PRODUCTS

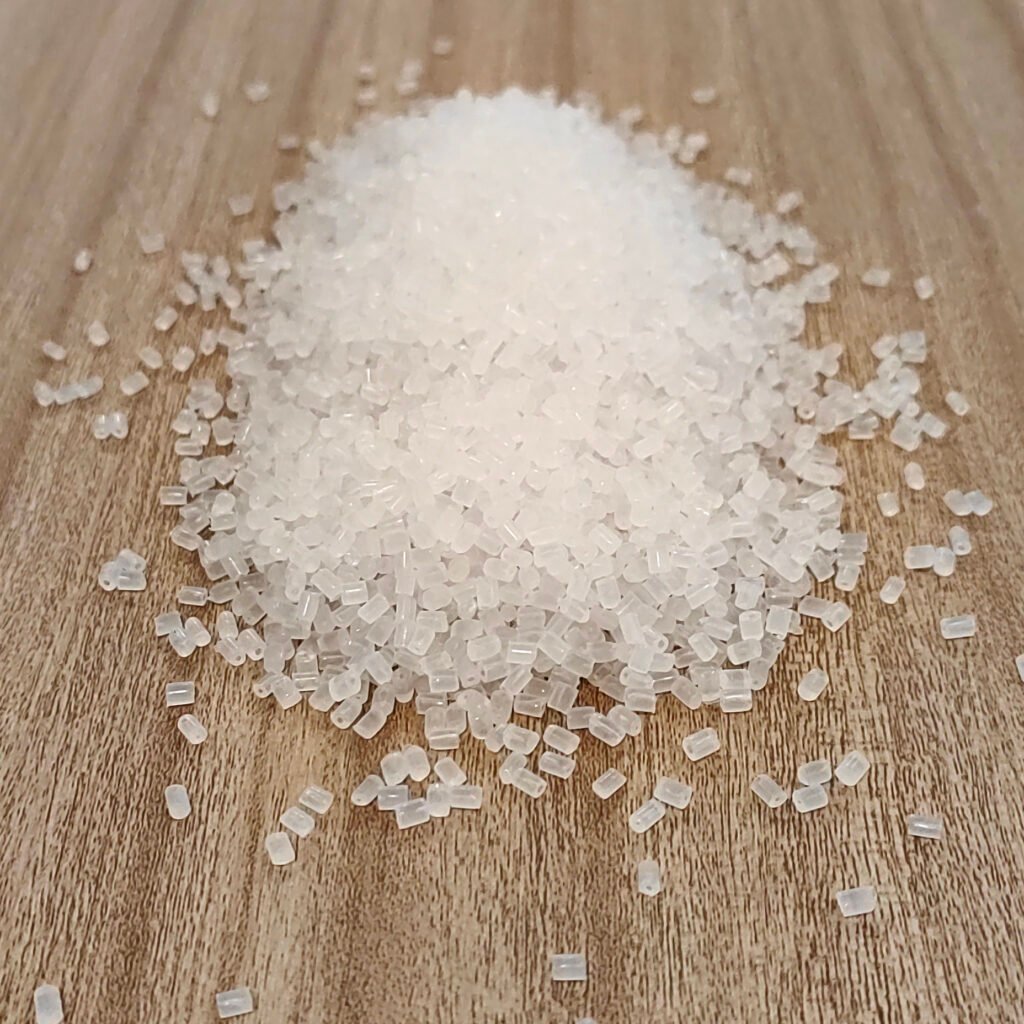

PP L-670M: High performance plastic particles

Product Struction

PP L-670M is a polypropylene random copolymer known for its excellent processability, low heat sealing temperature, and strong bonding strength. It is ideal for food packaging and widely used in BOPP film and high-quality coating applications, meeting diverse industry needs.

Material Properties

PP L-670M is a granular material with high rigidity and excellent pigment dispersion, making it suitable for various extrusion and coating processes. Its low heat sealing temperature ensures strong seals, while its high gloss and clarity enhance the appearance of packaging. Additionally, the material is virtually odorless, making it perfect for food packaging.

Applications

PP L-670M is commonly used in food packaging, BOPP film production, and extrusion coating. It offers stable sealing performance to preserve product freshness and provides ideal transparency and strength for BOPP films. Its excellent adhesion and appearance quality make it well-suited for high-end packaging applications.

| Mechanical behavior | Condition | Standard | Value | Unit | |

| Elongation | Break | ASTM D638 | 500 | % | |

| Flexural Modulus | ASTM D790 | 833.33 | MPa | ||

| Izod Notch Impact | 23°C | ASTM D256 | 5 | kJ/m² | |

| Tensile Strength | Yield | ASTM D638 | 22.54 | MPa | |

| Thermal | Condition | Standard | Value | Unit | |

| HDT | 0.45MPa | ASTM D648 | 85 | °C | |

| Melting Temperature | INTERNAL METHOD | 145 | °C | ||

| Vicat Softening Temperature | ASTM D1525 | 128 | °C | ||

| Physical property | Condition | Standard | Value | Unit | |

| Density | ASTM D792 | 0.9 | g/cm³ | ||

| Melt Index | ASTM D1238 | 28 | g/10min | ||

| Hardness | Condition | Standard | Value | Unit | |

| Rockwell Hardness | R(Scale) | ASTM D785 | 80 | ||