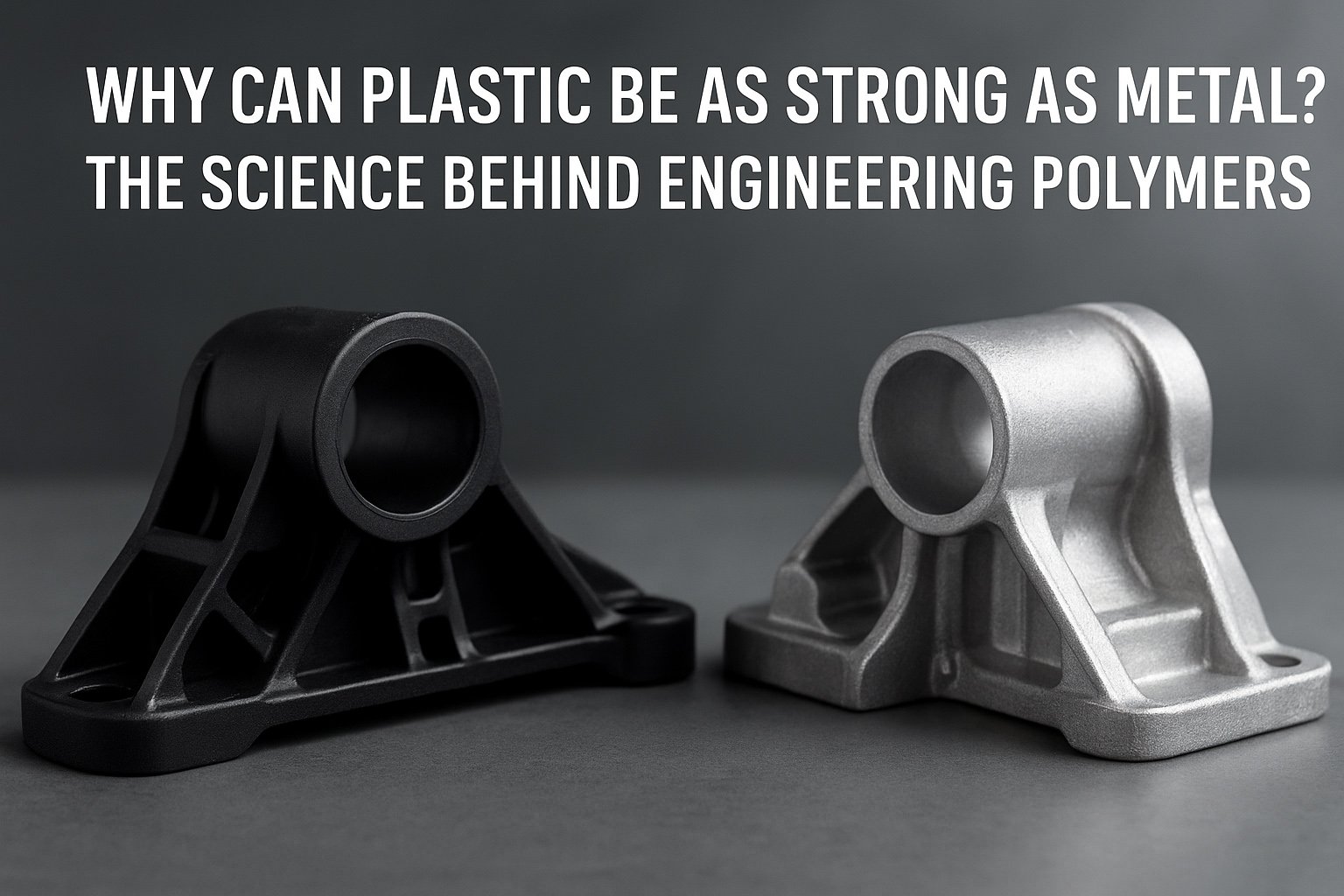

Why Can Plastic Be as Strong as Metal? The Science Behind Engineering Polymers

2025-11-03I. From "Cheap Materials" to "High-performance Materials" : The Comeback of Plastic In the public's impression, "plastic" implies being thin, fragile and not durable.However, in modern manufacturing, this concept has long been outdated.Today's Engineering Plastics can rival or even surpass some metals in terms of strength, toughness and heat resistance, and are widely used in high-demand fields such as automobiles,...

Is Plastic Harmful to the Environment? The Scientific Truth Behind a Misunderstood Material

2025-10-31I. The First Truth: Plastic is Indeed "Harmful," But Not the Whole Story From a scientific perspective, the harm caused by plastic is objectively real.Its behavior in the natural environment—especially its persistence after disposal—has become a global ecological challenge: ・Approximately 11 million tons of plastic enter the ocean annually; ・Over 90% of plastic waste is not fully recycled; ・Microplast...

Top 5 Most Watched Plastic Raw Material Trends in 2026

2025-10-30With the recovery of global manufacturing, supply chain restructuring, and the accelerated expansion of the new energy industry, the plastic raw material market is ushering in structural opportunities.For international buyers, which materials will become market "hotspots" in 2026? Which categories are worth locking in inventory for in advance?Based on international data, customer purchasing feedback, and the dynamics of major...

Refrigerator Plastics Guide: Performance, Cost & Supply

2025-10-28In the home appliance industry chain, the manufacturing of plastic parts for refrigerators is an underestimated "systematic project".From the exterior panel to the internal sliding box, from the shelf support to the bottom structure, every plastic component directly affects the overall quality, energy consumption performance and service life of the entire machine.For injection molded parts manufacturers, how to strike a balan...

PET vs PETG: Performance Comparison and Application Guide

2025-10-271. PET vs. PETG: The Essential Differences Between Two Common Polyester Plastics Among the polyester plastic family, PET (polyethylene terephthalate) and PETG (copolymer-modified PET) are two extremely versatile materials. Despite their similar names, structural differences determine their distinct processing methods, performance, and applications. 2. Structural and Morphological Differences C...

PA6 vs POM: Plastic Comparison & Selection Guide | Juyuan

2025-10-24I. Introduction In the world of engineering plastics, PA6 (nylon 6) and POM (polyoxymethylene) often appear in the same design list. Both possess excellent mechanical properties and processing adaptability, making them popular choices for mechanical parts, automotive components and precision gears. However, due to the different performance emphases, engineers often find themselves in a dilemma when making a selection: Shou...

Understanding Plastic Bottle Bottom Labels: The True Meaning Behind the Triangle Arrow Numbers

2025-10-231. Why Do Plastic Bottles Have a "Triangle, Arrow, and Number" Logo on Their Bottom? When you pick up a bottle of mineral water, shampoo or detergent and turn it over at the bottom, you can see a triangle composed of three arrows, with numbers or letters printed inside. This is not decoration but the internationally recognized Resin Identification Code (RIC).The RIC coding was first established by the American Plastic...

A Single Pellet Can Change Your Bottle Cap Factory’s Profit Margin

2025-10-211. The Upgrade Logic of the Bottle Cap Industry: From "Being Able to Make" to "Making It Well" The bottle cap, though seemingly a small component, is a critical link in the entire packaging system.It not only determines sealing, pressure resistance, and appearance, but also impacts filling line efficiency, transportation stability, and consumer experience.After 2025, the bottle cap industry is undergoing three majo...

Plastic Raw Material Pellets: Import Substitution vs. International Brand Resins — Which Offers Better Cost-Performance?

2025-10-20Against the backdrop of the accelerated transformation of the global manufacturing industry, the plastic raw material market is undergoing a "reconstruction of price/performance."On the one hand, international brand materials have long dominated, thanks to their high stability and global recognition. On the other hand, domestic and local brands of import-substituting materials are on the rise, gradually gaining market share thank...