PRODUCTS

PP L-670M Raw Material Features Applications and Data Sheet

Product Struction

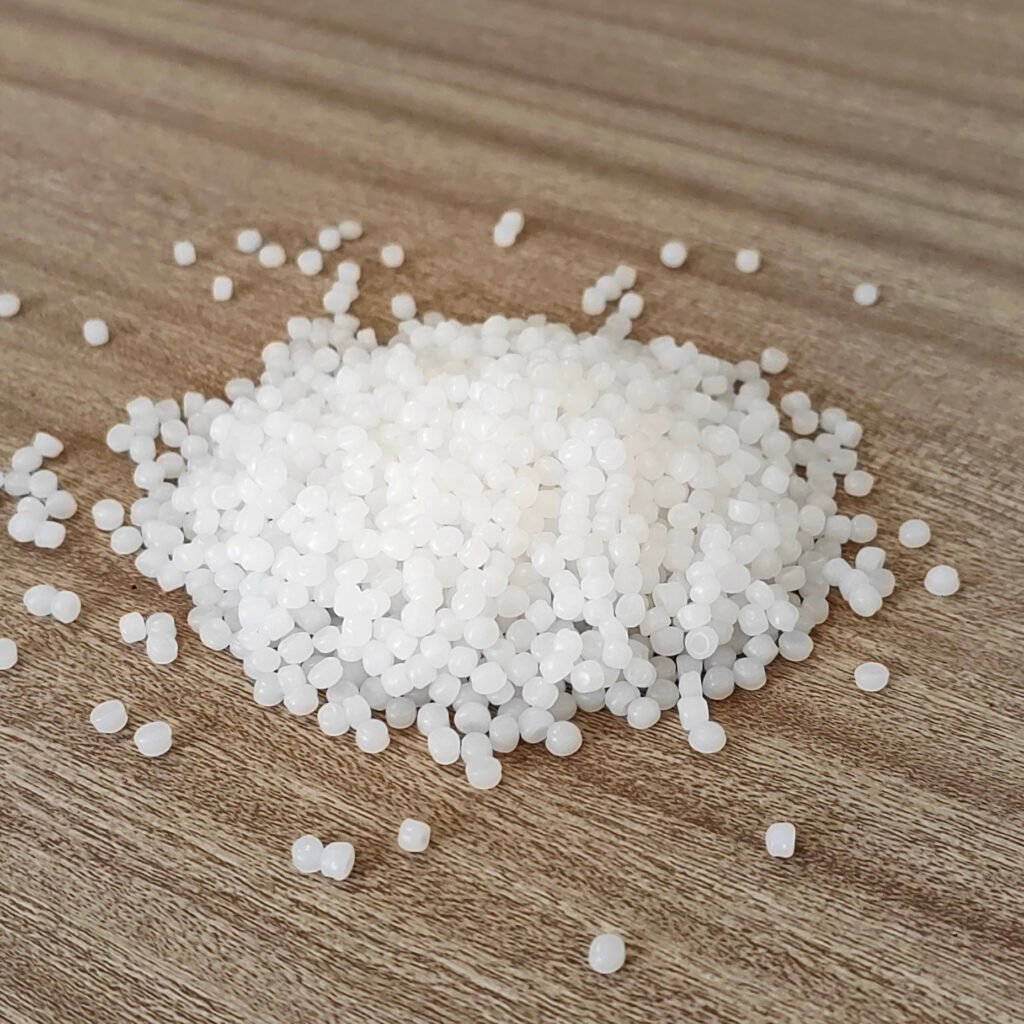

What is PP L-670M Raw Material?

PP L-670M raw material are a random copolymer polypropylene designed for extrusion molding and coating. It features high rigidity, strong bonding, excellent pigment dispersion, and superior processability, making it suitable for various industrial uses.

With high rigidity, PP L-670M ensures structural stability for demanding applications. Its strong bonding enhances adhesion to other materials or coatings, improving durability. The PP raw material’s excellent pigment dispersion ensures even color distribution, resulting in consistent, high-quality finishes.

PP L-670M excels in extrusion and coating processes, boosting efficiency and precision. It is highly compatible with pigments, delivering vibrant, long-lasting colors.

Widely used in food packaging, particularly for BOPP films, PP L-670M raw material offers transparency, mechanical strength, and moisture resistance, extending product shelf life. It also performs well in extrusion coatings, providing both protection and aesthetic appeal.

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell | Hardness R(Scale) | ASTM D785 | 80 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break | ASTM D638 | 500 | % | |||

| Flexural | Modulus | ASTM D790 | 8500 | kg/cm² | |||

| Izod | Notch Impact 23°C | ASTM D256 | 5.0 | kg-cm/cm | |||

| Tensile | Strength Yield | ASTM D638 | 230 | kg/cm² | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 0.9 | g/cm³ | ||||

| Melt | Index | ASTM D1238 | 28 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ASTM D648 | 85 | °C | |||

| Melting | Temperature | INTERNAL METHOD | 145 | °C | |||

| Vicat | Softening Temperature | ASTM D1525 | 128 | °C | |||

Click here to download TDS for PP L-670M raw material

【Related Recommendations】

PP S1003 Plastic Resin:High Rigidity & Food Contact Grade for Packaging Learn more>

PP B8101 granules:Pipe Grade Polypropylene with Excellent Heat Learn more>

PP M800E resn:High-Gloss Polypropylene for Food Packaging Learn more>