PRODUCTOS

Introducción al mLLDPE D174 de alta claridad para películas estirables

Estructura del producto

Introducción a MLLDPE D14

Polietileno de baja densidad ml-D174 Los pellets de plástico son un copolímero natural adecuado para procesos de extrusión y diseñados para aplicaciones de película delgada. El material adopta un copolímero de hexeno, que tiene alta claridad y alto brillo, por lo que la película que lo fabrica tiene una apariencia excelente. Además, mLLDPE D174 se caracteriza por una alta tenacidad y baja gravedad específica, lo que ayuda a reducir el peso del producto y mejorar la utilización del material al tiempo que mantiene buenas propiedades mecánicas.

El material también tiene un excelente rendimiento de sellado térmico, lo que puede satisfacer las necesidades de producción de películas fundidas y películas estirables, y garantizar que la película tenga un buen efecto de sellado durante el procesamiento y el uso. Combinado con las ventajas de la tecnología de catálisis de metaloceno, mLLDPE D174 proporciona una excelente estabilidad del proceso, lo que lo convierte en una excelente opción para materiales de película delgada de alto rendimiento en procesos de producción eficientes.

Parámetros del LLDPE de metaloceno

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Elmendorf | Película fundida de 25 μm con resistencia al desgarro | ASTM D1922 | 300 | gramo | |||

| Elmendorf | Película fundida de 25 μm con resistencia al desgarro xFlow | ASTM D1922 | 500 | gramo | |||

| Alargamiento | Película fundida Flow Break de 25 μm | Norma ASTM D882 | 550 | % | |||

| Alargamiento | Película fundida xFlow Break de 25 μm | Norma ASTM D882 | 680 | % | |||

| Descendente | Resistencia al impacto de peso Película fundida de 25 μm | ASTM D1709 | 260 | gramos por milésima de pulgada | |||

| Fricción | Película fundida de coeficiente de 25 μm | Norma ASTM D1894 | 1 | ||||

| De tensión | Módulo de flujo de película secante de 25 μm 1% | Norma ASTM D882 | 110 | MPa | |||

| De tensión | Película secante fundida 1% de módulo xFlow de 25 μm | Norma ASTM D882 | 117 | MPa | |||

| De tensión | Resistencia al flujo, película fundida de 25 μm | Norma ASTM D882 | 10 | MPa | |||

| De tensión | Película fundida de 25 μm con resistencia x rendimiento de flujo | Norma ASTM D882 | 9 | MPa | |||

| De tensión | Película fundida resistente a la rotura de flujo de 25 μm | Norma ASTM D882 | 54 | MPa | |||

| De tensión | Película fundida de resistencia xFlow Break de 25 μm | Norma ASTM D882 | 47 | MPa | |||

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Brillo | Película fundida de 60° y 25 μm | Norma ASTM D2457 | 140 | ||||

| Bruma | Película fundida de 25,00 μm | Norma ASTM D1003 | 2 | % | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D1505 | 0.918 | gramos/cm³ | ||||

| Derretir | Índice 190°C 2,16kg | Norma ASTM D1238 | 4.5 | g/10min | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Calor | Temperatura de sellado de película fundida de 25 μm, 0,5 s | ASTM F88 | 101 | °C | |||

Haga clic aquí para descargar TDS para Polietileno de baja densidad ml-D174

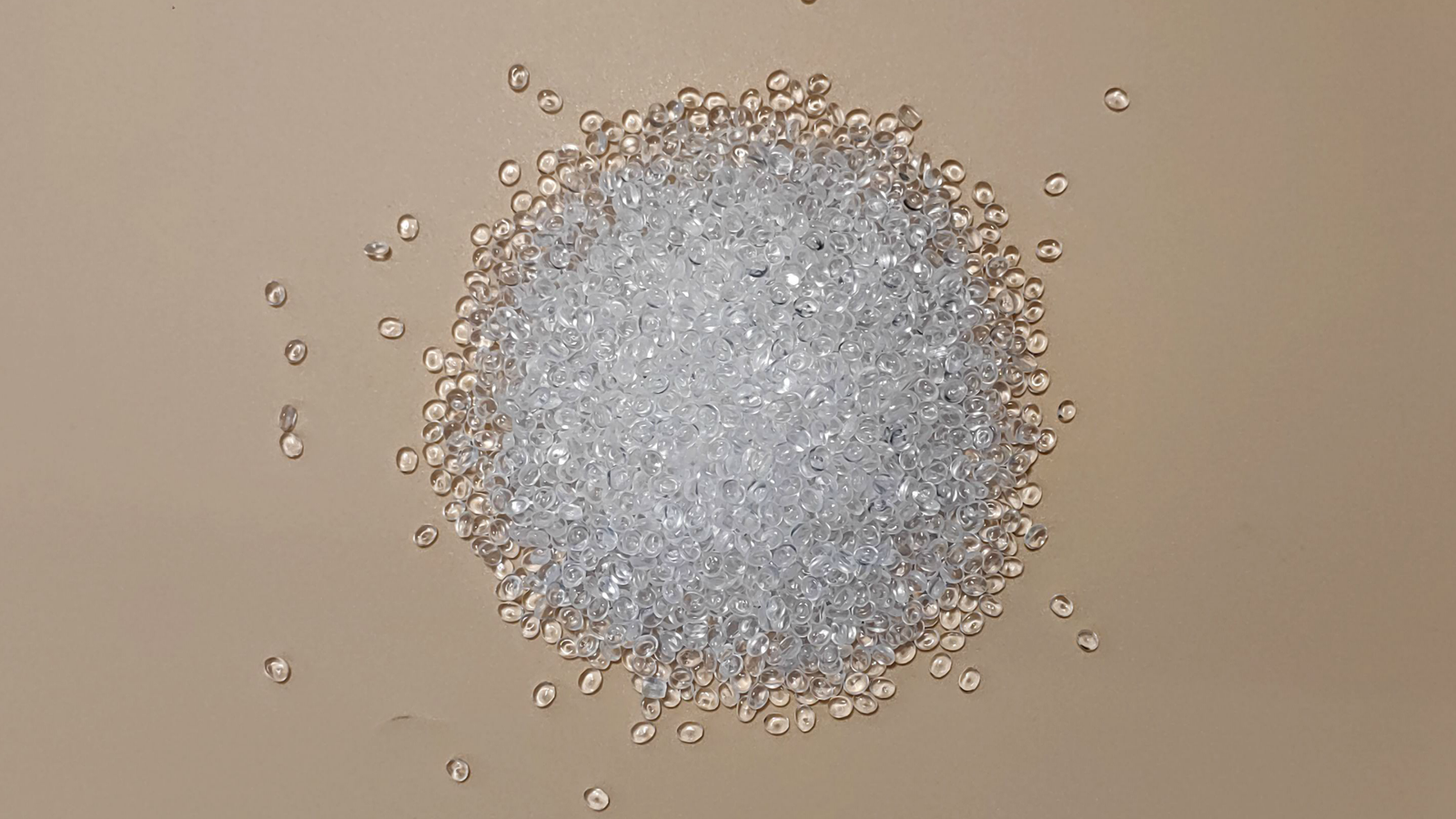

Exhibición de polietileno lineal de baja densidad de metaloceno

Explora los beneficios de nuestro material: ¡contáctanos para obtener más información!

【Recomendaciones relacionadas】

mLLDPE HP1018BM: mLLDPE resistente a altos impactos para aplicaciones de embalaje y películas Más información>

mLLDPE PF1315AZ: Resina base flexible y duradera para envases y revestimientos flexibles Más información>

mLLDPE 8784MK: mLLDPE de alta tenacidad para películas de barrera y envasado de líquidos Más información>