สินค้า

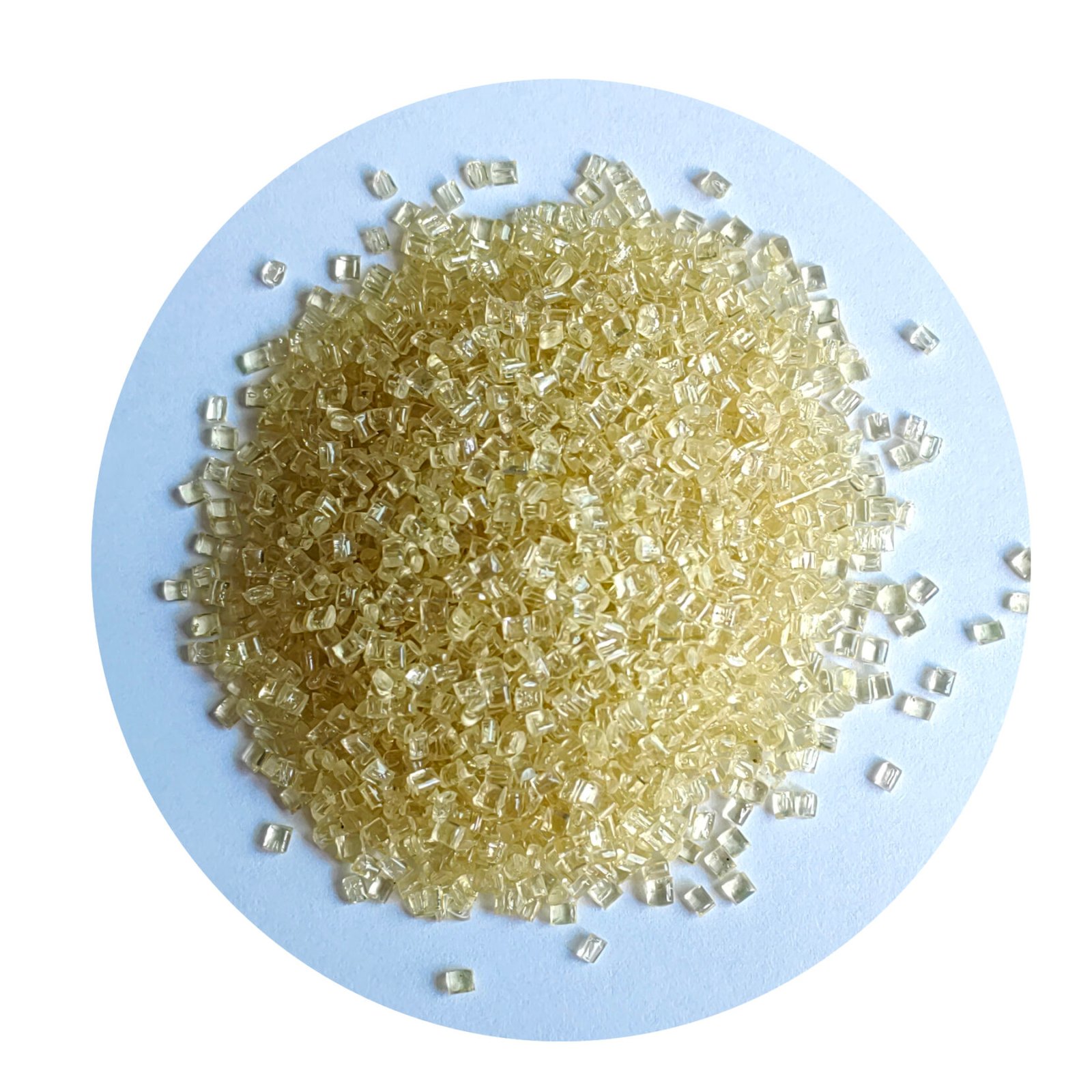

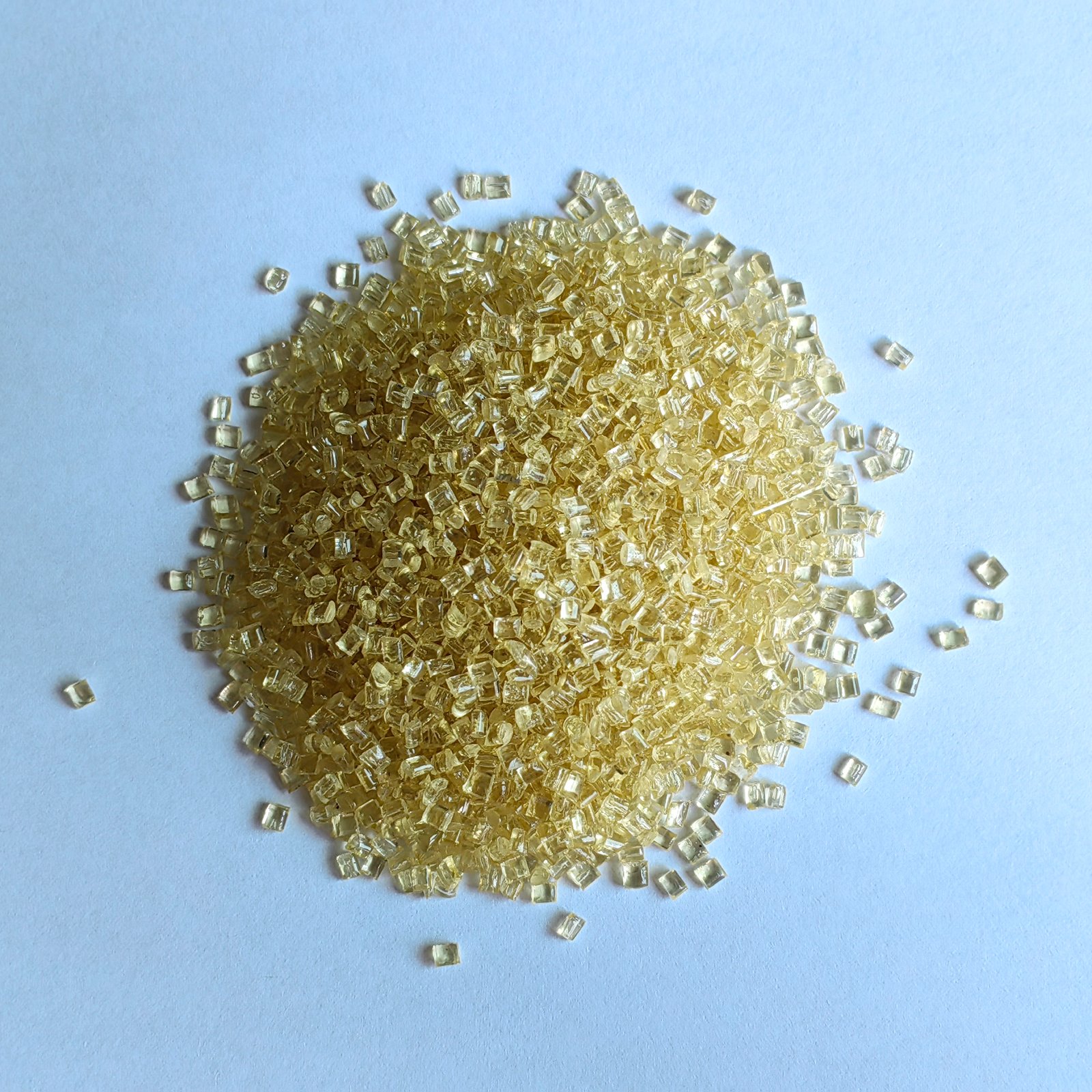

Ultrason P 3010 BASF PPSU | Baby Bottles & Medical Grade

โครงสร้างผลิตภัณฑ์

What is Ultrason P 3010

In the field of engineering plastics, polyphenylsulfone (PPSU) is widely used in medical, food contact and industrial fields due to its properties such as flame retardancy, high-temperature resistance, chemical corrosion resistance and stable mechanical strength. Ultrason P 3010 is a PPSU injection molding grade material launched by BASF. With its high-viscosity formula and outstanding comprehensive performance, it has become an ideal raw material for the manufacturing of infant products, medical devices and high-end consumer goods.

01 | Material highlights and characteristics

High-viscosity design: Suitable for complex injection molded products, with both fluidity and toughness.

Outstanding flame retardancy: Complies with UL94 V-0 grade, ensuring the product can be used in high-safety standard environments.

ความทนทานต่อสารเคมี: Suitable for harsh usage scenarios such as disinfectants and cleaning agents, and not prone to aging.

Strong thermal stability: The heat distortion temperature is close to 200°C, and it can withstand repeated high-temperature sterilization.

Excellent impact strength: It maintains good toughness at low temperatures, reducing the risk of brittle cracking.

ความปลอดภัยในการสัมผัสอาหาร: Complies with relevant regulations and is applicable to infant bottles, tableware, etc.

02 | Typical application fields

Infant and toddler care: baby bottles, drinking cups, anti-overflow caps, etc., taking into account both safety and durability.

Medical devices: Surgical instrument handles, disinfection containers, meeting the requirements of high-temperature and high-pressure sterilization.

Consumer electronics: Transparent components for high-end home appliances, which are both aesthetically pleasing and durable.

Industrial components: Parts that require chemical resistance and electrical insulation.

03 | Ultrason P 3010 Data Sheet

| คุณสมบัติทางไฟฟ้า | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ซีทีไอ | มอก.60112 | 150 | วี | ||||

| อิเล็กทริก | ความแข็งแกร่ง | ไออีซี 60243 | 44 | เควี/มม | |||

| อิเล็กทริก | คงที่ 100Hz | มอก.60250 | 3.80 | ||||

| อิเล็กทริก | คงที่ 1MHz | มอก.60250 | 3.70 | ||||

| การกระจายตัว | ปัจจัย 100Hz | มอก.60250 | 0.0017 | ||||

| การกระจายตัว | ปัจจัย 1MHz | มอก.60250 | 0.0089 | ||||

| พื้นผิว | ความต้านทาน | ไออีซี 60093 | 1E+15 | โอห์ม | |||

| ปริมาณ | ความต้านทาน | ไออีซี 60093 | 1E+15 | Ω.ซม | |||

| ความไวไฟ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| เปลวไฟ | คะแนน ทุกสี 1.5มม | UL94 | วี-0 | ||||

| เปลวไฟ | เรตติ้ง ทุกสี 3.0มม | UL94 | วี-0 | ||||

| ความแข็ง | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ลูกบอล | Indentation Hardness | ISO2039 | 124 | MPa | |||

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ชาร์ปี | รอยบากกระแทก -30°C | ISO179 | 25 | กิโลจูล/ตรม | |||

| ชาร์ปี | แรงกระแทก 23°C | ISO179 | 75 | กิโลจูล/ตรม | |||

| ชาร์ปี | ผลกระทบที่ไม่เกิดรอยบาก -30°C | ISO179 | หมายเหตุ | กิโลจูล/ตรม | |||

| ชาร์ปี | ผลกระทบที่ไม่เกิดรอยบาก 23°C | ISO179 | หมายเหตุ | กิโลจูล/ตรม | |||

| การยืดตัว | ผลผลิต 23°C | ISO 527 | 7.8 | % | |||

| ไอซอด | แรงกระแทก -30°C | ISO180 | 25 | กิโลจูล/ตรม | |||

| ไอซอด | แรงกระแทก 23°C | ISO180 | 55 | กิโลจูล/ตรม | |||

| แรงดึง | โมดูลัส 23°C | ISO 527 | 2270 | MPa | |||

| แรงดึง | ความแข็งแรง ผลผลิต 23°C | ISO 527 | 74.0 | MPa | |||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ความหนาแน่น | ISO1183 | 1.29 | กรัม/ซม.³ | ||||

| ละลาย | ดัชนี 360°C 10กก. | ISO 1133 | 35 | cm³/10นาที | |||

| การหดตัว | xFlow | ISO294 | 1.0 | % | |||

| การหดตัว | ไหล | ISO294 | 0.90 | % | |||

| น้ำ | การดูดซึม 23°C ความอิ่มตัว | ISO62 | 1.2 | % | |||

| น้ำ | Absorption 23°C 50RH Equilibrium | ISO62 | 0.60 | % | |||

| ความร้อน | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| คลี | ไหล | 5.5E-5 | ซม./ซม./°C | ||||

| เอชดีที | ยังไม่อบอ่อน 1.8MPa | ISO75 | 198 | องศาเซลเซียส | |||

| แอล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| แอล | พิกัดเปลวไฟทั้งหมด 1.5 มม | UL94 | วี-0 | ||||

| แอล | พิกัดเปลวไฟทั้งหมด 3.0 มม | UL94 | วี-0 | ||||

04 | Technology and processing techniques

Ultrason P 3010 is mainly injection molded and has a wide processing window, making it suitable for large-scale stable production.

-The ppsu material has a low shrinkage rate and high dimensional accuracy during the injection molding process.

-The high viscosity property enhances the filling effect of complex molds.

-Compatible with multiple surface treatment processes, it is suitable for transparent or colored designs.

-Thin-walled parts can be formed through mold optimization, reducing weight and material consumption.

05 | Innovation and industry competitive advantage

Compared with traditional PC or PSU materials, Ultrason P 3010 shows significant differentiation in terms of chemical resistance, thermal stability and flame retardancy:

-It offers higher long-term safety in food contact and medical-grade applications.

-In high-temperature environments, it maintains stable mechanical properties and reduces cracking and deformation of the products.

-In the context of increasingly strict regulations, it has become a reliable solution for enterprises to pursue compliance and innovation.

06 | Customer feedback

Feedback from medical and infant product manufacturers indicates:

-The baby bottles produced with Ultrason P 3010 maintain good transparency and toughness after repeated high-temperature disinfection.

-Medical customers have pointed out that it is significantly superior to conventional materials in terms of resistance to chemical corrosion, thus extending the service life of the products.

-Consumer goods customers generally recognize the advantages of this material in design flexibility and processing stability.

07 | FAQ

Q1: Is Ultrason P 3010 suitable for long-term food contact?

A1: Yes, the material meets relevant food contact safety standards and is suitable for products such as baby bottles and tableware.

Q2: Will it deform in high-temperature environments?

A2: This material has a heat deflection temperature approaching 200°C and can withstand repeated steam sterilization and high-temperature applications.

Q3: Can it replace PC?

A3: Ultrason P 3010 offers advantages over PC in terms of chemical resistance and flame retardancy, making it suitable for applications requiring higher safety and longevity.

08 | Similar recommendations

| ผู้ผลิต | Product Name | รุ่นสินค้า | Value Summary | คำอธิบาย | ความหนาแน่น | Melt Flow Index | Unit Price (Negotiable) |

| BASF | กปปส | 3010 MR WS 20264 | Viscosity: High ViscosityFlame Retardant Grade: V-0Notched Impact: 55 kJ/m² | Material Properties: Unreinforced | 1.29 g/cm³ | 80 cm³/10min | 200 RMB |

| BASF | กปปส | 3010 MR SW 10101 | Viscosity: High ViscosityFlame Retardant Grade: V-0Notched Impact: 60 kJ/m² | Material Properties: Unreinforced | 1.31 g/cm³ | 35 cm³/10min | 190 RMB |

| BASF | กปปส | 3010 MR GR 30373 | Viscosity: High ViscosityFlame Retardant Grade: V-0Notched Impact: 55 kJ/m² | Material Properties: Unreinforced | 1.29 g/cm³ | 35 cm³/10min | 190 RMB |

09 | The advantages of Juyuan as an international supplier

As a company specializing in international trade of plastic raw materials, Juyuan is committed to providing customers with:

-Multi-channel stable supply: Long-term cooperation with many international first-line manufacturers ensures an adequate supply of goods.

-Professional material selection support: Based on the product requirements of customers, we recommend the best solutions.

-Global logistics network: Fast delivery, reducing supply chain uncertainty.

-Long-term partnership: Not only providing materials, but also focusing on enhancing the market competitiveness of customers

【ข้อแนะนำที่เกี่ยวข้อง】

Mitsubishi Sultron™ PPSU LSG: High-Heat, Flame-Retardant Medical R5500/XL เรียนรู้เพิ่มเติม>

HiFill® PPSU Series: Tailored Plastics for Demanding Applications เรียนรู้เพิ่มเติม>

LNP™ THERMOCOMP™ 9X10401H Filled PPSU for Medical เรียนรู้เพิ่มเติม>