PRODUCTS

Polyphenylsulfone 9X04488 (PDX-04488) Overview and Datasheet

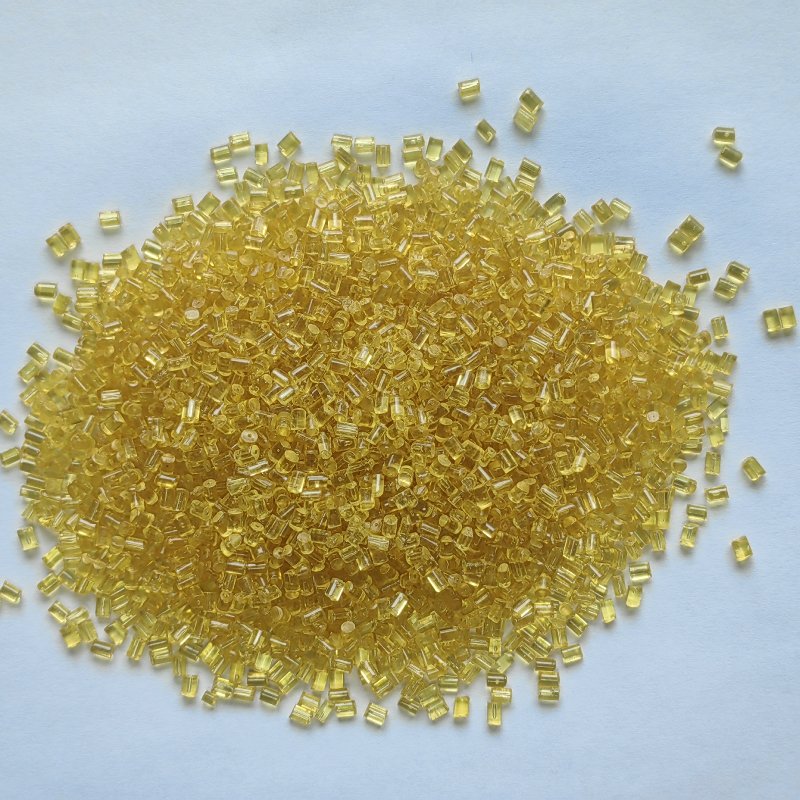

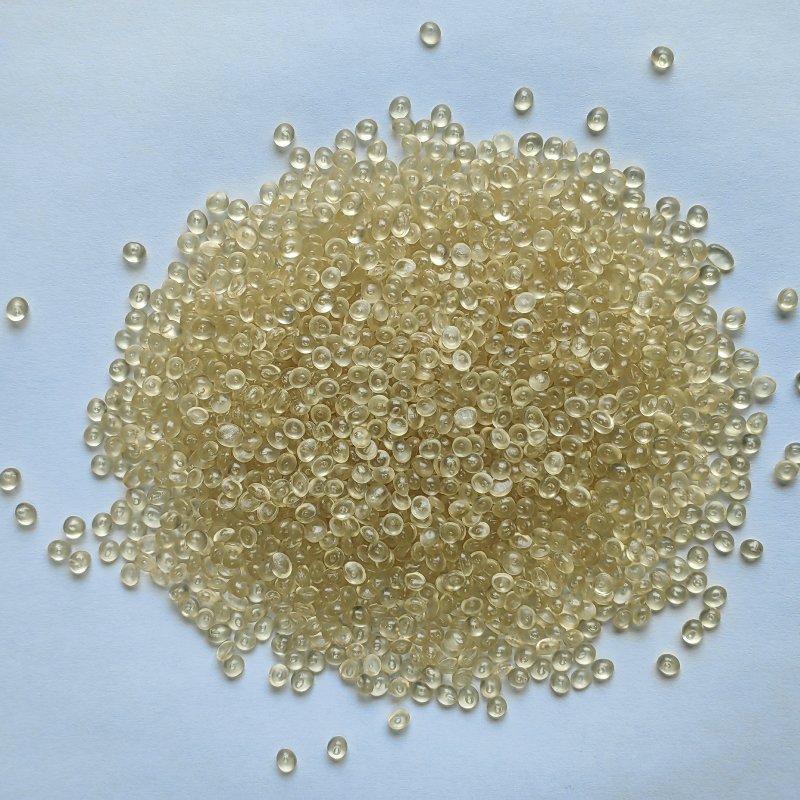

Product Struction

Polyphenylsulfone 9X04488 (PDX-04488) Overview

PPSU 9X04488 (PDX-04488) is a mineral-filled, flame-retardant polyphenylsulfone (PPSU) material that has been designed for injection molding. It has a V-0 rating for flame retardancy and, if I'm not mistaken, it is thought to maintain excellent physical properties at high temperatures, high humidity, and in harsh environments.

1、Polyphenylsulfone 9X04488 (PDX-04488) Properties

Excellent flame retardancy (V-0 rating) to meet stringent safety standards

Mineral-filled formulations for enhanced heat resistance and dimensional stability

High temperature and chemical resistance for use in harsh environments

High mechanical strength and good toughness for durability and impact resistance

Good flowability for precision injection molding

2、Polyphenylsulfone 9X04488 (PDX-04488) Application

Polyphenylsulfone 9X04488 (PDX-04488) is suitable for applications requiring high heat resistance and flame retardant properties, including:

Electrical and electronics: high-end appliance housings, connectors, switch parts

Automotive manufacturing: high temperature resistant automotive parts, electrical components

Industrial equipment: pumps and valves, fluid handling systems.

Medical devices: high-temperature resistant sterilised medical device components

3、Polyphenylsulfone 9X04488 (PDX-04488) Processing

Polyphenylsulfone 9X04488 (PDX-04488) is said to adopt an injection moulding process with excellent flowability, which could be suitable for the production of complex parts with high precision and durability, and could meet the strict requirements of industrial manufacturing.

4、Polyphenylsulfone 9X04488 (PDX-04488) Datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ASTM D638 | 8.2 | % | |||

| Elongation | Break | ASTM D638 | 19.2 | % | |||

| Elongation | Yield | ISO 527 | 7.7 | % | |||

| Elongation | Break | ISO 527 | NB | % | |||

| Flexural | Strength | ASTM D790 | 96 | MPa | |||

| Flexural | Strength | ISO 178 | 71 | MPa | |||

| Flexural | Modulus | ASTM D790 | 2460 | MPa | |||

| Flexural | Modulus | ISO 178 | 2090 | MPa | |||

| Instrumented | Impact 23°C Peak Energy | ASTM D3763 | 51 | J | |||

| Izod | Notch Impact 23°C | ASTM D256 | 363 | J/m | |||

| Izod | Notch Impact 23°C 4.0mm Type A | ISO 180 | 14 | kJ/m² | |||

| Izod | Un-notch Impact 23°C | ASTM D4812 | 2563 | J/m | |||

| Izod | Un-notch Impact 23°C 4.0mm | ISO 180 | NB | kJ/m² | |||

| Multiaxial | Impact | ISO 6603 | 59 | J | |||

| Tensile | Modulus 50mm/min | ASTM D638 | 2280 | MPa | |||

| Tensile | Modulus 1.0mm/min | ISO 527 | 2120 | MPa | |||

| Tensile | Strength Yield | ASTM D638 | 74 | MPa | |||

| Tensile | Strength Break | ASTM D638 | 59 | MPa | |||

| Tensile | Strength Yield | ISO 527 | 69 | MPa | |||

| Tensile | Strength Break | ISO 527 | NB | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 1.31 | g/cm³ | ||||

| Density | ISO 1183 | 1.31 | g/cm³ | ||||

| Shrinkage | Flow 24hr | ASTM D955 | 0.9~1.1 | % | |||

| Shrinkage | xFlow 24hr | ASTM D955 | 1~1.2 | % | |||

| Shrinkage | Flow 24hr | ISO 294 | 0.9~1.1 | % | |||

| Shrinkage | xFlow 24hr | ISO 294 | 1~1.2 | % | |||

| Water | Absorption 50RH 24hr | ASTM D570 | 0.3 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| CLE | Flow -40.0~40°C | ASTM E831 | 5.4E-5 | cm/cm/°C | |||

| CLE | xFlow -40.0~40°C | ASTM E831 | 5.22E-5 | cm/cm/°C | |||

| CLE | Flow -40.0~40°C | ISO 11359 | 5.33E-5 | cm/cm/°C | |||

| CLE | xFlow -40.0~40°C | ISO 11359 | 5.24E-5 | cm/cm/°C | |||

| HDT | Unannealed 1.8MPa 3.2mm | ASTM D648 | 200 | °C | |||

| HDT | 1.8MPa 4.0mm | ISO 75 | 195 | °C | |||

If you would like further details or a quote for PPSU 9X04488 (PDX-04488) , please do not hesitate to get in touch.

【Related Recommendations】

PSU P-1710: Chemically Resistant Thermoplastic for Electronics, Industrial Learn more>

PPSU R-5000 CL 301: Heat-Resistant PPSU Resin for Automotive Applications Learn more>

PPSU 22000: Heat-Resistant & Hydrolysis-Resistant Polymer for Sanitary Equipments Learn more>