สินค้า

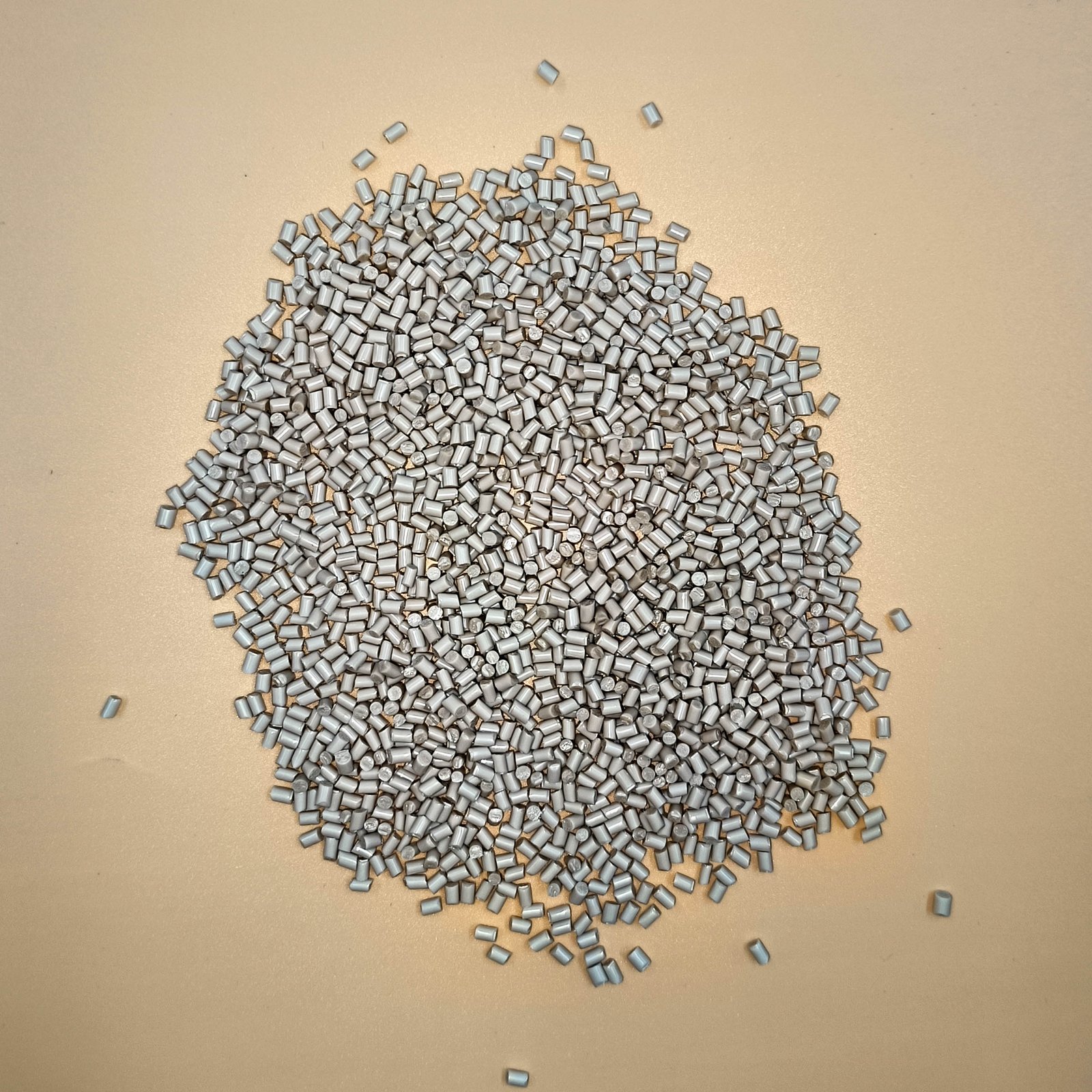

SABIC LGL33 | Plastic PEEK Material for Automotive Engine Hood

โครงสร้างผลิตภัณฑ์

What is Plastic PEEK Material

Plastic PEEK material, with its excellent heat resistance, wear resistance, and dimensional stability, is an ideal material choice for automotive hood and underhood structural components.

LNP™ LUBRICOMP™ LGL33 (PDX-L-90086), produced by SABIC, is a composite modified PEEK material (PEEK-CD15-PTFE15). By adding 15% graphite and 15% PTFE, its stability and life in high-temperature friction environments are significantly improved.

In automotive underhood systems, LGL33 can be used to replace traditional metal or unfilled PEEK components, reducing vehicle weight while improving wear resistance and noise performance, meeting the demanding operating conditions of the underhood.

01 | Material Highlights

Outstanding wear resistance

-Containing 15% graphite and 15% PTFE, the material forms a self-lubricating system internally, significantly reducing wear under repeated friction or sliding conditions.

Stable coefficient of friction

-The static friction coefficient is 0.39 and the dynamic friction coefficient is 0.36 (ASTM D3702), maintaining smooth operation in a continuous friction environment.

Good mechanical strength

-The tensile strength reaches 65 MPa, and the flexural modulus exceeds 4300 MPa. It can maintain structural integrity even after long-term use.

Excellent heat resistance

-The heat distortion temperature can reach up to 298°C (ASTM D648, 0.45MPa), and it can withstand the high-temperature environment in the engine compartment of automobiles.

Stable in size and low water absorption rate

-The water absorption rate is only 0.03%, maintaining precise fit and reliable performance even under changes in humidity.

02 | Processing and Technology Compatibility

LNP™ LUBRICOMP™ LGL33 is specifically designed for injection molding applications.

・Flow characteristic balance: The modified filler structure ensures uniform distribution of the material during the molten flow process, reducing warpage and internal stress.

・Low shrinkage rate: The shrinkage rate is 1.3% in the flow direction and 1.5% in the vertical direction, ensuring precise product dimensions.

・Suggested mold temperature: It is recommended to control it between 170 and 190°C to balance surface quality and crystallinity.

It is suitable for structural components, wear-resistant parts and moving components with extremely high requirements for dimensional accuracy.

03 | Typical Applications

Automobile hood and engine compartment components

-It has both heat resistance and wear resistance, and can replace metal parts to reduce weight and cost.

Compressor and pump body assembly

-It exhibits stable wear resistance under dry friction or boundary lubrication conditions, thereby extending the service life of equipment.

Mechanical bushings, gears, sliders

-It has excellent silent effect and low wear characteristics, making it suitable for industrial equipment that operates continuously.

04 | LNP™ LUBRICOMP™ LGL33 (PDX-L-90086) Data Sheet

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| Instrument Impact | 23°C Total Energy | เกรด ASTM D3763 | 5 | เจ | |||

| การยืดตัว | หัก 5มม./นาที | มาตรฐาน ASTM D638 | 3.9 | % | |||

| การยืดตัว | หัก 5มม./นาที | ISO 527 | 3.8 | % | |||

| Multi-Axial Impact | ตามมาตรฐาน ISO 6603 | 1 | เจ | ||||

| ความแข็งแรงของแรงดัดงอ | ISO178 | 116 | MPa | ||||

| ความแข็งแรงของแรงดัดงอ | แตกหัก 1.3มม./นาที | ASTM D790 | 119 | MPa | |||

| โมดูลัสแรงดัดงอ | 1.3มม./นาที | ASTM D790 | 4380 | MPa | |||

| โมดูลัสแรงดัดงอ | 2.0มม./นาที | ISO178 | 4240 | MPa | |||

| อิซอด อิมแพ็คอันโน๊ตช์ | 23°ซ | แอสทาม D4812 | 36.93 | กิโลจูล/ตรม | |||

| อิซอด อิมแพ็คอันโน๊ตช์ | 23°C 4.0มม. | ISO180 | 23 | กิโลจูล/ตรม | |||

| อิซอด นอทช์ อิมแพ็ค | 23°ซ | มาตรฐาน ASTM D256 | 4.48 | กิโลจูล/ตรม | |||

| อิซอด นอทช์ อิมแพ็ค | 23°C 4.0มม. | ISO180 | 4 | กิโลจูล/ตรม | |||

| ความต้านแรงดึง | หัก 5มม./นาที | มาตรฐาน ASTM D638 | 65 | MPa | |||

| ความต้านแรงดึง | หัก 5มม./นาที | ISO 527 | 65 | MPa | |||

| โมดูลัสแรงดึง | 1.0มม./นาที | ISO 527 | 4290 | MPa | |||

| โมดูลัสแรงดึง | 5mm/min | มาตรฐาน ASTM D638 | 4310 | MPa | |||

| Friction Factor | Ring | แอสทาม D3702 | 0.0 | ft-lb-hr | |||

| Friction Factor | Washer | แอสทาม D3702 | 46 | ft-lb-hr | |||

| ค่าสัมประสิทธิ์แรงเสียดทาน | สถิตย์ | แอสทาม D3702 | 0.39 | ||||

| ค่าสัมประสิทธิ์แรงเสียดทาน | พลวัต | แอสทาม D3702 | 0.36 | ||||

| ความร้อน | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| เอชดีที | 0.45เมกะปาสคาล 4.0มม | ISO75 | 247 | องศาเซลเซียส | |||

| เอชดีที | 1.8เมกะปาสคาล 4.0มม | ISO75 | 154 | องศาเซลเซียส | |||

| เอชดีที | Unannealed 0.45MPa 3.2mm | มาตรฐาน ASTM D648 | 298 | องศาเซลเซียส | |||

| เอชดีที | Unannealed 1.8MPa 3.2mm | มาตรฐาน ASTM D648 | 161 | องศาเซลเซียส | |||

| คลี | Flow -30.0~30°C | มาตรฐาน ASTM D696 | 4.1E-5 | ซม./ซม./°C | |||

| คลี | xFlow -30.0~30°C | มาตรฐาน ASTM D696 | 4.6E-5 | ซม./ซม./°C | |||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การดูดซึมน้ำ | 50RH 24hr | มาตรฐาน ASTM D570 | 0.03 | % | |||

| การดูดซึมน้ำ | 23°C 50RH | ISO62 | 0.05 | % | |||

| การหดตัว | Flow 24hr | มาตรฐาน ASTM D955 | 1.3 | % | |||

| การหดตัว | xFlow 24hr | มาตรฐาน ASTM D955 | 1.5 | % | |||

| ความหนาแน่น | ASTM D792 | 1.46 | กรัม/ซม.³ | ||||

05 | Industry Trends

Plastic PEEK material leads the lightweighting of automotive engine hoods

With the increasing demand for automotive lightweighting and durability, plastic PEEK material containing graphite and PTFE is being widely used in engine hood and engine compartment structural components.

This type of composite material can reduce weight by more than 40% compared to aluminum alloy and has better heat resistance and wear resistance, making it suitable for high-temperature and high-friction working environments.

In new energy vehicle models, the insulation and chemical stability of PEEK have also become important factors in ensuring system safety.

As a professional supplier of plastic raw materials, Juyuan can provide multiple brands of modified PEEK particles and support formula fine-tuning and technology selection, helping customers achieve a balance between performance and cost in engine hood projects.

06 | Similar Recommendations

To meet the varying performance requirements of automotive hood and engine compartment systems, Juyuan recommends the following similar materials as alternatives or complementary options:

| รุ่นสินค้า | คำอธิบาย | ความถ่วงจำเพาะ | ความต้านแรงดึง | การยืดตัว | การหดตัว | โมดูลัสแรงดึง | อุณหภูมิการเบี่ยงเบนความร้อน | Izod Notched Impact | โมดูลัสแรงดัดงอ | Izod Unnotched Impact | Coefficient of Linear Expansion | ความแข็งแรงของแรงดัดงอ | Property Summary |

| LL003 (LL-4030) | Application: Automotive engine covers • Oil/Natural gas applications | 1.39 g/cm³ | 64 MPa | 4.50% | 0.9–2% | 3000 MPa | 156 ℃ | 48 J/m | 2940 MPa | 723 J/m | 4.7E-5 cm/cm/℃ | 92 MPa | Notched impact: 4.89 kJ/m²Heat deflection temperature: 156 ℃ |

| LF003 (LF-1003) | Application: Automotive engine covers | 1.39 g/cm³ | 136 MPa | 2.90% | 0.80% | 74460 MPa | 328 ℃ | 53 J/m | 62740 MPa | 854 J/m | 4.86E-5 cm/cm/℃ | 199 MPa | Notched impact: 5.40 kJ/m²Heat deflection temperature: 328 ℃ |

| LCL33E (LCL-4033 EM) | Material Characteristics: Easy to moldApplications: Oil/Natural gas • Aircraft interiors • Automotive engine covers • Electrical & electronic components | 1.43 g/cm³ | 179 MPa | 1.70% | 0.1–0.3% | 16610 MPa | 298 ℃ | 64 J/m | 12960 MPa | 491 J/m | 2.37E-5 cm/cm/℃ | 266 MPa | Flammability rating: V-0Notched impact: 6.53 kJ/m² |

These materials can be flexibly combined based on product requirements and usage environments.

07 | Frequently Asked Questions (FAQ)

Q1: What are the differences between PEEK filled with graphite /PTFE and pure PEEK?

A1: Composite fillers significantly reduce the coefficient of friction and enhance the wear-resistant service life, making them particularly suitable for long-term sliding or rotating components.

Q2: Can LNP™ LGL33 replace metal parts?

A2: It is fully feasible in mechanical or automotive parts with medium and low loads, which can reduce weight and improve lubrication performance.

Q3: Are there any appearance restrictions on this material?

A3: Due to the presence of PTFE, the surface is slightly matte and is not suitable for occasions where a transparent or high-gloss appearance is required.

08 | Reasons to Choose Juyuan

As an international supplier with 24 years of experience in plastic raw material trading and blending, Juyuan offers customers:

・Multi-channel stable supply system: Maintaining long-term cooperation with multiple brands and authorized distributors, and possessing independent modification and repackaging capabilities, it can flexibly meet the demands of different projects.

・Technical and processing support: Based on the customer's injection molding, extrusion or modification processes, provide formula matching and processing parameter suggestions;

・Global trade and logistics advantages: A complete international transportation and inventory management system ensures efficient and continuous supply of raw materials.

Whether you are developing automotive precision parts, industrial wear-resistant parts or special engineering plastic applications, Juyuan can provide you with stable and reliable plastic PEEK material procurement and technical support solutions.

【ข้อแนะนำที่เกี่ยวข้อง】

Lubrizol PEEK A-1440 CNT Reinforced Conductive PEEK Pellets เรียนรู้เพิ่มเติม>

Lubrizol Carbo-Rite™ A-1441: Corrosion-Resistant PEEK Granules เรียนรู้เพิ่มเติม>

High Impact Plastic | Engineering Material Guide for Buyers เรียนรู้เพิ่มเติม>