สินค้า

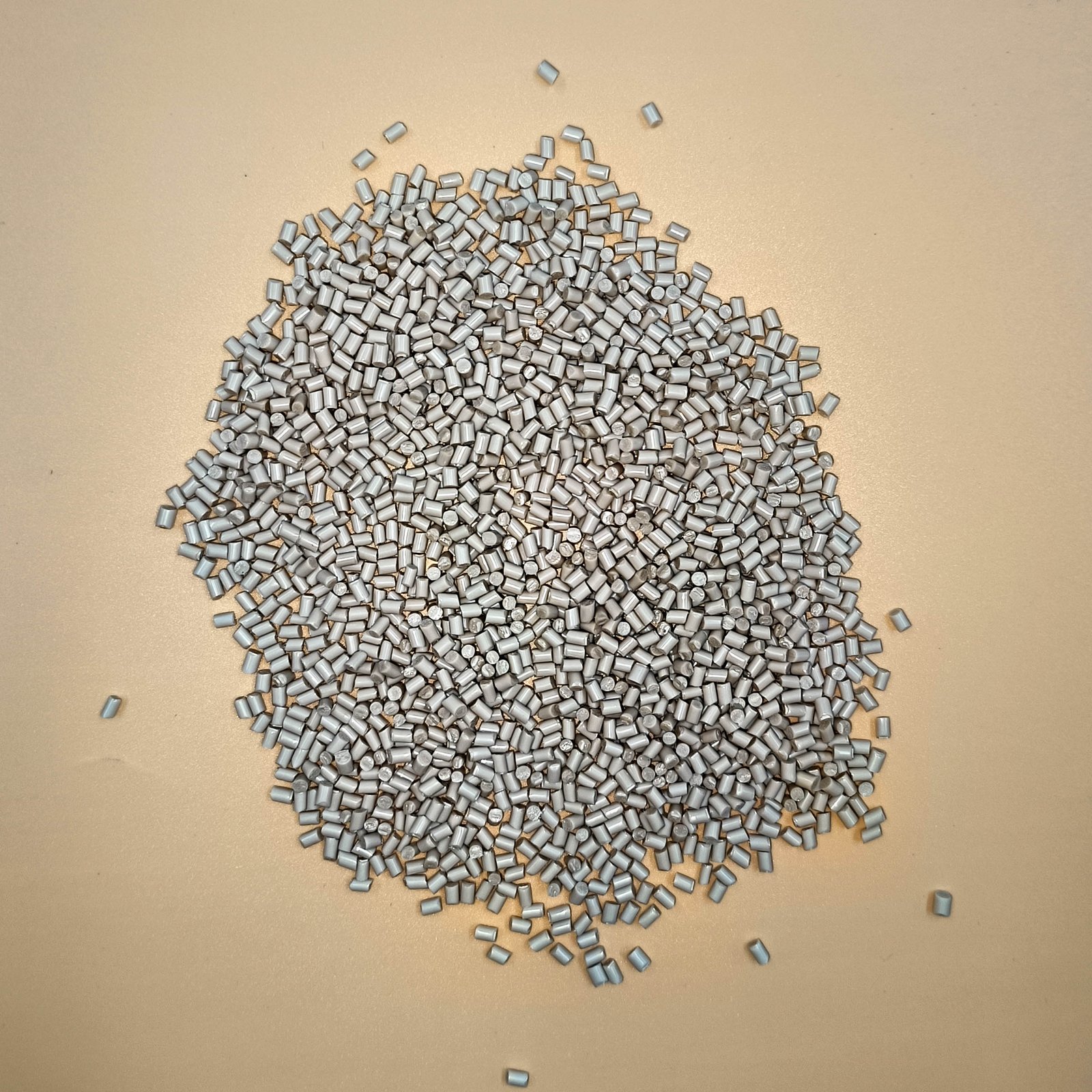

Lubrizol Carbo-Rite™ A-1441: Corrosion-Resistant PEEK Granules

โครงสร้างผลิตภัณฑ์

What are PEEK Granules

Lubrizol Carbo-Rite™ A-1441 is a granular PEEK alloy designed for industrial injection molded parts. Its semi-crystalline structure provides excellent dimensional stability, high rigidity, and corrosion resistance, making it suitable for industrial pallets, precision machinery parts, and chemically resistant parts.

Compared to traditional PEEK granules, Carbo-Rite™ A-1441 offers stable performance during the injection molding process. Its granular form ensures uniform melting, resulting in higher part precision and consistency.

01 | Material Advantages

Semi-crystalline structure: Provides stable mechanical and thermal properties, ensuring parts resist deformation even in high-temperature environments.

ความแข็งแกร่งสูง: Meets the strength requirements of industrial components, maintaining a stable shape even under high loads.

Dimensional stability: Low shrinkage ensures precision and consistency in injection-molded parts.

Corrosion resistance: Withstands a wide range of chemical environments, extending part life.

Peek Granules: Peek granules facilitate injection molding, ensuring uniform melting and high production efficiency.

02 | Process Compatibility and Selection Recommendations

Carbo-Rite™ A-1441 granules are suitable for injection molding processes:

High flow and low warpage: Maintain high precision even for complex geometric parts.

Temperature Control Recommendations: Adjust the injection temperature based on part thickness and mold structure to ensure a uniform melt.

Material Modification: Impact resistance, wear resistance, or chemical resistance can be adjusted according to customer requirements.

Juyuan provides comprehensive selection guidance to help customers select the material type that best suits their part requirements.

03 | Typical Applications

Industrial Pallets and Containers: High rigidity, chemical resistance, and suitable for repeated use.

Precision Machinery Parts: Low shrinkage ensures dimensional accuracy, suitable for high-precision components such as gears and guides.

Parts for Chemical Environments: Acid and alkali corrosion resistance extends equipment life.

Electrical Insulation Parts: Provides reliable insulation performance, suitable for light-duty electrical applications.

04 | Carbo-Rite™ A-1441 Granules Data Sheet

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การยืดตัว | ผลผลิต | มาตรฐาน ASTM D638 | 2.9 | % | |||

| โมดูลัสแรงดัดงอ | ASTM D790 | 18000 | MPa | ||||

| อิซอด นอทช์ อิมแพ็ค | มาตรฐาน ASTM D256 | 7.50 | กิโลจูล/ตรม | ||||

| ความต้านแรงดึง | หยุดพัก | มาตรฐาน ASTM D638 | 80 | MPa | |||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การหดตัว | Flow 3.2mm 395°C Mold Temperature:190°C | วิธีการภายใน | 0.17~0.22 | % | |||

| การหดตัว | xFlow 3.2mm 395°C Mold Temperature:190°C | วิธีการภายใน | 0.65~0.71 | % | |||

| ความหนาแน่น | ASTM D792 | 1.35 | กรัม/ซม.³ | ||||

| คุณสมบัติทางไฟฟ้า | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ความต้านทานปริมาตร | ANSI/ESD STM11.12 | 2.4E+4 | Ω.ซม | ||||

| ความต้านทานพื้นผิว | ANSI/ESD STM11.11 | 2.6E+4 | โอห์ม | ||||

05 | Industry Trends

With the increasing demand for high-temperature, high-rigidity, and chemical resistance in industrial parts, PEEK granules have become the material of choice for high-end manufacturing. Carbo-Rite™ A-1441, combining การฉีดขึ้นรูป processability, corrosion resistance, and high dimensional stability, has broad application prospects in the automotive, electronics, precision machinery, and chemical equipment sectors.

06 | FAQs

Q1: What is the difference between Carbo-Rite™ A-1441 and standard PEEK?

A1: It is a modified PEEK alloy. While maintaining PEEK's basic heat resistance, it also offers improved conductivity and dimensional stability, making it particularly suitable for anti-static and high-precision structural parts.

Q2: Can this material be modified for color or properties?

A2: Yes. Juyuan offers customized solutions such as carbon nanotube reinforcement, glass fiber filling, and antistatic agent adjustment based on customer processing requirements.

Q3: What parameters should be paid special attention to during injection molding?

A3: We recommend a mold temperature between 180–200°C and a melt temperature of approximately 390–400°C for optimal crystallization and dimensional accuracy.

Q4: Does Juyuan provide technical support?

A4: Yes. Juyuan provides comprehensive support, from material selection and process recommendations to production commissioning, to ensure you maximize the performance potential of your peek granules.

07 | Juyuan's Exclusive Advantages

As a professional international trader of PEEK granules, Juyuan provides customers with:

Technical Support: Professional engineers provide material selection advice and processing guidance.

Customized Solutions: Recommend modified materials or customized formulations based on customer needs.

Stable Supply: Ensure timely delivery of granules to meet the needs of large-volume orders.

Foreign Trade Service Experience: Extensive export experience helps customers successfully complete international procurement.

08 | Summary

Lubrizol Carbo-Rite™ A-1441 PEEK granules not only offer the technical advantages of high rigidity, dimensional stability, and corrosion resistance, but also, through Juyuan's technical support, modification solutions, and cost-effective supply, help customers obtain stable and reliable solutions for industrial parts production.

【ข้อแนะนำที่เกี่ยวข้อง】

Lubrizol PEEK A-1440 CNT Reinforced Conductive PEEK Pellets เรียนรู้เพิ่มเติม>

RTP 2200 Series Low Flow PEEK Resin | 2200 LF to 2285 LF เรียนรู้เพิ่มเติม>

Americhem InLube™ Lubricated PEEK Polymer for Low-Friction Use เรียนรู้เพิ่มเติม>