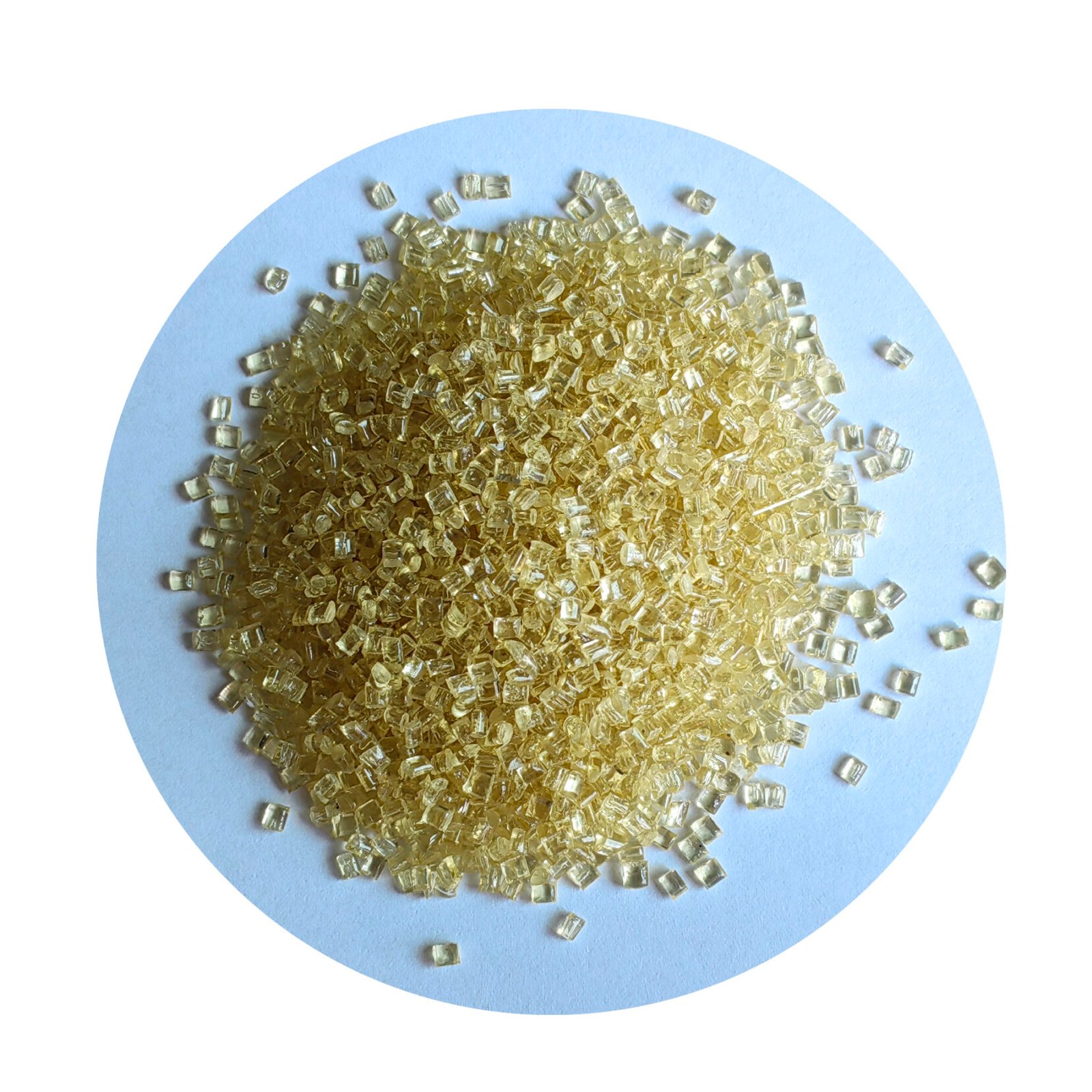

สินค้า

Udel® PSU Series Comparison & Selection

โครงสร้างผลิตภัณฑ์

1. Introduction: What are buyers most concerned about?

When selecting plastic raw materials, buyers frequently ask:

-Can this material withstand high temperatures? Is it flame-retardant certified?

-Can it be used in electrical and electronic applications? Is the molding performance good?

-Will it cause mold defects?

-Which model is best for my application?

To address these questions, this article systematically compares the Udel® PSU series, using star ratings and labels to help you quickly identify the right model.

2.Series advantages of Udel® PSU

Udel® PSU stands out in the following aspects:

・High strength: Tensile strength reaches 70.3 MPa, with strong long-term structural stability.

-High-temperature resistance: The heat distortion temperature can reach up to 174 ℃, and the melting point of some models can even reach 357 ℃.

・Flame retardant safety: Some models have passed UL94 V-0/V-1 certification.

-Dimensional stability: The shrinkage rate is only 0.7%, ensuring the formation of high-precision products.

-Toughness and durability: Excellent impact performance, with a bending strength as high as 106 MPa.

👉 These characteristics make Udel® PSU widely used in medical devices, electrical and electronic products, automotive parts, and drinking water systems.

3. Detailed Datasheet

| รุ่นสินค้า | Value Summary | คำอธิบาย | ความถ่วงจำเพาะ | Melt Flow Index | ความต้านแรงดึง | การยืดตัว | การหดตัว | อุณหภูมิการหลอมละลาย | โมดูลัสแรงดึง | Heat Distortion Temp | Izod Notched Impact | โมดูลัสแรงดัดงอ | Coefficient of Thermal Expansion | ความแข็งแรงของแรงดัดงอ |

| P-1835 | 1.24 g/cm³ | 4 g/10min | 70.3 MPa | 75% | 0.70% | - | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa | ||

| P-1800 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | - | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa | ||

| P-3703 NT 200 | 1.24 g/cm³ | 17 g/10min | 70.3 MPa | 75% | 0.70% | - | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | - | 106 MPa | ||

| P-1720 BK 935 | Flame Retardant: V-1 • V-0 | UL Compliant | 1.24 g/cm³ | 7 g/10min | 70.3 MPa | 75% | 0.70% | 357 ℃ | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa |

| P-1720 NT 13 | Flame Retardant: V-1 • V-0 | UL Compliant | 1.24 g/cm³ | 7 g/10min | 70.3 MPa | 75% | 0.70% | 357 ℃ | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa |

| P-3703 BK 937 | 1.24 g/cm³ | 17 g/10min | 70.3 MPa | 75% | 0.70% | - | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | - | 106 MPa | ||

| P-1750 NT MR | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | - | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | - | 106 MPa |

4. Udel® PSU series Performance Comparison

| แบบอย่าง | ความแข็งแกร่ง | Heat Resistance | Toughness | ระดับเปลวไฟ | Application Tags |

| P-1835 | ★★★★★ | ★★★★☆ | ★★★☆☆ | - | Medical parts / Drinking water components |

| P-1800 | ★★★★★ | ★★★★☆ | ★★★☆☆ | - | Home appliance housings / Structural parts |

| P-1750 NT MR | ★★★★★ | ★★★★☆ | ★★★☆☆ | - | General-purpose / Stable supply |

| P-3703 NT 200 | ★★★★☆ | ★★★★☆ | ★★★☆☆ | - | High flowability / Thin-wall parts |

| P-3703 BK 937 | ★★★★☆ | ★★★★☆ | ★★★☆☆ | - | Precision electronic components / Thin-wall structures |

| P-1720 BK 935 | ★★★★★ | ★★★★★ | ★★★★☆ | V-0 / V-1 | Electrical & electronic parts / Automotive electrical |

| P-1720 NT 13 | ★★★★★ | ★★★★★ | ★★★★☆ | V-0 / V-1 | High-temperature parts / Connectors |

5. Product Highlight Analysis

Udel® PSU P-1835

-Label: Strength first/Excellent stability/Medical application

-Advantage summary: Strength ★★★★★ ★; Heat resistance ★★★★☆; Toughness ★★★☆☆

-Application scenarios: Medical device shells, drinking water parts

Udel® PSU P-1800

-Label: Injection-molded general-purpose/High-strength/Home appliance shell

-Advantage summary: Strength ★★★★★ ★; Heat resistance ★★★★☆; Toughness ★★★☆☆

-Application scenarios: Home appliance casings, structural components

Udel® PSU P-1750 NT MR

-Tags: General Model/Stable Supply/High Cost Performance

-Advantage summary: Strength ★★★★★ ★; Heat resistance ★★★★☆; Toughness ★★★☆☆

-Application scenario: Structural components, suitable for purchasers who need long-term supply guarantee

Udel® PSU P-3703 series (NT 200 / BK 937)

-Labels: High fluidity/Preferred for thin-walled parts/High molding efficiency

-Advantage summary: Strength ★★★★☆; Heat resistance ★★★★☆; Toughness ★★★☆☆

-Application scenarios: Electronic components, automotive interior parts, complex molds

Udel® PSU P-1720 series (BK 935 / NT 13)

-Label: High Flame Retardancy/UL Certified/High-temperature components

-Advantage intuitive conclusion: painted painted painted painted painted strength u u | heat painted painted painted painted painted u | toughness u do | 0 flame retardant grade V/V - 1

-Application scenarios: Electrical switches, automotive electrical components, connectors

6. Summary of recommended scenarios

Medical & Drinking Water → P-1835 / P-1800

Household appliances & Structural Components → P-1800 / P-1750

Thin-walled & high-flow molding → P-3703 series

High flame retardant electronics & High-temperature environment → P-1720 series

7. Why choose the Udel® PSU provided by Juyuan?

Complete range of models → One-stop coverage of the entire series including P-1835, P-1800, P-3703, P-1720, and P-1750

Certification Assurance → Compliant with UL, drinking water, and medical-related regulations

Fast supply → Global channels, stable delivery time

Professional support → Material selection consultation + technical guidance, reducing trial-and-error costs

บทสรุป

If you are looking for engineering plastics that are high-strength, heat-resistant, flame-retardant and compliant, the Udel® PSU series will be your best choice.

Contact Juyuan immediately for a quote and the most suitable model recommendation.

【ข้อแนะนำที่เกี่ยวข้อง】

RTP Engineering Plastics Series Comparison | Juyuan เรียนรู้เพิ่มเติม>

Plastic Material Data Sheet Explained: Key Properties, Test Methods & Value Guide เรียนรู้เพิ่มเติม>

RTP 2000 Series: Flame-Retardant Plastics Comparison เรียนรู้เพิ่มเติม>