สินค้า

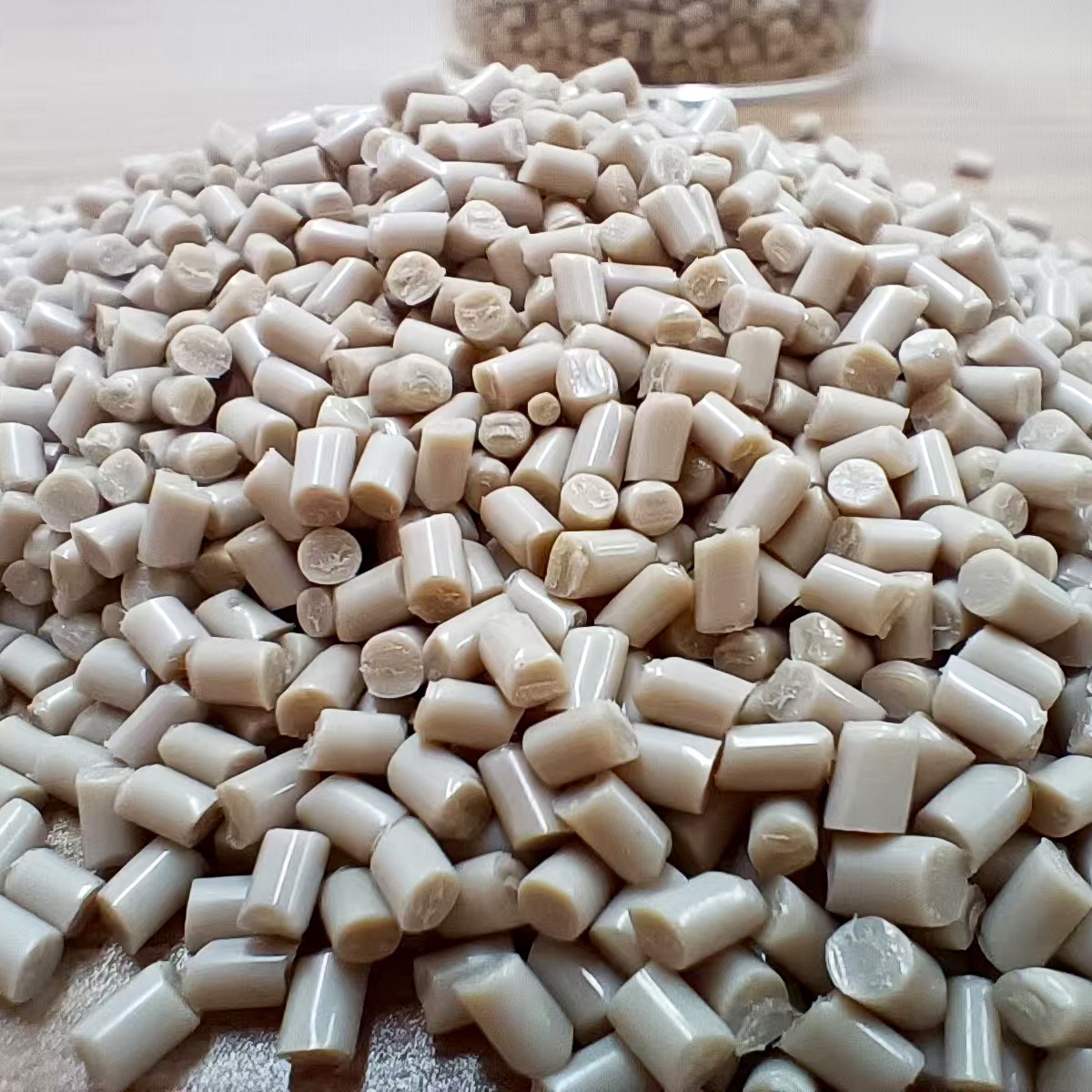

Lubrizol PEEK A-1440 CNT Reinforced Conductive PEEK Pellets

โครงสร้างผลิตภัณฑ์

What are PEEK Pellets

PEEK (Polyether Ether Ketone) is currently one of the high-temperature resins with the most balanced comprehensive performance among engineering plastics. Lubrizol peek A-1440 is A modified PEEK of the PEeK-CNt system pellets. Through carbon nanotube filling technology, it significantly improves electrical conductivity and electromagnetic shielding effect, while maintaining mechanical strength and dimensional stability.

This peek pellets can not only work in high-temperature environments for a long time, but also effectively prevent static electricity accumulation, which is crucial for the electronics industry.

01 | Analysis of Key Performance

| Property Category | Item | Data | วิธีการทดสอบ | คำอธิบาย |

| Mechanical Properties | ความต้านแรงดึง | 75 MPa | มาตรฐาน ASTM D638 | Provides sufficient structural support |

| โมดูลัสแรงดึง | 3800 MPa | มาตรฐาน ASTM D638 | Ensures dimensional stability of molded parts | |

| โมดูลัสแรงดัดงอ | 5180 MPa | ASTM D790 | Maintains deformation control for precision electronic components | |

| Notched Izod Impact | 52 J/m | มาตรฐาน ASTM D256 | Enhances impact resistance of finished parts | |

| Physical Properties | ความถ่วงจำเพาะ | 1.32 g/cm³ | ASTM D792 | Moderate density suitable for high-precision molding |

| การหดตัว | 1.70% | ASTM D995 | Ensures consistency in complex mold structures | |

| Electrical Properties | ความต้านทานพื้นผิว | 1E6 Ω | - | Meets static dissipation requirements |

| ความต้านทานปริมาตร | 1.00E+06 | - | Provides stable conductive pathways | |

| Static Decay | 0.1 s | - | Rapidly releases electrostatic charge to protect sensitive components |

Technical highlights

-Carbon nanotube reinforced structure: Endows the material with excellent electromagnetic shielding and electrical conductivity, while maintaining the thermal stability of PEEK itself.

-Outstanding mechanical and dimensional stability: Maintains reliable structural performance even in high-temperature environments.

-Low ion characteristics: Suitable for electronic-grade applications with high cleanliness requirements.

These properties make PEEK A-1440 an ideal peek pellets choice for electronic structural components, semiconductor equipment enclosures, etc.

02 | Application Scenarios and Industry Value

Lubrizol PEEK A-1440 peek pellets is mainly used in:

ชิ้นส่วนอิเล็กทรอนิกส์และไฟฟ้า

-Suitable for circuit board support parts, connectors, and sensor housings

-It has excellent electrostatic discharge and electromagnetic shielding performance

Aerospace electronic control components

-Replace the metal casing, reduce weight while enhancing EMI protection

Semiconductors and precision equipment

-Low-ion precipitated peek pellets is suitable for cleanroom process equipment

Automation and the new energy industry

-Anti-static housing and insulating brackets for control modules and drive components

03 | Suggestions on Processing and Forming

Lubrizol PEEK A-1440 peek pellets can be processed by injection molding or extrusion.

-Drying conditions: 150°C for 3 hours

-Melting temperature: 360-400°C

-Mold temperature: 160-200°C

-Processing precautions: The carbon nanotubes should be evenly dispersed to avoid local agglomeration which may affect electrical conductivity.

Thanks to its excellent fluidity and thermal stability, this peek pellets can achieve high-precision molding of complex-shaped electronic components.

04 | Industry Trends and Market Insights

With the development of electronic devices towards lightweight and high integration, the demand for conductive peek pellets continues to rise.

Compared with traditional carbon fiber reinforced materials, CNT-filled peek pellets has:

-A more uniform conductive network structure

-Stable electromagnetic shielding performance

-Better toughness and dimensional retention

-Meet the low ion release requirements of a clean electronic environment

Therefore, PEEK A-1440 has gradually become one of the mainstream materials in high-end electronic and new energy applications.

05 | Recommendations for Similar Performance and Applications

The following peek pellets is similar in performance and application to Lubrizol PEEK A-1440 and can be selected according to different project requirements:

| ผู้ผลิต | รุ่นสินค้า | ความถ่วงจำเพาะ | ความต้านแรงดึง | การยืดตัว | การหดตัว | โมดูลัสแรงดึง | อุณหภูมิการเบี่ยงเบนความร้อน | Izod Notched Impact | โมดูลัสแรงดัดงอ | Notched Impact |

| Lubrizol | F-1450 | 1.4 g/cm³ | 179 MPa | 3 % | 0.40~0.60 % | 9650 MPa | 300 ℃ | 59 J/m | 14500 MPa | 6.02 kJ/m² |

06 | Why choose PEEK Pellets provided by Juyuan

As a supplier with 24 years of experience in international plastic raw material trade, Juyuan is committed to providing customers with high-quality peek pellets and engineering plastic solutions:

-We supply a wide range of engineering particle raw materials such as PEEK, PEI, PPS and LCP worldwide

-Provide selection consultation, performance comparison and stable supply chain guarantee

-Our services cover multiple high-demand industries such as electronics, automobiles, aviation, healthcare, and energy

-With rich export experience, we ensure the compliance of raw materials and batch consistency

【ข้อแนะนำที่เกี่ยวข้อง】

October 2025 Virgin Plastic Raw Materials Market Insights | Juyuan Perspective เรียนรู้เพิ่มเติม>

RTP 2200 Series Low Flow PEEK Resin | 2200 LF to 2285 LF เรียนรู้เพิ่มเติม>

Americhem InLube™ Lubricated PEEK Polymer for Low-Friction Use เรียนรู้เพิ่มเติม>