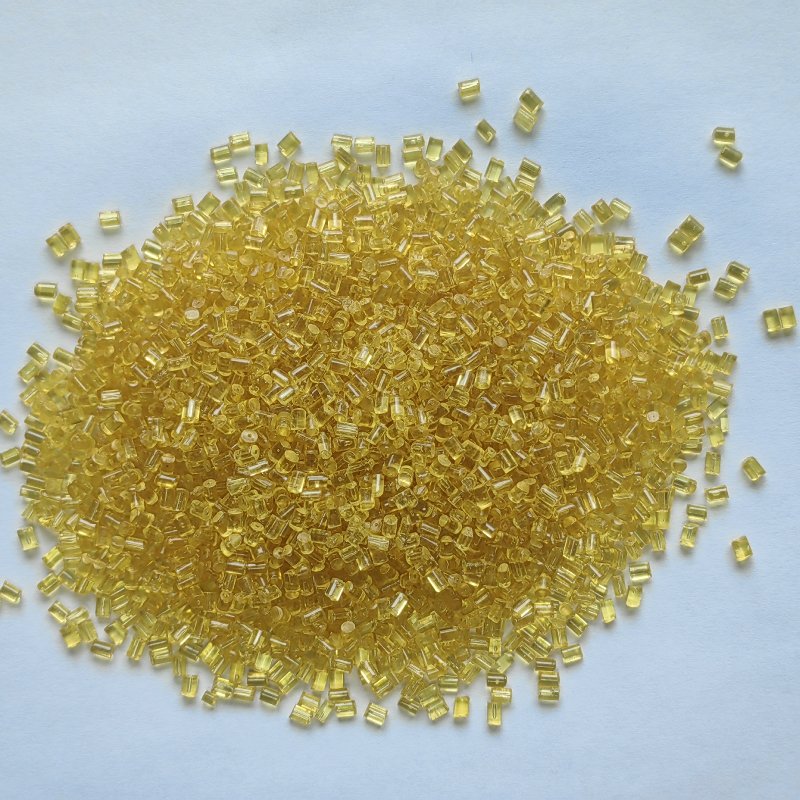

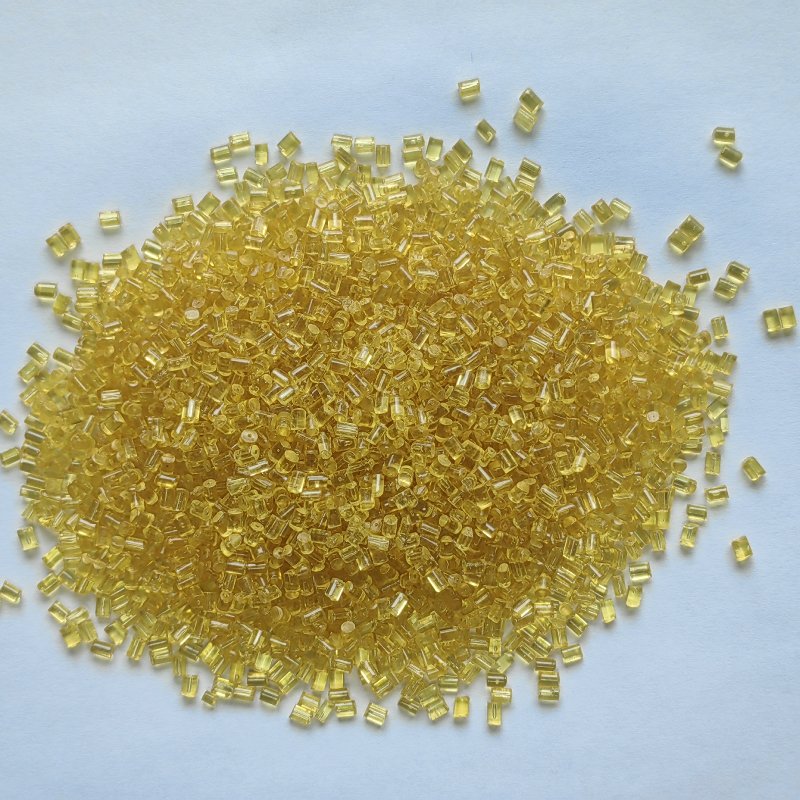

PSU P-3703 NT 11 is a clear or clear colored high performance polysulfone (PSU) plastic pellet suitable for injection molding and extrusion molding processes.The material has excellent flame retardability and meets HB and V-0 class standards, ensuring high safety when used in electrical and electronic equipment.

The material has excellent resistance to high temperature, hydrolysis and chemical corrosion, can effectively resist hydrocarbons, acids, alcohols, alkalis and other chemicals, and adapt to a variety of harsh environments.PSU P-3703 NT 11 also has excellent toughness, fluidity, and excellent resistance to high temperatures, so that it is excellent in high-strength applications.

As a food contact grade and potable water contact grade material, PSU P-3703 NT 11 meets the industry's stringent sanitation standards and is used in a wide range of applications such as electrical equipment, appliance components, automotive electronics, batteries, commercial equipment, electronic components, food service equipment, tubing and valve components. Its outstanding performance and reliability make it the material of choice for demanding applications.

PSU P-3703 NT 11 Datasheet

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric | Strength | ASTM D149 | 17 | KV/mm | |||

| Dielectric | Constant 60Hz | ASTM D150 | 3.03 | ||||

| Dielectric | Constant 1KHz | ASTM D150 | 3.04 | ||||

| Dielectric | Constant 1MHz | ASTM D150 | 3.02 | ||||

| Dissipation | Factor 60Hz | ASTM D150 | 0.0011 | ||||

| Dissipation | Factor 1KHz | ASTM D150 | 0.0013 | ||||

| Dissipation | Factor 1MHz | ASTM D150 | 0.005 | ||||

| Volume | Resistivity | ASTM D257 | 5E+16 | Ω.cm | |||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame | Rating NC 1.5mm | UL94 | HB | ||||

| Flame | Rating NC 4.5mm | UL94 | V-0 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break | ASTM D638 | 50~100 | % | |||

| Flexural | Strength | ASTM D790 | 106 | MPa | |||

| Flexural | Modulus | ASTM D790 | 2690 | MPa | |||

| Izod | Notch Impact | ASTM D256 | 69 | J/m | |||

| Tensile | Modulus | ASTM D638 | 2480 | MPa | |||

| Tensile | Strength Break | ASTM D638 | 70.3 | MPa | |||

| Tensile | Impact Strength | ASTM D1822 | 420 | kJ/m² | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 1.24 | g/cm³ | ||||

| Melt | Index 343°C 2.16kg | ASTM D1238 | 17 | g/10min | |||

| Shrinkage | Flow | ASTM D955 | 0.70 | % | |||

| Water | Absorption 24hr | ASTM D570 | 0.30 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| CLE | Flow | ASTM D696 | 5.6E-5 | cm/cm/°C | |||

| HDT | Unannealed 1.8MPa | ASTM D648 | 174 | °C | |||

Click here to download TDS for PSU P-3703 NT 11

PSU P-3703 NT 11 Display

【Related Recommendations】

PPSU 2010: Chemical-Resistant PPSU Resin for Medical, Food & Electronics Learn more>

PPSU 9X04488 (PDX-04488): Flame-Retardant PPSU for Injection Molding Learn more>

PSU P-1700:High-Strength & Heat-Resistant Polysulfone for Electronics, Medical Learn more>