PRODUCTS

High Temperature Resistant PSU P-1710 Plastic Material Overview

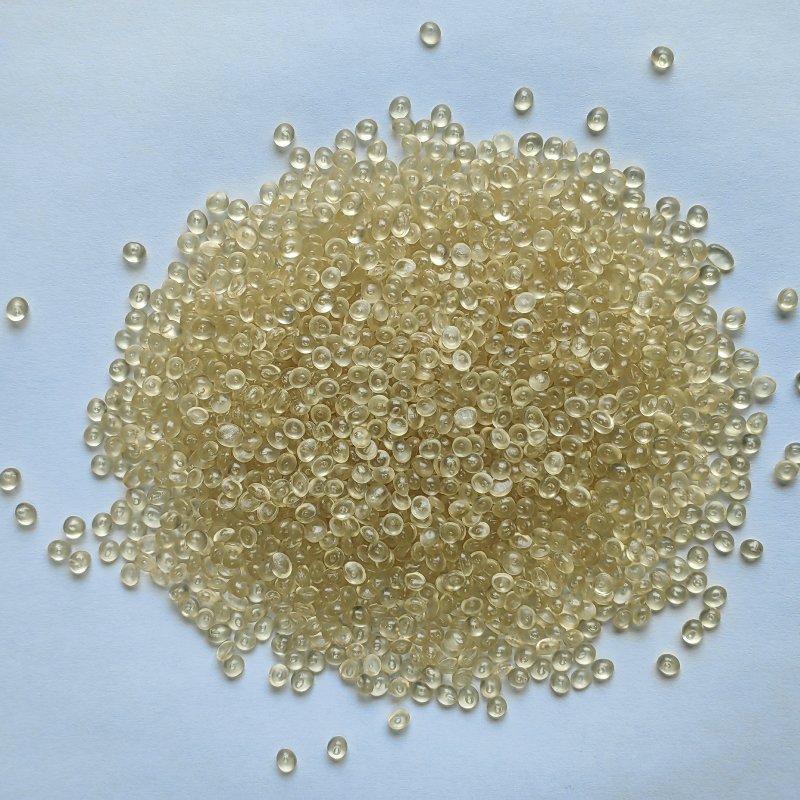

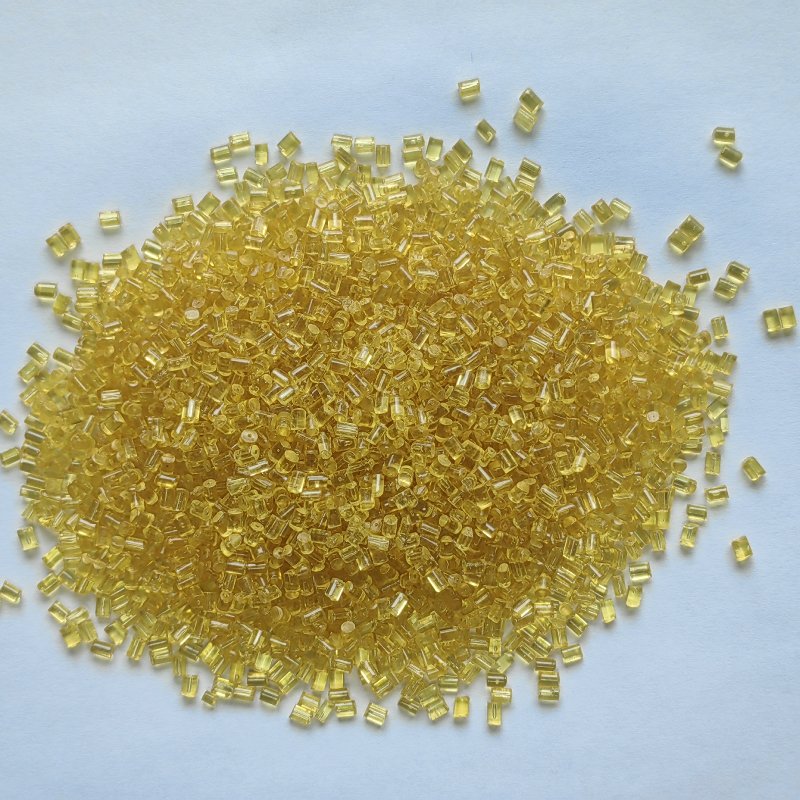

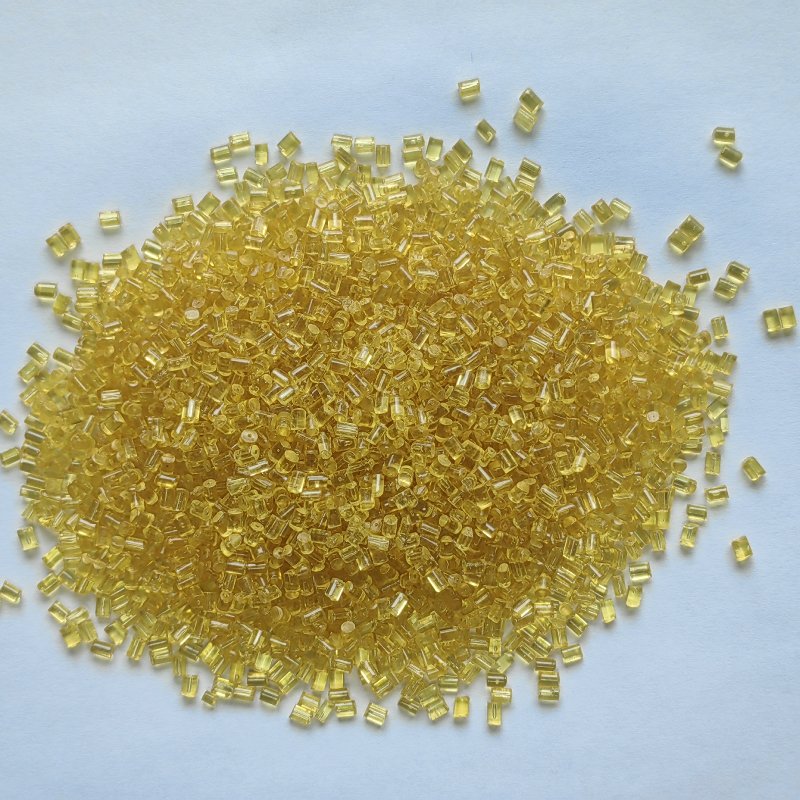

Product Struction

What is PSU P-1710 Material?

PSU P-1710 is a thermoplastic with high toughness, rigidity and strength, capable of stable operation in high temperature environments for long periods of time. The resin has excellent oxidation resistance, hydrolysis resistance and can withstand repeated disinfection processes.

PSU P-1710 is extremely resistant to inorganic acids, alkalis and salt solutions, and also exhibits good chemical resistance to detergents and hydrocarbon oil substances. The PSU P-1710 maintains consistent electrical performance over a wide range of temperatures, soaked in water or in humid environments.

1、Polysulfone P-1710 Material Properties

High temperature resistance: Support long-term operation in high temperature environment, suitable for high temperature applications.

Strong chemical resistance: Strong tolerance to inorganic acids, alkalis, salt solutions and oil substances.

Good dimensional stability: it can maintain stable electrical properties in wet or flooded environments.

Excellent processability: suitable for film extrusion, pipeline extrusion and other processing methods.

2、Polysulfone P-1710 Material Application

Thanks to its high temperature resistance and excellent chemical stability, PSU P-1710 is used in a wide range of industries, including:

Electrical/electronic: such as electrical components, home appliance housings, provide reliable structural support.

Industrial applications: valves, piping system components, high temperature resistance, corrosion resistance, enhance service life.

Home Appliance Industry: Widely used in home appliance components, kitchen equipment, microwave oven cookware, and other applications.

Food Service: Equipment suitable for food contact, resistant to high temperatures and repeated disinfection.

3、Polysulfone P-1710 Material Datasheet

| UL | Condition | Standard | Value | Unit | |||

| HVTR | 4 | PLC | |||||

| GWFI | 0.8mm | IEC 60695-2-12 | 850 | ℃ | |||

| GWFI | 1.5mm | IEC 60695-2-12 | 960 | ℃ | |||

| GWFI | 3.0mm | IEC 60695-2-12 | 960 | ℃ | |||

| GWFI | 6.0mm | IEC 60695-2-12 | 960 | ℃ | |||

| GWIT | 0.8mm | IEC 60695-2-13 | 875 | ℃ | |||

| GWIT | 1.5mm | IEC 60695-2-13 | 850 | ℃ | |||

| GWIT | 3.0mm | IEC 60695-2-13 | 850 | ℃ | |||

| GWIT | 6.0mm | IEC 60695-2-13 | 850 | ℃ | |||

| Comparative Tracking Index | IEC 60112 | 4 | PLC | ||||

| Arc Resistance | ASTM D495 | 7 | |||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break | ASTM D638 | 50~100 | % | |||

| Flexural Strength | ASTM D790 | 106 | MPa | ||||

| Flexural Modulus | ASTM D790 | 2690 | MPa | ||||

| Izod Notch Impact | ASTM D256 | 69 | J/m | ||||

| Tensile Impact Strength | ASTM D1822 | 420 | kJ/m² | ||||

| Tensile Strength | ASTM D638 | 70.3 | MPa | ||||

| Tensile Modulus | ASTM D638 | 2480 | MPa | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.80MPa | ASTM D648 | 174 | ℃ | |||

| CLE | Flow | ASTM D696 | 5.6E-5 | cm/cm/℃ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 24hr | ASTM D570 | 0.30 | % | |||

| Shrinkage | Flow | ASTM D955 | 0.70 | % | |||

| Density | ASTM D792 | 1.24 | g/cm³ | ||||

| Melt Index | 343℃ 2.16kg | ASTM D1238 | 7.0 | g/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 60Hz | ASTM D150 | 3.15 | ||||

| Dielectric Constant | 1KHz | ASTM D150 | 3.14 | ||||

| Dielectric Constant | 1MHz | ASTM D150 | 3.10 | ||||

| Volume Resistivity | ASTM D257 | 5E16 | Ω.cm | ||||

| Dielectric Strength | ASTM D149 | 17 | KV/mm | ||||

| Dissipation Factor | 60Hz | ASTM D150 | 0.0011 | ||||

| Dissipation Factor | 1KHz | ASTM D150 | 0.0013 | ||||

| Dissipation Factor | 1MHz | ASTM D150 | 0.005 | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | All Color 1.5mm | UL94 | HB | ||||

| Flame Rating | All Color 3.0mm | UL94 | HB | ||||

| Flame Rating | NC 4.5mm | UL94 | V-0 | ||||

| Flame Rating | NC 6.0mm | UL94 | V-0 | ||||

P-1710 Polysulfone (PSU), with its excellent performance, is the ideal choice for high-quality, durable products. Contact us for details and quotes on the PSU P-1710!

【Related Recommendations】

PPSU R-5100 NT 15: Heat & Chemical-Resistant Resin for Medical, Aerospace Learn more>

PPSU 9X04488 (PDX-04488): Flame-Retardant PPSU for Injection Molding Learn more>

PSU P-1700:High-Strength & Heat-Resistant Polysulfone for Electronics, Medical Learn more>