PRODUCTEN

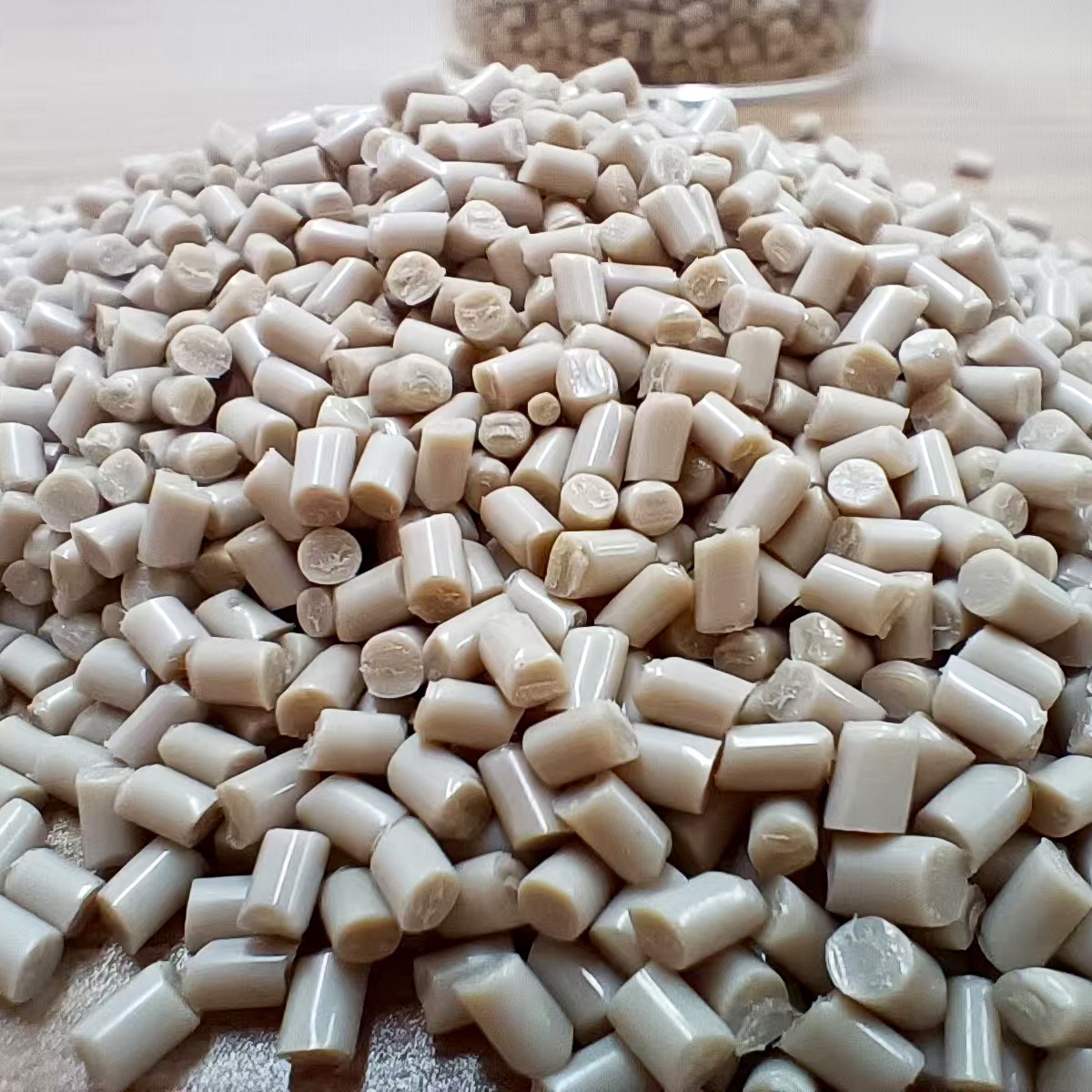

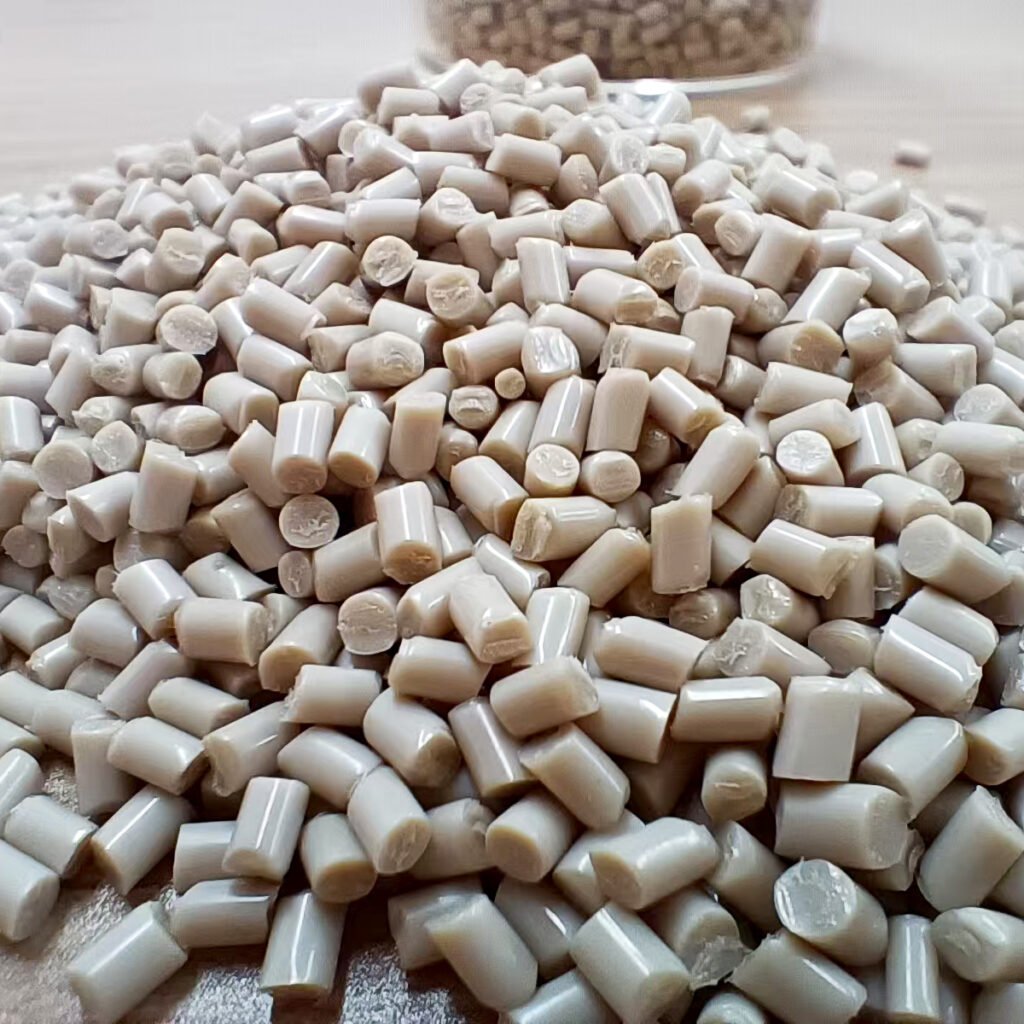

VESTAKEEP® 2000 FC30: Self-Lubricating Polyether Ether Ketone

Productconstructie

I. Product Overview

VESTAKEEP® 2000 FC30 is a composite Polyether Ether Ketone (PEEK) material from Evonik. It uses a PEEK matrix and is composited with carbon fiber (CF), PTFE (polytetrafluoroethylene), and graphite (GR).

This unique ternary reinforcement system combines high rigidity, self-lubrication, chemical resistance, and flame retardancy, making it an ideal choice for structural components requiring high sliding friction and high temperatures.

For manufacturers seeking to achieve both lightweight and maintenance-free components, PEEK 2000 FC30 offers a stable, proven, and mass-producible technology path.

II. Material Logic of Composite Structures

PEEK 2000 FC30's performance advantages stem from the synergy of its multiple phases:

・Carbon fiber reinforcement: Significantly improves tensile modulus and dimensional stability;

・PTFE lubrication: Forms a solid friction film, reducing wear and heat generation;

・Graphite thermal conductivity and wear resistance: Ensures low friction and smooth movement even under high loads.

This multi-component composite solution is one of the innovative directions in the Polyether Ether Ketone system. Its core value lies in "enabling plastics to replace metal under extreme operating conditions."

III. Core Performance Characteristics

・Strong chemical resistance: Suitable for parts exposed to solvents, fuels, or acidic and alkaline media;

・Excellent flame retardancy and safety: Meets UL V-0 rating and self-extinguishes upon removal of the ignition source;

・Low friction coefficient and self-lubricating operation: Ensures smooth movement without the need for additional lubrication;

・Excellent thermal stability: Maintains structural integrity in environments exceeding 600°C;

・Dimensional stability and low shrinkage: Ideal for precision injection molding and wear-resistant assemblies.

These characteristics make it an outstanding choice for industrial automation, energy equipment, and precision transmission.

IV. Typical Applications

VESTAKEEP® 2000 FC30 is primarily used in:

・Bearings and bushings: achieving lubrication-free, low-noise operation;

・Gear and slide components: exhibiting superior wear resistance compared to unfilled PEEK;

・Pump and valve components: offering high-temperature and long-term media resistance;

・Automotive and aviation system components: offering high strength, low weight, and excellent fatigue resistance.

For engineering systems seeking long-term reliability and low maintenance costs, Polyether Ether Ketone composites are becoming a leading alternative.

V. VESTAKEEP® 2000 FC30 Data Sheet

| Mechanisch gedrag | Voorwaarde | Waarde |

| Verlenging | 2.0 | |

| Treksterkte | 21000 | |

| Trekmodulus | 1670000 | |

| Charpy Un-notch-impact | 19 | |

| Charpy Un-notch-impact | 19 | |

| Charpy Notch-impact | 2.4 | |

| Charpy Notch-impact | 2.9 | |

| Thermisch | Voorwaarde | Waarde |

| HDT | 639 | |

| HDT | 608 | |

| Smelttemperatuur | 644 | |

| CLE | 22~55℃ | 1.1E-5 |

| Vicat-verzachtingstemperatuur | 635 | |

| Vicat-verzachtingstemperatuur | 644 | |

| Fysieke eigendom | Voorwaarde | Waarde |

| Krimp | 0.40 | |

| Krimp | 0.10 | |

| Dikte | 1.45 | |

| Smeltindex | 15 | |

| Elektrische eigenschappen | Voorwaarde | Waarde |

| Diëlektrische constante | 6.10 | |

| Diëlektrische constante | 4.90 | |

| Volumeweerstand | 1E7 | |

| Oppervlakteweerstand | 1E5 | |

| Ontvlambaarheid | Voorwaarde | Waarde |

| GWFI | 2.03mm | 1760 |

| GWIT | 2.03mm | 1650 |

| Vlamclassificatie | 1.52mm | V-0 |

VI. Processing Compatibility

This material is injection-molding-grade pelletized with high flowability and a stable crystallization rate, making it easily adaptable to complex mold structures.

Its high heat deflection temperature and low shrinkage enable consistent production quality in high-precision injection molding equipment, eliminating the need for additional coatings or secondary processing.

For manufacturers primarily working with wear-resistant or high-temperature components, this processing stability translates to higher yields and lower maintenance costs.

VII. FAQs for Buyers

Q1: What is the difference between PEEK 2000 FC30 and ordinary PEEK?

A: Ordinary PEEK has high strength but a relatively high coefficient of friction. PEEK 2000 FC30, through triple modification with carbon fiber, PTFE, and graphite, achieves a balance between strength, wear resistance, and lubricity, making it more suitable for moving parts.

Q2: Can it replace metal parts?

A: In many gear, slip ring, and bushing applications, it can replace bronze or stainless steel parts, reducing weight by approximately 40% and eliminating the need for lubricants.

Q3: Can it be used in food or medical applications?

A: PEEK 2000 FC30 is primarily an industrial wear-resistant grade. For food contact applications, FDA-certified grades with the same base material are available.

Q4: What services does Juyuan provide?

A: We offer authentic granules in stock, sample molds, technical parameter matching, selection recommendations, and support small-batch verification.

VIII.Similar Recommendations

If you are evaluating Polyether Ether Ketone materials for different applications, you may consider other reinforced, wear-resistant, or antistatic grades (such as the PEEK CF series and PEEK FC series).

We can recommend the most suitable grade and process window based on the application scenario (rotation speed, temperature, and friction environment).

IX. Juyuan Supply and Support

As a supplier with over 20 years of experience in international plastics trading, Juyuan specializes in the international supply and application guidance of engineering plastic raw materials.

| Product Grade | Soortelijk gewicht | Treksterkte | Verlenging | Mold Shrinkage | Trekmodulus | HDT |

| 2000 CF30 | 1.38 g/cm³ | 34800 psi | 2.0 % | 0.40 % | 3340000 psi | 644 ℉ |

| 2000 G | 1.3 g/cm³ | 100 MPa | 5 % | 1.1 % | 3700 MPa | 205 °C |

| 4000 GF30 | 1.50 g/cm³ | 23900 psi | 2.0 % | 0.60 % | 1600000 psi | 635 ℉ |

| 4000 FC30 | 1.45 | 20300 | 2.0 | 0.40 | 1670000 | 626 |

| 2000 FP | 1.3 g/cm³ | 100 MPa | 5 % | 3700 MPa | 205 °C | |

| 4000 FP | 1.3 g/cm³ | 96 MPa | 5 % | 3500 MPa | 205 °C | |

| 4000 CF30 | 1.40 g/cm³ | 34800 psi | 2.0 % | 0.40 % | 3340000 psi | 635 ℉ |

| 2000 GF30 | 1.50 g/cm³ | 23900 psi | 2.0 % | 0.70 % | 1600000 psi | 640 ℉ |

| 4000 GF30 BK | 1.5 g/cm³ | 160 MPa | 2 % | 0.3 % | 11000 MPa | 335 °C |

| 4000 CC20 | 1.49 g/cm³ | 13800 psi | 5.0 % | 595000 psi | 410 ℉ | |

| 2200 G | 1.3 g/cm³ | 100 MPa | 5 % | 1.1 % | 3700 MPa | |

| 4000 CFL30 | 1400 kg/m³ | 245 MPa | 2 % | 24000 MPa | ||

| 4000 CF20 | 1360 kg/m³ | 200 MPa | 2.5 % | 0.7 % | 16859 MPa | |

| 1000 UFP10 | 1.3 g/cm³ | 105 MPa | 5.5 % | 3800 MPa | 205 °C | |

| 5000 FP | 1.3 g/cm³ | 95 MPa | 5 % | 0.9 % | 3400 MPa | |

| 4000 G BK | 1.3 g/cm³ | 95 MPa | 5 % | 0.9 % | 3500 MPa | |

| Ultimate | 1.30 g/cm³ | 13800 psi | 5.0 % | 1.1 % | 493000 psi | |

| 2000 FP20 | 1.3 g/cm³ | 100 MPa | 5 % | 3700 MPa | 205 °C |

We offer Polyether Ether Ketone materials from brands such as Evonik, Solvay, and Victrex, and through stable global channels, we help customers reduce procurement risks and inventory costs.

X. Conclusion

Evonik VESTAKEEP® 2000 FC30 represents another leap forward for Polyether Ether Ketone materials in the composite engineering field.

It is more than just a "wear-resistant plastic," but a sustainable metal replacement solution that operates stably under extreme temperature and friction conditions. For buyers who value performance reliability and processing consistency, this material will be a long-term option worthy of special attention.

【Gerelateerde aanbevelingen】

Fluorseals FLUTECK™ K300: Food-Grade PEEK Resin Meer informatie>

Hippe PEEK BG: Balancing Rigidity & Heat Resistance PEEK Engineering Plastic Meer informatie>

PA6 vs POM: A classic comparison and selection guide for engineering plastics Meer informatie>