PRODUCTOS

PPSU R-5000 CL 301 resistente a altas temperaturas para aplicaciones médicas y alimentarias

Estructura del producto

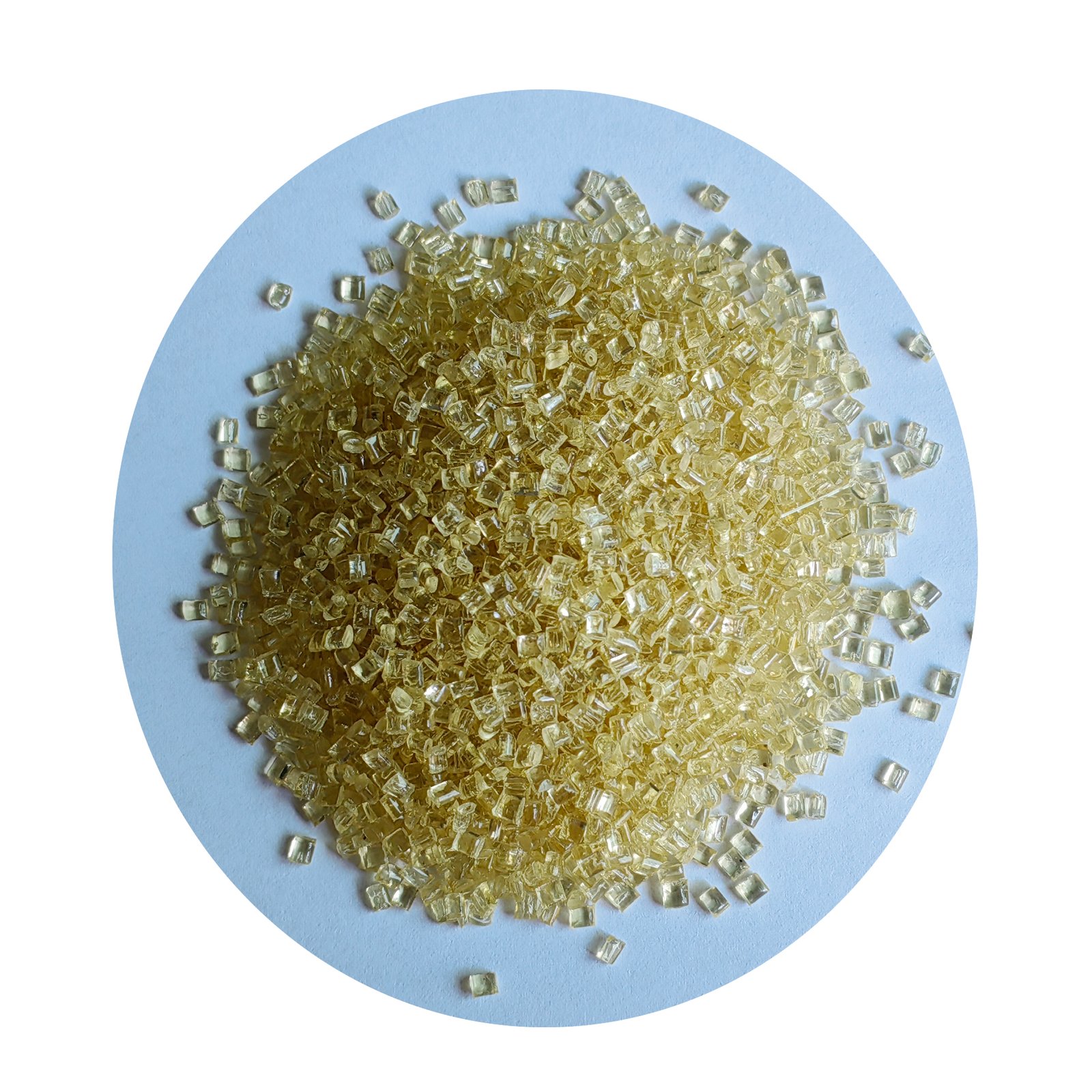

PPSU R-5000 CL301 is a high-performance polysulfone (PPSU) material, characterized by its transparent appearance and versatility in processing. It is suitable for a variety of manufacturing techniques, including injection molding, extrusion molding, blow molding, thermoforming, and CNC machining. This material achieves a flame retardancy rating of V-0 5VA, fully complying with international fire safety standards and regulations.

Excellent performance of the PPSU R-5000 CL 301:

The PPSU R-5000 CL 301 offers several outstanding material properties, including:

Flame retardant: V-0 5VA flame retardant grade to ensure product safety and reliability.

High temperature resistance: high heat resistance, can withstand high temperature environment.

Hydrolysis resistance: suitable for humid environment, prolong product life.

Food contact level: meets food safety standards and can directly contact food.

Medical grade: Good biocompatibility and can be used in medical devices.

In addition, the PPSU R-5000 CL 301 has the following features:

Steam resistance, heat aging: suitable for high temperature disinfection environment.

High toughness, stress cracking resistance: ensure product durability.

Anti-gamma ray, radiation sterilization: suitable for sterilization of medical equipment.

Acid, alkali, chemical resistance: suitable for a variety of chemical environments.

Dimensional stability, good electrical performance: ensure product accuracy and reliability.

The wide application of PPSU R-5000 CL 301:

With its superior performance, the PPSU R-5000 CL 301 is widely used in the following areas:

Medical equipment: surgical instruments, diaphragms, medical care supplies, etc.

Food service applications: food processing equipment, tableware, etc.

Automotive applications: auto parts, etc.

Dental applications: Dental instruments, etc.

Get started with a free consultation—contact us to find out how we can help you!

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Dieléctrico | Fortaleza | Norma ASTM D149 | 14 | kilovoltios/mm | |||

| Volumen | Resistividad | Norma ASTM D257 | 9E+15 | Ω.cm | |||

| Moldeo por extrusión | Condición | Estándar | Valor | Unidad | |||

| Adaptador | Temperatura | 327~371 | °C | ||||

| Morir | Temperatura | 327~371 | °C | ||||

| Seco | Temperatura | 171 | °C | ||||

| Seco | Tiempo | 4.0 | hora | ||||

| Derretir | Temperatura | 343~399 | °C | ||||

| Zona | 1 temperatura | 338~388 | °C | ||||

| Zona | 2 temperatura | 338~388 | °C | ||||

| Zona | 3 temperatura | 338~388 | °C | ||||

| Zona | 4 temperatura | 338~388 | °C | ||||

| Zona | 5 temperatura | 338~388 | °C | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Fuego | Clasificación NC 0,36 mm | UL94 | V-0 | ||||

| Fuego | Clasificación de todos los colores 0,75 mm | UL94 | V-0 | ||||

| Fuego | Clasificación Todos los colores 1,5 mm | UL94 | V-0 | ||||

| Fuego | Clasificación Todos los colores 3,0 mm | UL94 | V-0 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 3,2 mm | Norma ASTM D638 | 7.2 | % | |||

| Alargamiento | Romper 3,2 mm | Norma ASTM D638 | 60~120 | % | |||

| Flexión | Fuerza 5.0%Stren 3.2mm | Norma ASTM D790 | 91.0 | MPa | |||

| Flexión | Módulo 3,2 mm | Norma ASTM D790 | 2410 | MPa | |||

| Izod | Impacto de muesca 3,2 mm | Norma ASTM D256 | 690 | j/m | |||

| De tensión | Módulo 3,2 mm | Norma ASTM D638 | 2340 | MPa | |||

| De tensión | Fuerza 3,2 mm | Norma ASTM D638 | 69.6 | MPa | |||

| De tensión | Resistencia al impacto 3,2 mm | Norma ASTM D1822 | 399 | kJ/m² | |||

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Refractivo | Índice | Norma ASTM D542 | 1.672 | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D792 | 1.29 | gramos/cm³ | ||||

| Derretir | Índice 365°C 5kg | Norma ASTM D1238 | 14~20 | g/10min | |||

| Contracción | Flujo 3,2 mm | Norma ASTM D955 | 0.70 | % | |||

| Agua | Absorción 24h | Norma ASTM D570 | 0.37 | % | |||

| Agua | Equilibrio de absorción | Norma ASTM D570 | 1.1 | % | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| CLE | Flujo 3,2 mm | Norma ASTM D696 | 5.6E-5 | cm/cm/°C | |||

| Vaso | Temperatura de transición | ASTM E1356 | 220 | °C | |||

| HDT | Sin recocer 1.8MPa 3.2mm | Norma ASTM D648 | 207 | °C | |||

| UL | Condición | Estándar | Valor | Unidad | |||

| Arco | Resistencia | ASTM D495 | 5 | SOCIEDAD ANÓNIMA | |||

| Comparativo | Índice de seguimiento | IEC 60112 | 5 | SOCIEDAD ANÓNIMA | |||

| Hola | NC 0.36mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | ALL 0.75mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | TODOS 1,5 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | TODOS 3,0 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Alta Velocidad | UL 746A | 0 | SOCIEDAD ANÓNIMA | ||||

| HWI | NC 0.36mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| HWI | ALL 0.75mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| HWI | TODOS 1,5 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| HWI | TODOS 3,0 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| RTI | Elec NC 0.36mm | UL 746B | 160 | °C | |||

| RTI | Eléctrico TODO 0,75 mm | UL 746B | 180 | °C | |||

| RTI | Eléctrico TODOS 1,5 mm | UL 746B | 180 | °C | |||

| RTI | Eléctrico TODO 3.0mm | UL 746B | 180 | °C | |||

| RTI | Imp NC 0.36mm | UL 746B | 160 | °C | |||

| RTI | Imp ALL 0.75mm | UL 746B | 170 | °C | |||

| RTI | Diablillo TODO 1,5 mm | UL 746B | 170 | °C | |||

| RTI | Diablillo TODOS 3,0 mm | UL 746B | 170 | °C | |||

| RTI | Str NC 0.36mm | UL 746B | 160 | °C | |||

| RTI | Str ALL 0.75mm | UL 746B | 180 | °C | |||

| RTI | Str TODOS 1,5 mm | UL 746B | 180 | °C | |||

| RTI | Tira TODOS 3,0 mm | UL 746B | 180 | °C | |||

| UL | FlameRating NC 0.36mm | UL94 | V-0 | ||||

| UL | Clasificación de llama TODOS 0,75 mm | UL94 | V-0 | ||||

| UL | Clasificación de llama TODOS 1,5 mm | UL94 | V-0 | ||||

| UL | Clasificación de llama TODOS 3,0 mm | UL94 | V-0 | ||||