PRODUCTOS

Introducción a mLLDPE PF1315AZ para envases flexibles

Estructura del producto

Introducción al MLLDPE PF1315AZ

mLLDPE PF1315AZ es una resina de polietileno lineal de baja densidad (mLLDPE) de metaloceno sin aditivos con excelentes propiedades mecánicas y resistencia al agrietamiento por tensión ambiental (ESCR). Sus características de baja densidad le permiten exhibir una excelente flexibilidad, manteniendo alta resistencia a la tracción y a la perforación, y manteniendo un rendimiento físico estable dentro de un amplio rango de procesamiento.

1. Propiedades del material MLLDPE

El LLDPE metaloceno PF1315AZ es apto para procesos como moldeo por inyección, recubrimiento por extrusión y laminación. Su excelente termosellabilidad y adaptabilidad al procesamiento le confieren una ventaja significativa en películas de embalaje flexible, materiales de embalaje compuestos y estructuras coextruidas multicapa. Además, su alto índice de fluidez (MFR) y su excelente estabilidad de procesamiento lo hacen ideal para resinas portadoras de masterbatch y procesos de recubrimiento por extrusión, garantizando una excelente uniformidad de espesor y calidad.

2. Aplicaciones de los pellets de MLLDPE

Basado en su excelente desempeño integral, mLLDPE PF1315AZ es ampliamente utilizado en el campo del procesamiento de plástico, especialmente para la producción de envases flexibles de alto rendimiento, capas de sellado térmico y películas compuestas multicapa, brindando una garantía de desempeño confiable y conveniencia de procesamiento para el producto final.

3. Parámetros de la resina MLLDPE

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Costa | Dureza D | ISO 868 | 46 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Producir | ISO 527 | 22 | % | |||

| Alargamiento | Romper | ISO 527 | 600 | % | |||

| Flexión | Módulo 23°C | ISO 178 | 244 | MPa | |||

| Izod | Muesca de impacto -20 °C tipo A | ISO 180 | 71 | kJ/m² | |||

| De tensión | Módulo | ISO 527 | 217 | MPa | |||

| De tensión | Resistencia Rendimiento 23°C | ISO 527 | 9 | MPa | |||

| De tensión | Rotura de fuerza | ISO 527 | SIN RUPTURA | MPa | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | 23ºC | ISO 1183 | 914 | kg/m³ | |||

| Ambiental | Resistencia al agrietamiento por tensión | MÉTODO INTERNO | 175 | hora | |||

| Derretir | Índice 190°C 2,16kg | ISO 1133 | 15 | g/10min | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Promedio. | Calor de fusión | Norma ASTM D3418 | 104 | J/g | |||

| Cristalización | Temperatura | MÉTODO INTERNO | 100~84 | °C | |||

| Derritiendo | Temperatura DSC 10°C/min 2º Calentamiento | ISO 11357 | 96~114 | °C | |||

| vicat | Temperatura de ablandamiento 50°C/h 10N | ISO 306 | 90 | °C | |||

Haga clic aquí para descargar la ficha técnica del mLLDPE PF1315AZ

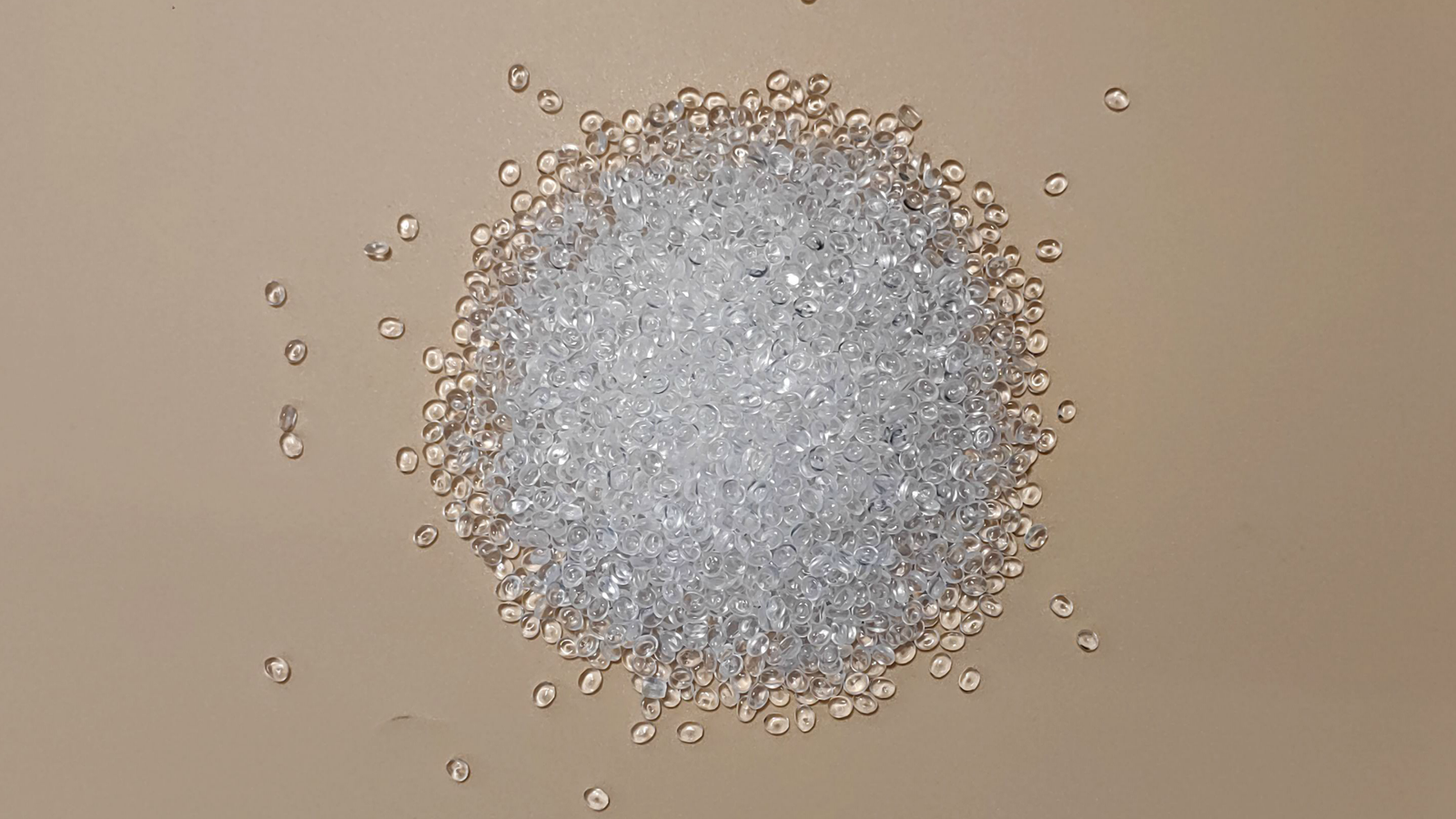

4、Exhibición de gránulos de LLDPE de metaloceno

【Recomendaciones relacionadas】

mLLDPE 8784MK: mLLDPE de alto rendimiento para películas de barrera y envasado de líquidos Más información>

mLLDPE HP1018BM: mLLDPE resistente a altos impactos para aplicaciones de embalaje y películas Más información>

mLLDPE D174: Copolímero de película de alta tenacidad para aplicaciones de extrusión Más información>