สินค้า

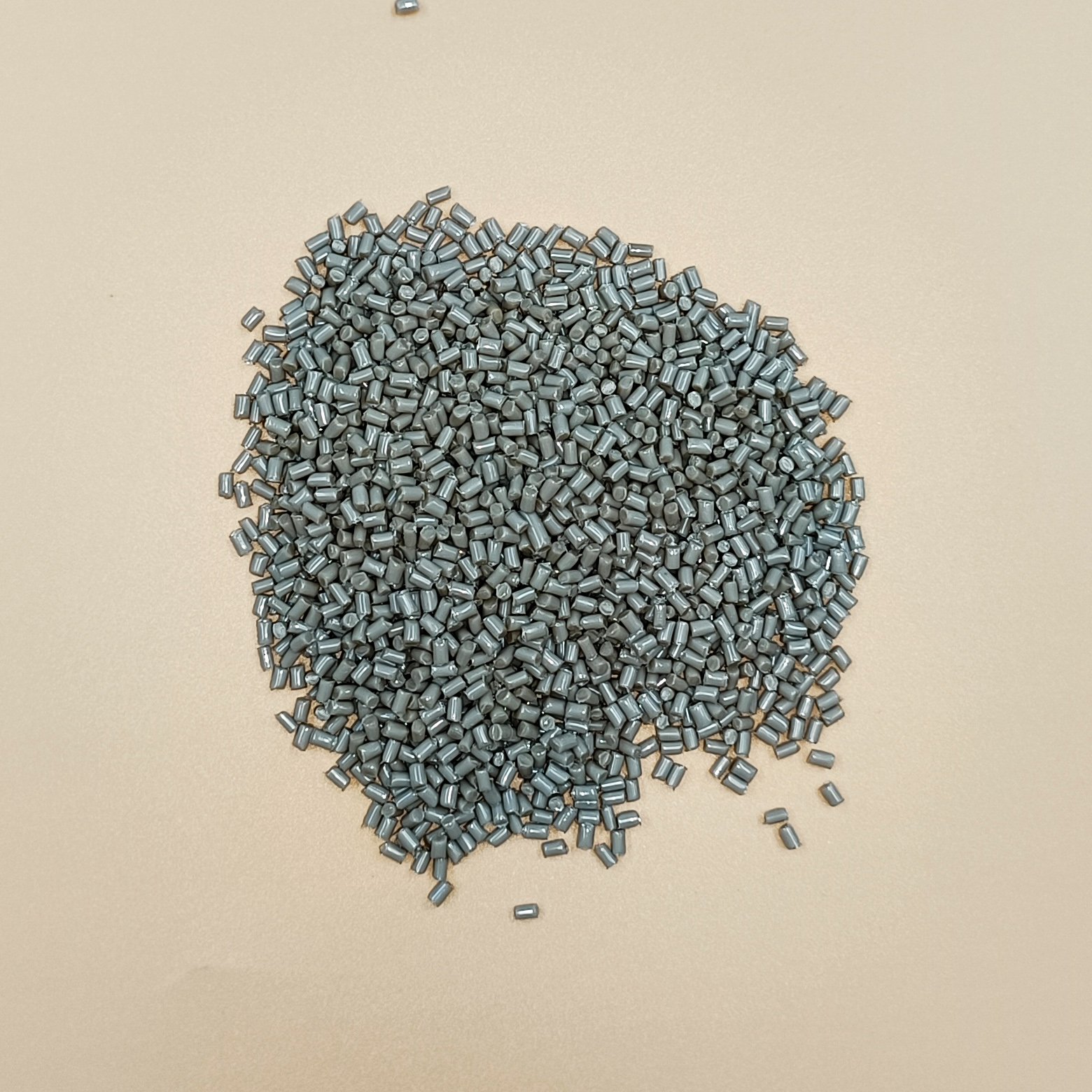

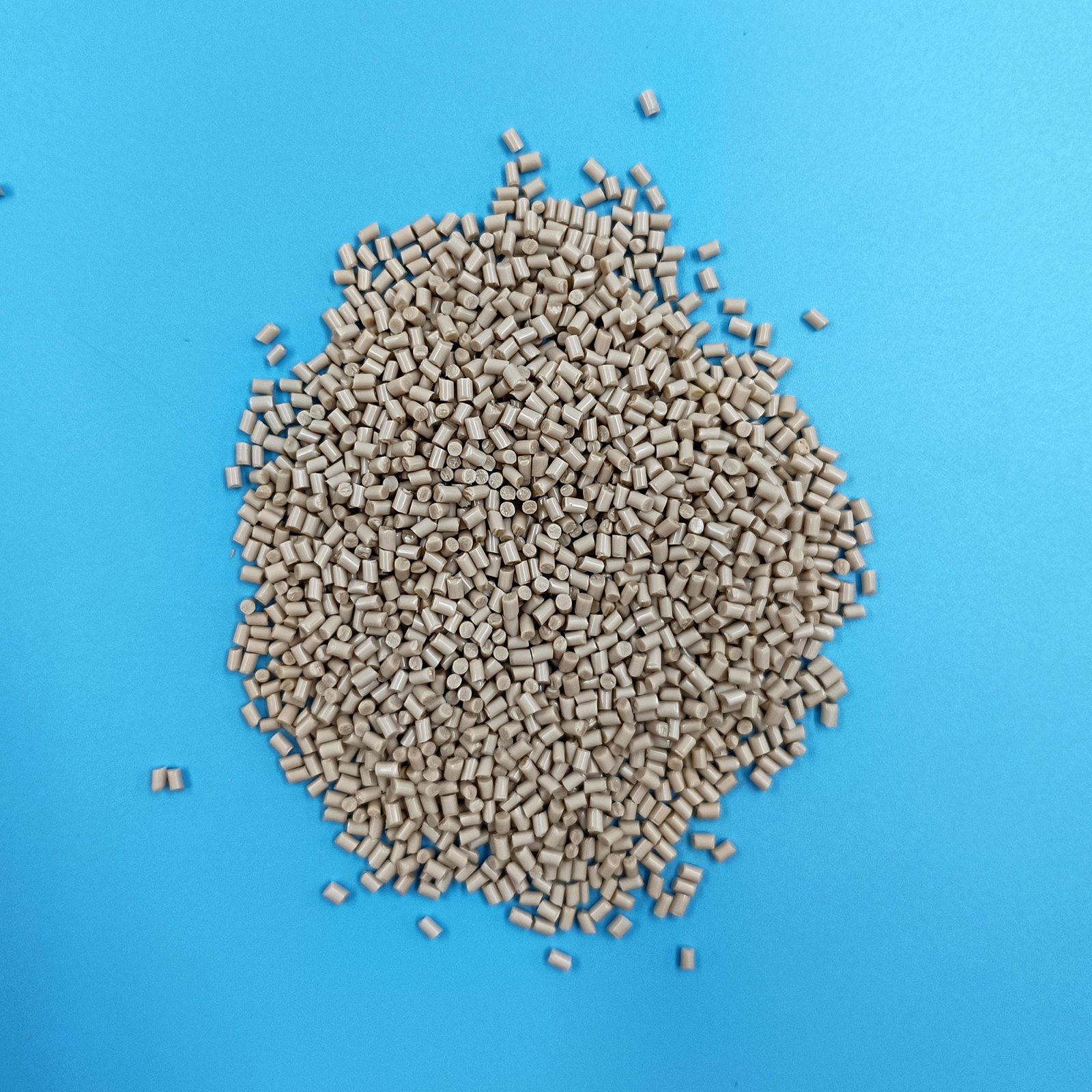

PEEK 021GF30 — Reinforced PEEK Plastic Material

โครงสร้างผลิตภัณฑ์

What is PEEK Plastic Material

Changchun Jida PEEK 021GF30 is a glass fiber reinforced PEEK plastic material, specially designed for engineering components with high strength and high heat resistance.

Based on the inherent thermal stability, chemical inertness and mechanical toughness of PEEK resin, 30% glass fiber reinforcement endows the material with higher structural rigidity and dimensional stability, enabling it to maintain stable performance under harsh working conditions.

This material has passed the UL94 V-0 flame retardant grade and features excellent heat distortion temperature and low water absorption rate. It is suitable for industries such as electronics, electrical appliances, automobiles, and medical care, which have extremely high requirements for heat load and precision.

01 | Material Highlights and Characteristics

Mechanically reinforced structure

-The 30% glass fiber reinforced structure increases the flexural modulus to over 9000MPa, and its structural strength is comparable to that of some metal parts.

-It features excellent creep resistance and fatigue resistance, making it suitable for long-term load-bearing components.

Heat-resistant and flame-retardant

-The continuous operating temperature can reach up to 260°C.

-It has passed the UL94 V-0 flame retardant test and can operate for a long time in an electrical environment.

ความเสถียรของมิติที่ยอดเยี่ยม

-Low water absorption rate and low shrinkage rate (about 0.9% in the flow direction, only 0.3% in the vertical direction);

-Suitable for precision parts that require close fit and repeated assembly.

Processing and Molding Advantages

-It has good injection molding fluidity (MFR 25g /10min), suitable for complex mold cavities and thin-walled products.

-Compatible with standard PEEK processing equipment, no additional investment is required.

Chemical and thermal aging stability

-It has excellent resistance to most chemicals, solvents and high-temperature oxidation environments.

-Even under long-term high temperature and humidity, it can maintain its original mechanical properties.

02 | Key Points of Processing and Technology

| Item | Recommended Parameter | Technical Note |

| Melt Temperature | 370–400°C | Ensures crystallinity and flow balance |

| Mold Temperature | 160–200 องศาเซลเซียส | Improves surface quality and dimensional stability |

| Drying Condition | 150°C × 3 hours | Prevents moisture-related streaks or bubbles |

| Injection Pressure | 100–150 MPa | Adjust according to part thickness and complexity |

Application suggestions:

-It is particularly suitable for structural components that require high-temperature durability and high mechanical loads.

-It is suitable for replacing metal materials, achieving the advantages of lightweight and corrosion resistance.

03 | Typical Application Fields

・Electronic and electrical: High-temperature connectors, insulating supports, sensor housings;

・Automobiles and aviation: Engine peripheral components, bearing housings, valve assemblies;

・Mechanical manufacturing: High-precision gears, pump housings, sliding seals;

・Medical equipment: Sterilizable components, structural brackets, and imaging equipment parts.

These application fields fully demonstrate the comprehensive advantages of PEEK 021GF30 as PEEK plastic material in terms of strength and stability.

04 | PEEK 021GF30 Data Sheet

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การยืดตัว | 23℃ | ISO 527 | 8.2 | % | |||

| ความแข็งแรงของแรงดัดงอ | 23℃ | ISO178 | 230 | MPa | |||

| โมดูลัสแรงดัดงอ | 23℃ | ISO178 | 9000 | MPa | |||

| ความต้านแรงดึง | 23℃ | ISO 527 | 160 | MPa | |||

| โมดูลัสแรงดึง | 23℃ | ISO 527 | 11200 | MPa | |||

| ชาร์ปี้ อิมแพ็คแบบไร้รอยบาก | 23℃ | ISO179 | 52 | กิโลจูล/ตรม | |||

| แรงกระแทกแบบชาร์ปี้ โนตช์ | ISO179 | 7 | กิโลจูล/ตรม | ||||

| ความร้อน | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ค่าสัมประสิทธิ์การนำความร้อน | ดิน 52612 | 0.3 | W/(ม·K) | ||||

| เอชดีที | ไม่ผ่านการอบอ่อน 1.80 MPa | ISO75 | 310 | ℃ | |||

| อุณหภูมิการหลอมละลาย | ISO11357 | 334 | ℃ | ||||

| อุณหภูมิเปลี่ยนผ่านของแก้ว | ISO11357 | 143 | ℃ | ||||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การดูดซึมน้ำ | 23℃ 24 ชม. | ISO62 | 0.04 | % | |||

| การหดตัว | ไหล | ISO294 | 0.9 | % | |||

| การหดตัว | xFlow | ISO294 | 0.3 | % | |||

| ความหนาแน่น | ISO1183 | 1.51 | กรัม/ซม.³ | ||||

| ดัชนีการหลอมละลาย | 400℃ 5kg | ISO 1133 | 25 | ก./10 นาที | |||

| ความแข็ง | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ความแข็งแบบร็อคเวลล์ | 88 | ||||||

| ความไวไฟ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ระดับเปลวไฟ | UL94 | วี-0 | |||||

05 | Frequently Asked Questions (FAQ)

Q1: What are the differences between PEEK 021GF30 and unreinforced PEEK?

A: 021GF30 contains 30% glass fiber reinforcement. Its mechanical strength, rigidity and heat resistance are significantly higher than those of pure resin-based PEEK, but its toughness is slightly lower accordingly, making it more suitable for structural components.

Q2: Can this material be used for food or medical contact?

A: This model is mainly designed for industrial and electronic applications. If medical-grade or contact applications are required, medical-certified PEEK models can be selected.

Q3: How difficult is the processing of PEEK 021GF30?

A: Good processability and moderate fluidity. A slightly higher mold temperature compared to conventional PEEK can achieve better crystallinity and dimensional accuracy.

Q4: Can it replace metal parts?

A: In most high-temperature environments, it can replace aluminum or stainless steel components with a lighter weight and stronger chemical resistance, achieving structural optimization and cost savings.

06 | Materials recommended by the same company

| ผู้ผลิต | รุ่นสินค้า | ความหนาแน่น | Melt Flow Index | ความต้านแรงดึง | การยืดตัว | การหดตัว | อุณหภูมิการหลอมละลาย | โมดูลัสแรงดึง | อุณหภูมิการเบี่ยงเบนความร้อน | ความแข็งแบบร็อคเวลล์ | โมดูลัสแรงดัดงอ | ความแข็งแรงของแรงดัดงอ |

| Changchun Jida | 021FC30 | 1.45 g/cm³ | 22 g/10min | 140 MPa | 8% | 0.70% | 334 ℃ | 11300 MPa | 290 ℃ | 85 | 10200 MPa | 205 MPa |

| Changchun Jida | 021G | 1.32 g/cm³ | 12 g/10min | 94 MPa | 40% | 1.30% | 334 ℃ | 3100 MPa | 150 ℃ | 87 | 3600 MPa | 155 MPa |

| Changchun Jida | 021CF30 | 1.4 g/cm³ | 25 g/10min | 220 MPa | 7.50% | 0.50% | 334 ℃ | 23500 MPa | 310 ℃ | 90 | 19000 MPa | 300 MPa |

| Changchun Jida | 021CF20 | 1.4 g/cm³ | 22 g/10min | 200 MPa | 8% | 0.50% | 334 ℃ | 21000 MPa | 310 ℃ | 90 | 10200 MPa | 280 MPa |

These models, together with PEEK 021GF30, form the PEEK product matrix of Changchun Jida, covering a wide range of scenarios from general engineering to high-end precision manufacturing.

07 | Summary

Changchun Jida PEEK 021GF30, as a high-rigidity glass fiber reinforced peek plastic material, performs well in terms of strength, thermal stability and molding adaptability, and is capable of meeting the demanding requirements ranging from automobiles to semiconductors.

For manufacturers who pursue material reliability and process stability, it is not only an effective alternative to metals, but also represents the mature direction of polymer engineering materials in high-end manufacturing fields.

【ข้อแนะนำที่เกี่ยวข้อง】

ColorRx® PEEK-3000RX: Medical-Grade peek raw material for Advanced Healthcare เรียนรู้เพิ่มเติม>

VESTAKEEP® 2000G | Flame-Retardant Medium-Viscosity PEEK เรียนรู้เพิ่มเติม>

The Role of Plastic Raw Materials in Fishing Nets: A Deep Dive into PA6 เรียนรู้เพิ่มเติม>