สินค้า

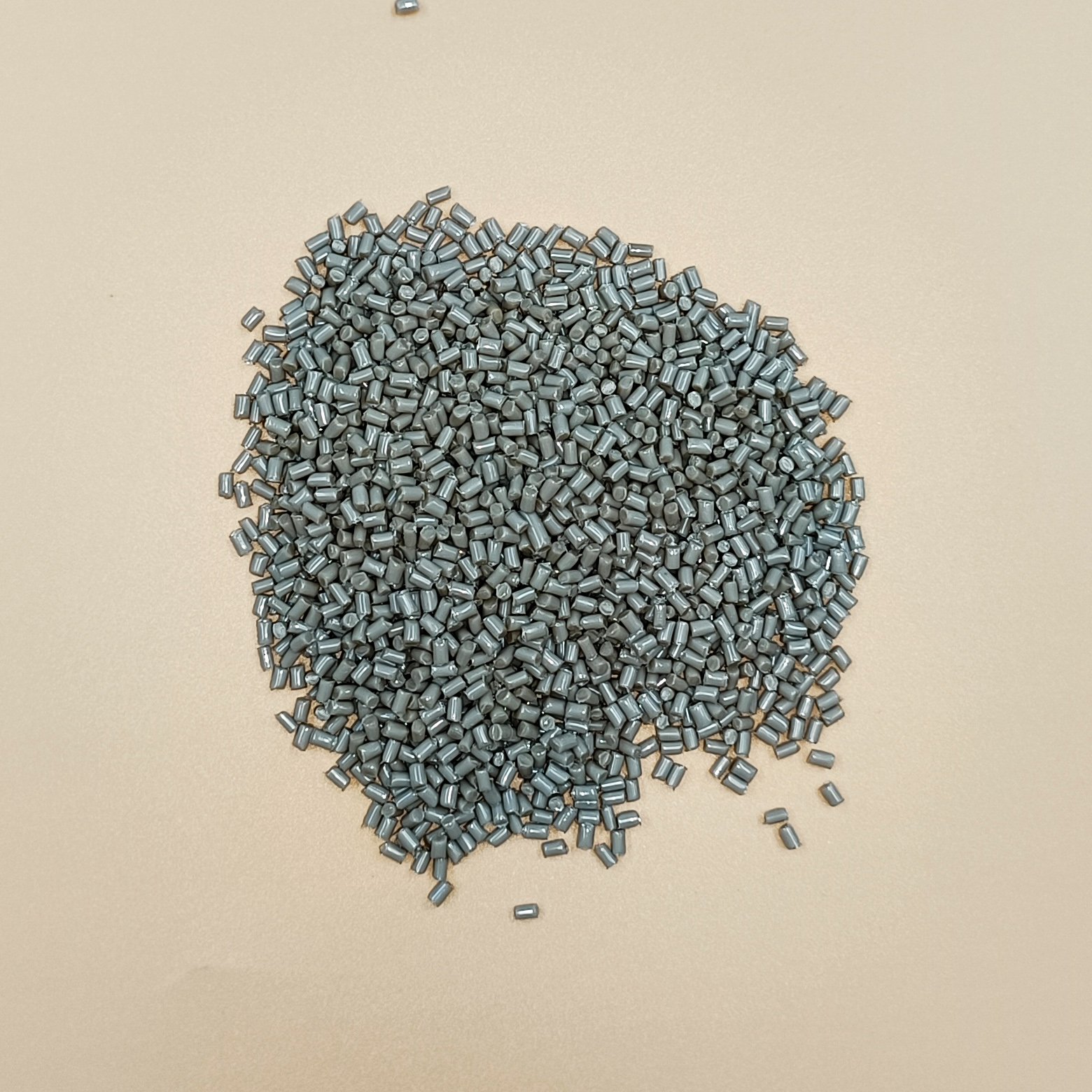

PEEK 450 CF30 Black 9579 Polyetheretherketone Material

โครงสร้างผลิตภัณฑ์

What is Polyetheretherketone Material

PEEK 450 CF30 black 9579 is a carbon fiber reinforced polyetheretherketone material developed by Ensinger of Germany. This material, with precision engineering and adaptation to extreme environments at its core, combines the inherent thermal stability of PEEK with the rigidity of carbon fiber, enabling it to demonstrate outstanding performance stability in structural components, load-bearing parts, and high-friction environments.

01 | Material Highlights and Characteristics

Carbon fiber enhances structural strength

-The approximately 30% carbon fiber content significantly enhances tensile strength and modulus, enabling the polyetheretherketone material to maintain dimensional stability and mechanical integrity even under high loads.

Excellent heat resistance

-It can be used for a long time at 260°C and can withstand short-term temperatures up to 300°C, meeting the extreme working conditions of automotive engine compartments, thermal mechanical devices and electronic insulation components.

Dimensional stability and low shrinkage rate

-After molding, the deformation rate is extremely low, making it suitable for high-precision assemblies and complex-shaped components.

Good wear resistance and self-lubricating performance

-The carbon fiber network forms a stable friction interface on the surface, reducing the wear rate and extending the service life of the parts.

Black appearance and high surface texture

-It provides visual uniformity and anti-pollution performance in industrial equipment or appearance parts, and is widely used in high-end commercial equipment.

02 | ฟิลด์การใช้งานทั่วไป

・Automotive industry: High-temperature load-bearing components such as engine compartment brackets, clutch assemblies, oil pump parts, and turbine spacer rings.

・Mechanical engineering: Wear-resistant sliding rings, gears, bearing housings, sealing rings, etc.

・Electronic and commercial equipment: Printer rails, connector housings, electrostatic sensitive parts.

・Precision instrument engineering: Structural components requiring high rigidity and thermal stability in aviation and medical machinery.

This polyetheretherketone material performs particularly well in engineering applications that require extremely high dimensional accuracy due to its high specific modulus and extremely low coefficient of thermal expansion.

03 | PEEK 450 CF30 black 9579 Data Sheet

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การยืดตัว | เบรก 50มม./นาที | ISO 527 | 1.5 | % | |||

| ความต้านแรงดึง | 50มม./นาที | ISO 527 | 220 | MPa | |||

| โมดูลัสแรงดึง | 50มม./นาที | ISO 527 | 22500 | MPa | |||

| ชาร์ปี้ อิมแพ็คแบบไร้รอยบาก | ISO179 | 33 | กิโลจูล/ตรม | ||||

| ความร้อน | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| Operating temperature | Short Time | วิธีการภายใน | 300 | องศาเซลเซียส | |||

| Operating temperature | Long Time | วิธีการภายใน | 260 | องศาเซลเซียส | |||

| เอชดีที | 1.8MPa | ISO75 | 326 | องศาเซลเซียส | |||

| อุณหภูมิการหลอมละลาย | DIN 53765 | 343 | องศาเซลเซียส | ||||

| อุณหภูมิเปลี่ยนผ่านของแก้ว | DIN 53765 | 143 | องศาเซลเซียส | ||||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| Bulk density | ไอเอสโอ 60 | 0.63 | กรัม/ซม.³ | ||||

| การหดตัว | ไหล | ISO294 | 0.31 | % | |||

| การหดตัว | xFlow | ISO294 | 0.89 | % | |||

| ความหนาแน่น | วิธีการภายใน | 1.44 | กรัม/ซม.³ | ||||

| ดัชนีการหลอมละลาย | 380°C 5kg | ISO 1133 | 2.5 | ก./10 นาที | |||

| ดัชนีการหลอมละลาย | 380°C 5kg | ISO 1133 | 5.5 | cm³/10นาที | |||

| คุณสมบัติทางไฟฟ้า | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ความต้านทานปริมาตร | ISO 3915 | 2.41E+4 | Ω.ซม | ||||

04 | Process Processing and Technology Adaptation

PEEK 450 CF30 black 9579 can be processed by injection molding, extrusion molding and machining, etc., and is compatible with mainstream thermoplastic process equipment.

Processing suggestions

・Drying temperature: above 150°C, ensuring the moisture content is below 0.05%.

・Melting temperature range: 370-400°C, ensuring uniform material flow and thorough fiber dispersion.

・Mold temperature control: 170-200°C to ensure crystallinity and dimensional stability.

Its excellent fluidity and stability enable processing enterprises to significantly reduce the defect rate and maintenance costs when achieving high-precision parts.

05 | Innovation and Industry Competitive Advantage

Compared with traditional glass fiber reinforced PEEK, carbon fiber reinforced polyetheretherketone material has obvious advantages in rigidity, thermal conductivity and surface resistance characteristics:

-Higher heat conduction efficiency and reduced risk of heat concentration;

-The optimized electrical parameters make it more competitive in electrostatic safety applications.

-The fatigue life of the material is prolonged, making it suitable for long-term high-frequency moving parts.

Through the composite fiber distribution control technology, Enxingge has achieved the balance of material performance in both the longitudinal and transverse directions, providing greater freedom for engineering design.

06 | Customer Feedback and Application Effectiveness

Feedback from customers in the automotive and precision machinery industries indicates:

-After replacing the metal parts with PEEK 450 CF30, the overall weight of the machine was reduced by approximately 20%, and there were no signs of structural fatigue in high-temperature vibration environments.

-The dimensional stability of this polyetheretherketone material is astonishing, especially in complex geometric parts, where almost no post-processing correction is required.

Customers generally believe that this material has significant economic and technical dual advantages in replacing metals and high-end engineering plastics.

07 | Frequently Asked Questions (FAQ)

Q1: Can PEEK 450 CF30 be used for electrical insulation?

A: Yes. Its volume resistance and carbon fiber structure have been optimized, ensuring good insulation properties even at high temperatures.

Q2: Compared with pure PEEK material, is its processing more difficult?

A: Due to the addition of carbon fiber, the fluidity is slightly lower, but stable processing can be achieved through appropriate mold temperature control and injection parameters.

Q3: Is it suitable for assembly with metal parts?

A: Yes, its coefficient of thermal expansion is close to that of some alloys and can be used in the design of composite structural components.

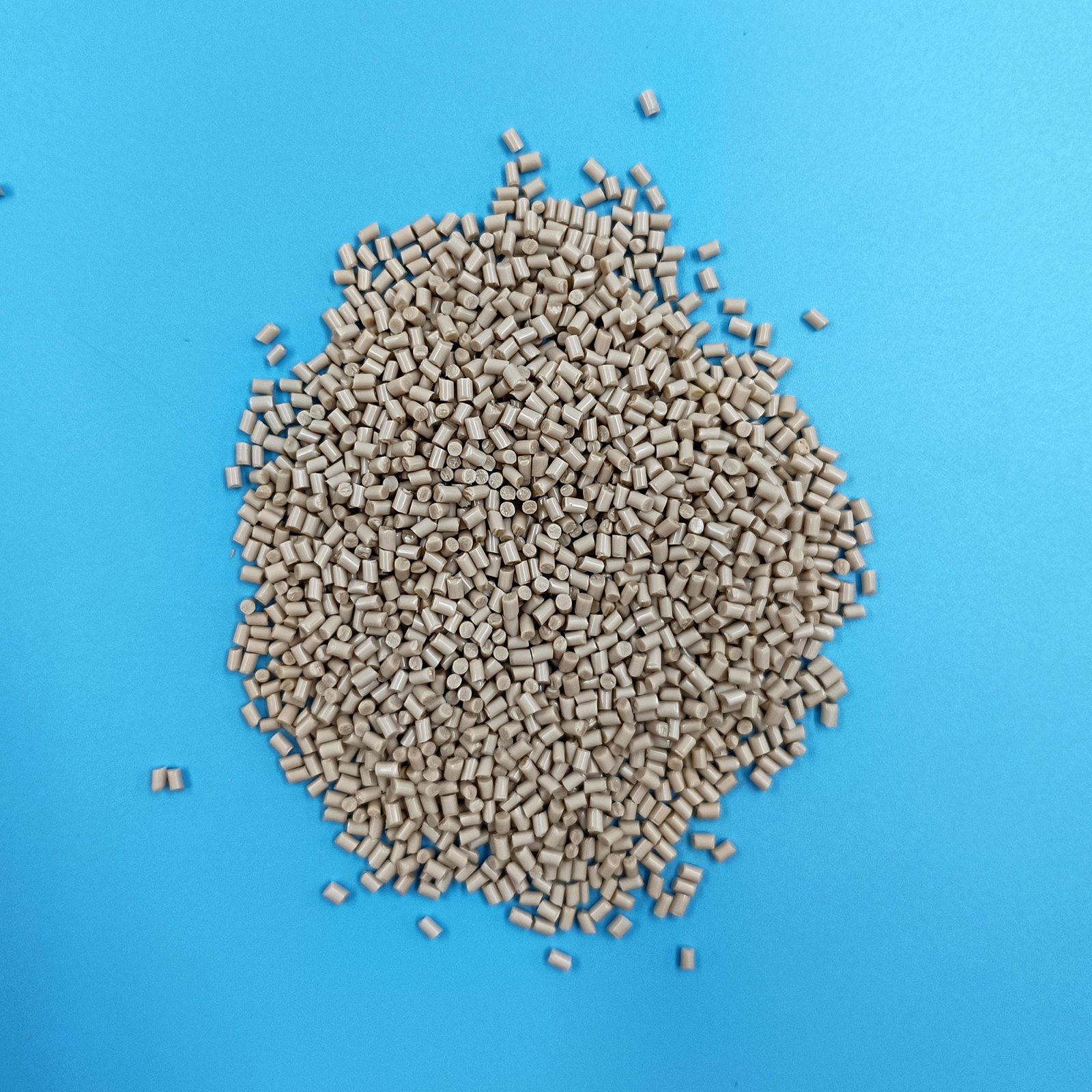

08 | Similar Recommendations

| รุ่นสินค้า | ความถ่วงจำเพาะ | ความต้านแรงดึง | การยืดตัว | โมดูลัสแรงดึง |

| PEEK 450 GF30 natural 9582 | 1.51 g/cm³ | 185 MPa | 3.0 % | 10500 MPa |

| PEEK 450 CF30 black 3198 | 1.39 g/cm³ | 190 MPa | 2 % | 17500 MPa |

| PEEK 450 GF30 black 3689 | 1.52 g/cm³ | 175 MPa | 2.5 % | 10000 MPa |

| PEEK 450 GF30 black 3583 | 1.52 g/cm³ | 105 MPa | 4 % | 7500 MPa |

| PEEK 450 GF30 brown 3606 | 1.54 g/cm³ | 90 MPa | 3.5 % | 6500 เมกะปาสคาล |

| PEEK 450 CF30 black 3642 | 1.4 g/cm³ | 240 MPa | 1.5 % | 22000 MPa |

| PEEK 450 CF30 MP black 4225 | 1.4 g/cm³ | 205 MPa | 2.5 % | 20400 MPa |

| PEEK 450 CF30 RG black 3810 | 1.39 g/cm³ | 195 MPa | 2 % | 16000 MPa |

09 | Juyuan's Advantages in Foreign Trade Supply

As an international supplier of plastic raw materials, Juyuan has been deeply engaged in the trade of engineering plastics for 24 years, focusing on the global distribution of polyetheretherketone material.

Our advantages include:

🌐 International supply chain network - covering markets in Europe, southeast Asia, the Middle East and North America.

🧪 Professional material selection guidance - provide technical matching and material comparison based on customer application requirements.

🚢 Flexible delivery and inventory management - supports small batch samples, custom batches and long-term supply contracts.

🛠 One-stop technical service - from material selection, process guidance to logistics tracking, ensuring delivery efficiency and project safety.

Juyuan is committed to enabling global customers to more easily achieve the best balance of performance, cost and supply stability when choosing polyetheretherketone material.

บทสรุป

PEEK 450 CF30 black 9579 is not only a material, but also a symbol of technological innovation.

Under the synergy of carbon fiber reinforcement and polyetheretherketone matrix, this polyetheretherketone material has become an indispensable basic material for future high-end manufacturing, automotive lightweighting and precision industry.

【ข้อแนะนำที่เกี่ยวข้อง】

Evonik PEEK DC 4430 G: Medical-grade peek granules for dental applications เรียนรู้เพิ่มเติม>

SCHULATEC® PEEK GF 30 NV 12: Glass Fiber Reinforced Virgin PEEK Material เรียนรู้เพิ่มเติม>

DOMO PEEK 3350R30: Engineered PEEK Polyetheretherketone เรียนรู้เพิ่มเติม>