PRODUCTS

Introduction to mLLDPE PF1315AZ for Flexible Packaging

Product Struction

MLLDPE PF1315AZ Introduction

mLLDPE PF1315AZ is an additive free metallocene linear low density polyethylene (mLLDPE) base resin with excellent mechanical properties and resistance to environmental stress cracking (ESCR). Its low density characteristics allow the material to exhibit excellent flexibility while maintaining high tensile strength and puncture resistance, and maintain stable physical performance within a wide processing window.

1、MLLDPE Material Property

Metallocene LLDPE PF1315AZ is suitable for processing such as Injection Molding, Extrusion Coating and Lamination. Its excellent Heat Sealability and processing adaptability give it a significant advantage in flexible packaging films, composite packaging materials and multi-layer co-extruded structures. In addition, mLLDPE PF1315AZ's high melt flow rate (MFR) and excellent processing stability make it ideal for Masterbatch Carrier Resin and extrusion coating processes, ensuring excellent thickness uniformity and quality consistency.

2、MLLDPE Pellets Applications

Based on its excellent comprehensive performance, mLLDPE PF1315AZ is widely used in the field of plastic processing, especially for the production of high-performance flexible packaging, heat sealing layer and multi-layer composite film, providing reliable performance guarantee and processing convenience for the end product.

3、MLLDPE Resin Parameters

| Hardness | Condition | Standard | Value | Unit | |||

| Shore | Hardness D | ISO 868 | 46 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ISO 527 | 22 | % | |||

| Elongation | Break | ISO 527 | 600 | % | |||

| Flexural | Modulus 23°C | ISO 178 | 244 | MPa | |||

| Izod | Notch Impact -20°C Type A | ISO 180 | 71 | kJ/m² | |||

| Tensile | Modulus | ISO 527 | 217 | MPa | |||

| Tensile | Strength Yield 23°C | ISO 527 | 9 | MPa | |||

| Tensile | Strength Break | ISO 527 | NOBREAK | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | 23°C | ISO 1183 | 914 | kg/m³ | |||

| Environmental | Stress Crack Resistance | INTERNAL METHOD | 175 | hr | |||

| Melt | Index 190°C 2.16kg | ISO 1133 | 15 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Avg. | Heat of Fusion | ASTM D3418 | 104 | J/g | |||

| Crystallization | Temperature | INTERNAL METHOD | 100~84 | °C | |||

| Melting | Temperature DSC 10°C/min 2nd Heating | ISO 11357 | 96~114 | °C | |||

| Vicat | Softening Temperature 50°C/hr 10N | ISO 306 | 90 | °C | |||

Click here to download TDS for mLLDPE PF1315AZ

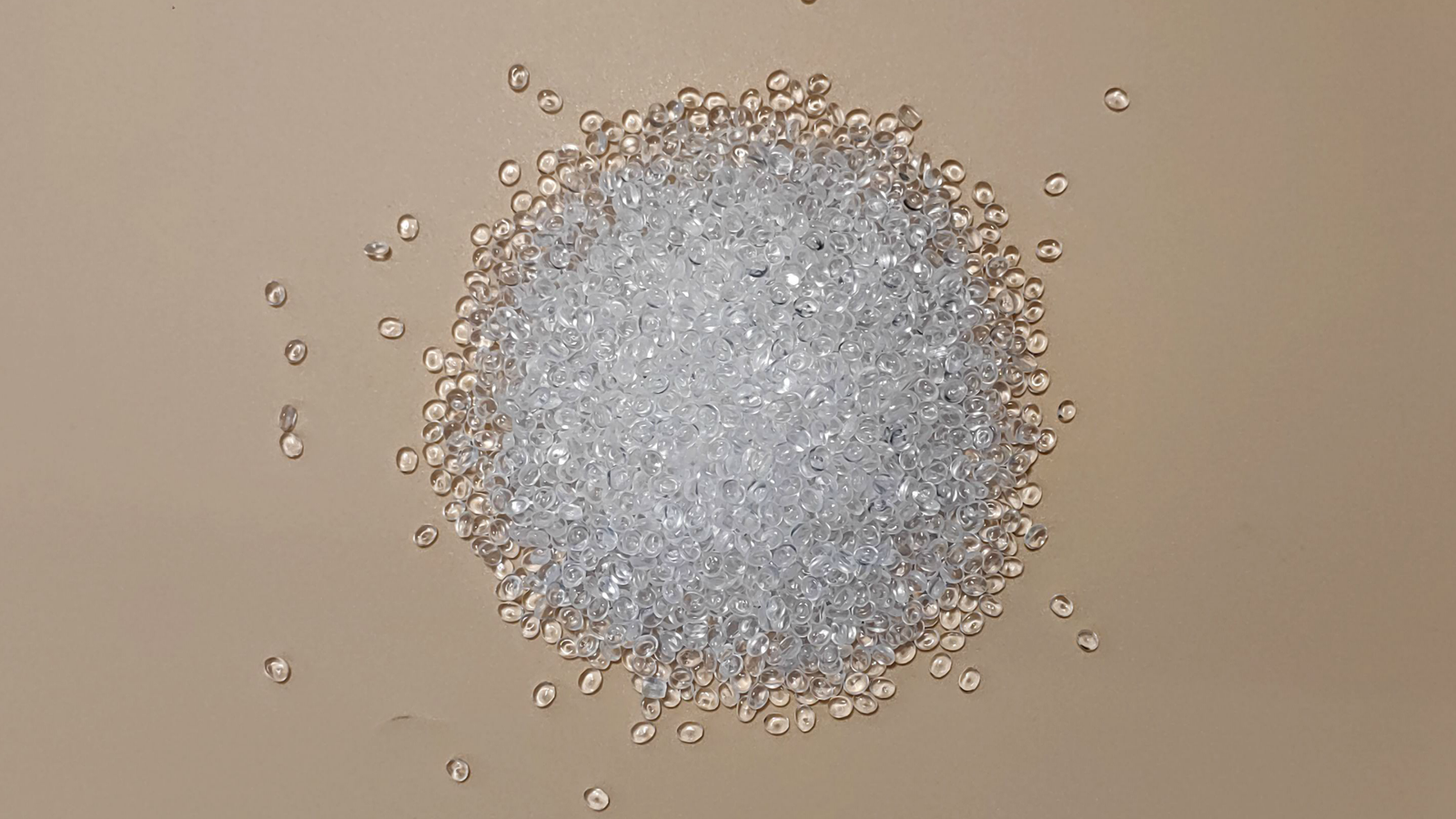

4、Metallocene LLDPE Granule Display

【Related Recommendations】

mLLDPE 8784MK: High-Performance mLLDPE for Barrier Films & Liquid Packaging Learn more>

mLLDPE HP1018BM: High-Impact Resistant mLLDPE for Packaging & Film Applications Learn more>

mLLDPE D174: High-Toughness Film-Grade Copolymer for Extrusion Applications Learn more>