PRODUCTS

Overview of mLLDPE PF1320AZ Resin for Masterbatch and Coatings

Product Struction

MLLDPE PF1320AZ Resin Introduction

mLLDPE PF1320AZ is an additive-free, linear low-density polyethylene (mLLDPE) resin that is widely used in masterbatch, extrusion coatings, and composite molding. Its high flowability makes it suitable for injection molding, blow molding, and extrusion processes, and is able to meet the needs of efficient production and complex structural molding. With its excellent processability, mLLDPE PF1320AZ excels in the production of products such as thin-walled products and high-performance films.

The excellent mechanical properties and stress cracking resistance of the mLLDPE resin enable it to maintain a stable structure and good physical properties during long-term use. Its superior sealing and high impact resistance enhance product quality and durability, making it ideal for masterbatch and composite applications. For high-strength requirements, mLLDPE PF1320AZ resin can provide higher rigidity and impact resistance.

mLLDPE PF1320AZ has good transparency, high-temperature and aging resistance, which makes it the first choice for high-performance film and optical-grade materials, especially for casting film special materials and film-grade applications. Its excellent heat resistance and thermal deformation temperature enable it to meet the needs of high-temperature processing and long-term use.

As a food contact grade material, mLLDPE PF1320AZ resin has excellent physical stability and safety under high-temperature environments and is widely used in the field of food packaging. It is non-toxic and harmless, meets food-grade standards, and is ideal for high-transparency, high-gloss food packaging films and other food contact products.

MLLDPE PF1320AZ Resin Parameters

| Hardness | Condition | Standard | Value | Unit | |||

| Shore | Hardness D | ISO 868 | 46 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ISO 527 | 18 | % | |||

| Elongation | Break | ISO 527 | 600 | % | |||

| Flexural | Modulus 23°C | ISO 178 | 260 | MPa | |||

| Izod | Notch Impact -20°C Type A | ISO 180 | 70 | kJ/m² | |||

| Tensile | Modulus | ISO 527 | 225 | MPa | |||

| Tensile | Strength Yield 23°C | ISO 527 | 8 | MPa | |||

| Tensile | Strength Break | ISO 527 | NOBREAK | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | 23°C | ISO 1183 | 913 | kg/m³ | |||

| Environmental | Stress Crack Resistance | INTERNAL METHOD | 29 | hr | |||

| Melt | Index 190°C 2.16kg | ISO 1133 | 20 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Avg. | Heat of Fusion | ASTM D3418 | 101 | J/g | |||

| Crystallization | Temperature | INTERNAL METHOD | 101~82 | °C | |||

| Melting | Temperature DSC 10°C/min 2nd Heating | ISO 11357 | 96~114 | °C | |||

| Vicat | Softening Temperature 50°C/hr 10N | ISO 306 | 88 | °C | |||

Click here to download TDS for mLLDPE PF1320AZ

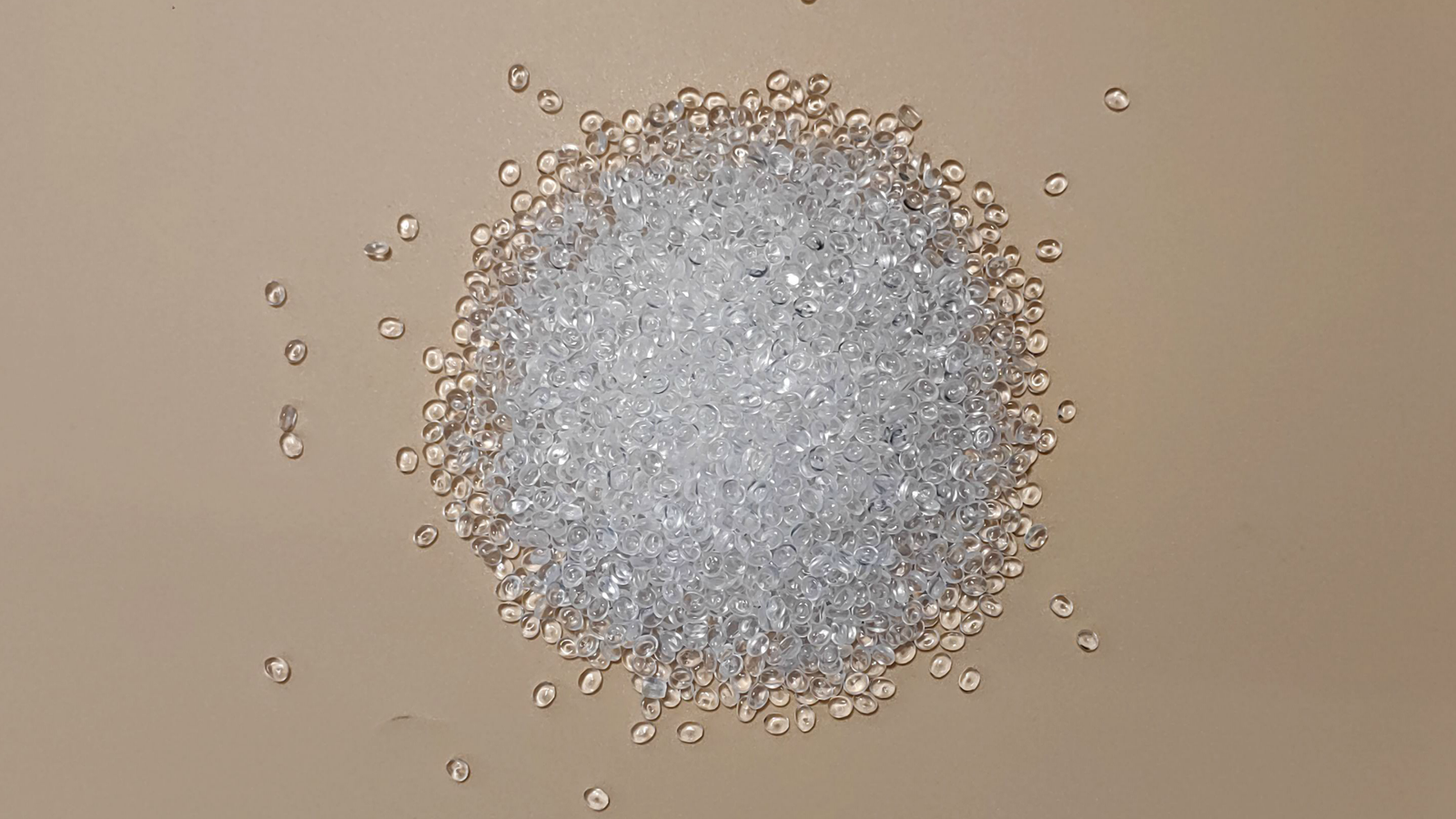

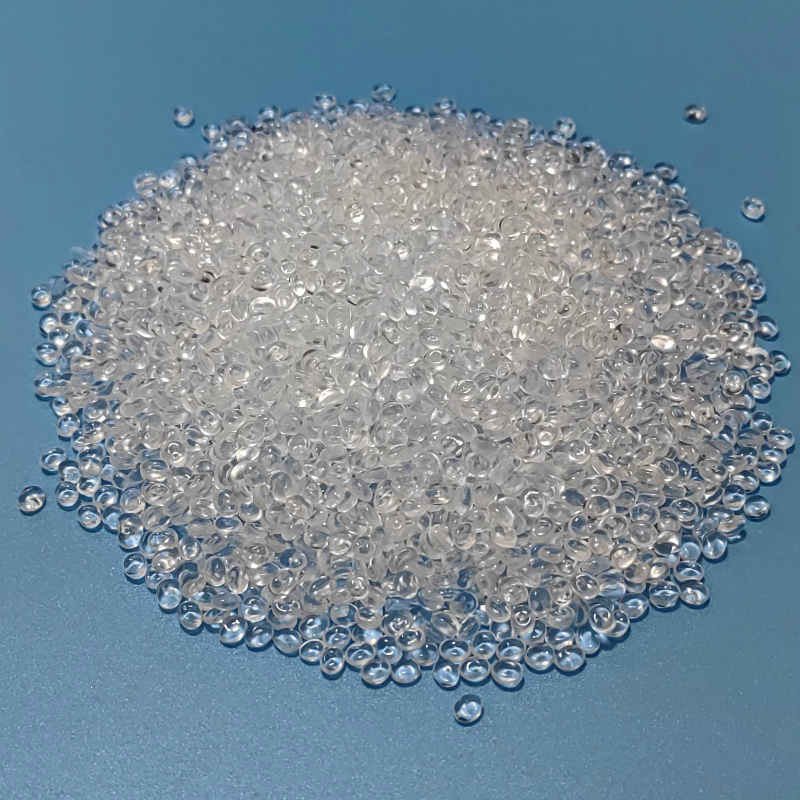

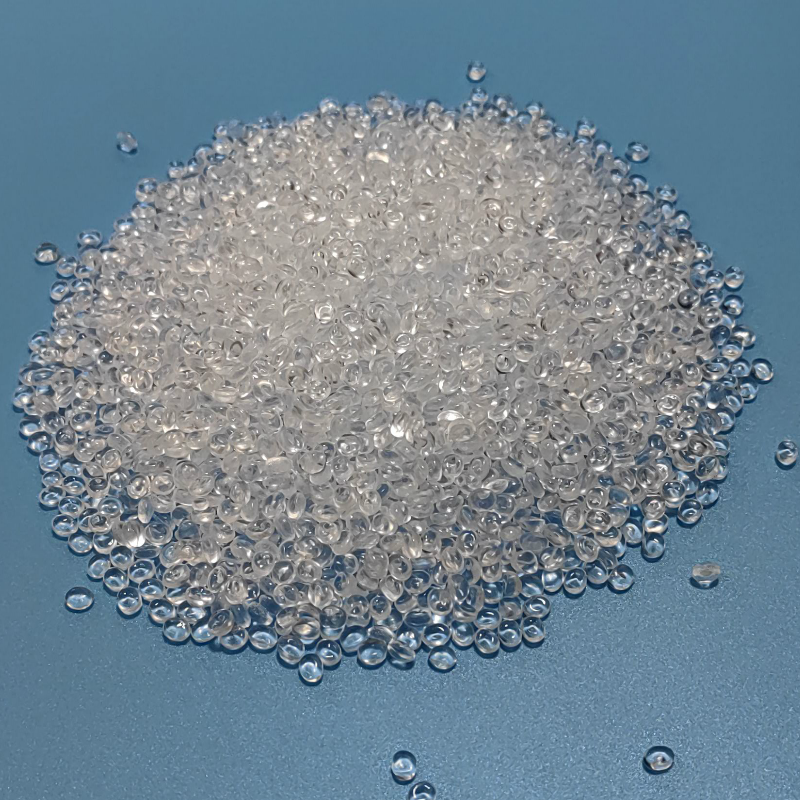

MLLDPE PF1320AZ Resin Display

Need to know the technical parameters of mLLDPE PF1320AZ Resin? Contact us for a TDS and request a free sample!

【Related Recommendations】

mLLDPE D173: High-Clarity, Tough Film-Grade Mlldpe Resin for Packaging Learn more>

mLLDPE LL7835A injection grade Heavy duty film application plastic raw material Learn more>

Metallocene mLLDPE LL7810A injection molding grade plastic raw material Learn more>