PRODUCTOS

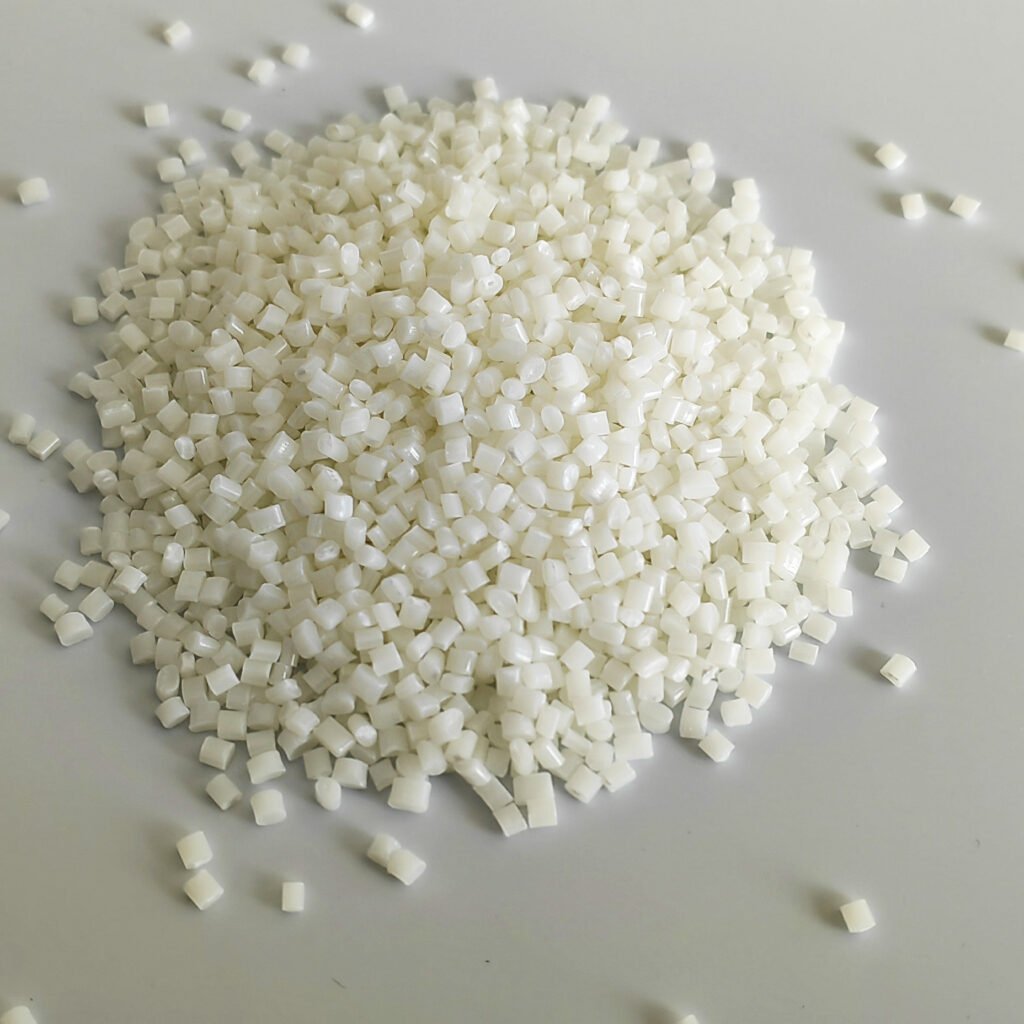

Chimei ABS PA-746 | High-Flow ABS Raw Material for Automotive

Estructura del producto

What is ABS Raw Material?

Chi Mei ABS PA-746 is an injection-grade ABS Raw Material. With its excellent appearance and high fluidity, it has become an ideal choice for the manufacturing of automotive, office equipment and household appliance shells. This material not only ensures the forming accuracy but also has good processing adaptability, meeting the requirements of thin-walled products and complex structural components.

01 | Material Highlights and Features

High-flow design: PA-746 enables rapid filling of complex molds during the injection molding process, ensuring high-quality molding of thin-walled structures and intricate details.

Excellent Surface Appearance: The material's smooth and uniform surface reduces the need for post-processing polishing or painting, making it suitable for products requiring high visual appeal.

Strong Injection Molding Adaptability: Compatible with various injection molding machines and mold designs, it provides stable molding and reduces scrap rates.

Optimized Additives: Contains lubricants and release agents to improve processing efficiency and mold release.

02 | Applications

Automotive Parts: Instrument panels, door trims, and interior trim, where appearance and impact resistance are critical.

Office Equipment: Printer and copier housings, keyboards, and other applications, where injection molding accuracy and surface finish are critical.

Appliance Housings: TV, air conditioner, and small appliance housings, achieving both lightweight and thin-wall designs.

Complex Thin-Wall Structural Parts: PA-746's high fluidity meets the injection molding requirements of complex molds and microstructures.

03 | Processing and Processing Advantages

Amplia ventana de procesamiento: PA-746's strong adaptability to temperature and pressure fluctuations reduces production risks.

High-Efficiency Injection Molding: The material's high fluidity shortens production cycles while ensuring product dimensional accuracy.

High Stability: Maintains consistent mechanical and thermal properties across multiple production batches, reducing quality fluctuations.

04 | Innovative Value and Competitive Advantages

Thin-Wall Part Optimization: Reduces material usage and facilitates lightweight design.

Leading Overall Performance: Balances appearance, mechanical properties, and processability, making it more competitive than similar ABS Raw materials.

Multi-Industry Applicability: Suitable for automotive, home appliances, and office equipment, meeting diverse customer needs.

05 | Chi Mei ABS PA-746 Data Sheet

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Fuego | Clasificación Todos los colores 1,5 mm | UL94 | media pensión | ||||

| Fuego | Clasificación Todos los colores 3,0 mm | UL94 | media pensión | ||||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| rockwell | Dureza R (escala) | Norma ASTM D785 | 118 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Charpy | Impacto de muesca 23°C | ISO 179 | 30 | kJ/m² | |||

| Charpy | Impacto de muesca -30°C | ISO 179 | 14 | kJ/m² | |||

| Alargamiento | 6 mm/min | Norma ASTM D638 | 30 | % | |||

| Alargamiento | 50 mm/min | ISO 527 | 30 | % | |||

| Flexión | Resistencia 2,8 mm/min | Norma ASTM D790 | 650 | kg/cm² | |||

| Flexión | Resistencia 2,0 mm/min | ISO 178 | 60 | MPa | |||

| Flexión | Módulo 2,8 mm/min | Norma ASTM D790 | 22000 | kg/cm² | |||

| Flexión | Módulo 2,0 mm/min | ISO 178 | 1.8 | GPA (médico general) | |||

| Izod | Muesca de impacto 23 °C 6,4 mm | Norma ASTM D256 | 26 | kg-cm/cm | |||

| Izod | Muesca de impacto 23 °C 3,2 mm | Norma ASTM D256 | 32 | kg-cm/cm | |||

| Izod | Impacto de muesca 23°C | ISO 180 | 28 | kJ/m² | |||

| Izod | Muesca de impacto -30°C | ISO 180 | 12 | kJ/m² | |||

| De tensión | Resistencia a la fluencia 6 mm/min | Norma ASTM D638 | 415 | kg/cm² | |||

| De tensión | Rendimiento de resistencia 50 mm/min. | ISO 527 | 39 | MPa | |||

| De tensión | Resistencia a la rotura 50 mm/min | ISO 527 | 29 | MPa | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | 23ºC | Norma ASTM D792 | 1.03 | gramos/cm³ | |||

| Densidad | 23ºC | ISO 1183 | 1.03 | gramos/cm³ | |||

| Derretir | Índice 200°C 5kg | Norma ASTM D1238 | 3.0 | g/10min | |||

| Derretir | Índice 220°C 10kg | ISO 1133 | 29 | cm³/10min | |||

| Contracción | ISO 294 | 0.4~0.7 | % | ||||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| CLE | ISO 11359 | 9.2E-5 | cm/cm/°C | ||||

| HDT | Recocido 1,8 MPa | Norma ASTM D648 | 95 | °C | |||

| HDT | 1.8MPa sin recocer | Norma ASTM D648 | 85 | °C | |||

| HDT | 1.8MPa sin recocer | ISO 75 | 82 | °C | |||

| HDT | Recocido 1,8 MPa | ISO 75 | 96 | °C | |||

| vicat | Temperatura de ablandamiento 50°C/h 10N | Norma ASTM D1525 | 105 | °C | |||

| vicat | Temperatura de ablandamiento 50°C/h 10N | ISO 306 | 103 | °C | |||

| vicat | Temperatura de ablandamiento 50°C/h 50N | ISO 306 | 94 | °C | |||

| UL | Condición | Estándar | Valor | Unidad | |||

| Arco | Resistencia | ASTM D495 | 6 | SOCIEDAD ANÓNIMA | |||

| Comparativo | Índice de seguimiento | IEC 60112 | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | TODOS 1,5 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | TODOS 3,0 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Alta Velocidad | UL 746A | 2 | SOCIEDAD ANÓNIMA | ||||

| HWI | TODOS 1,5 mm | UL 746A | 4 | SOCIEDAD ANÓNIMA | |||

| HWI | TODOS 3,0 mm | UL 746A | 3 | SOCIEDAD ANÓNIMA | |||

| RTI | Eléctrico TODOS 1,5 mm | UL 746B | 85 | °C | |||

| RTI | Eléctrico TODO 3.0mm | UL 746B | 85 | °C | |||

| RTI | Diablillo TODO 1,5 mm | UL 746B | 80 | °C | |||

| RTI | Diablillo TODOS 3,0 mm | UL 746B | 80 | °C | |||

| RTI | Str TODOS 1,5 mm | UL 746B | 85 | °C | |||

| RTI | Tira TODOS 3,0 mm | UL 746B | 85 | °C | |||

| UL | Clasificación de llama TODOS 1,5 mm | UL94 | media pensión | ||||

| UL | Clasificación de llama TODOS 3,0 mm | UL94 | media pensión | ||||

| Volumen | Resistividad | Norma ASTM D257 | 1E+16 | Ω.cm | |||

06 | Customer Comments

"PA-746 maintains surface quality even under high-speed injection molding, significantly improving production efficiency."

"The success rate of molding thin-walled, complex parts is high, reducing post-processing and rework."

"The material has excellent stability and consistent performance from batch to batch, reducing scrap rates."

07 | FAQs

Q1: Is PA-746 suitable for high-speed injection molding?

A: Yes. Its high fluidity makes it suitable for high-speed injection molding and ensures uniform filling.

Q2: Is it suitable for thin-walled and complex structural parts?

A: Absolutely. It is optimized for thin-walled and microstructured parts.

Q3: What is its temperature resistance?

A: Under normal operating environments and injection molding conditions, its thermal and mechanical properties are stable.

Q4: Does it meet environmental standards?

A: It uses an environmentally friendly formula and is free of harmful heavy metals, making it suitable for home appliance and office equipment housings.

08 | Juyuan's Foreign Trade Supply Advantages

Global Sourcing Channels: A stable supply of Chimei ABS PA-746 and other high-quality ABS raw materials.

Efficient logistics and customs clearance ensure customers receive their products on time, reducing inventory pressure.

Technical support services provide material selection recommendations, process guidance, and solutions.

Customized services optimize packaging, specifications, and procurement solutions based on customer needs.

Summary

CHI Mei ABS PA-746, with its high flowability, excellent appearance, and stable performance, provides reliable solutions for the automotive, home appliance, and office equipment industries. Combined with Juyuan's international trade and technical support services, customers can efficiently secure a stable supply, optimize production, and enhance product value.

Haga clic aquí para descargar la ficha técnica del ABS PA-746

【Recomendaciones relacionadas】

ABS PA-709H:Resina ABS resistente y de bajo flujo para equipos de protección y equipaje Más información>

ABS PA-709P:ABS de alto impacto y retardante de llama para extrusión en tuberías Más información>

ABS PA-797:ABS ignífugo y químicamente duradero para utensilios de cocina Más información>