สินค้า

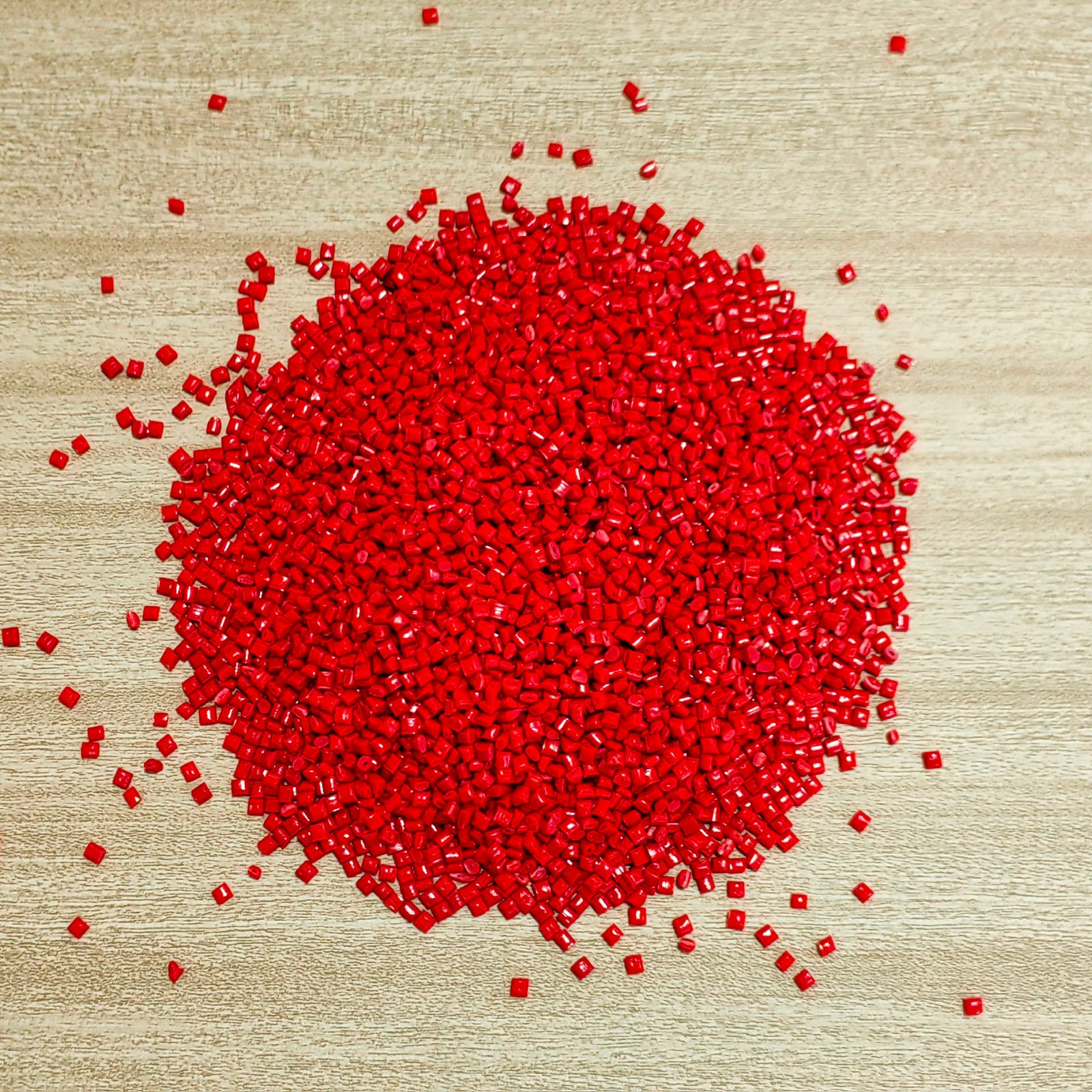

Lehmann & Voss LUVOCOM® PPSU Series

โครงสร้างผลิตภัณฑ์

What is LUVOCOM® PPSU

The LUVOCOM® PPSU series of Raymanfos includes a variety of engineering-grade plastic particles, such as 1502-7867/BL4, 1502-7865/BK2, 1502-8752, and 1502-7866/GN4. They all possess outstanding heat resistance, flame retardancy and mechanical strength, and are suitable for high-demand applications in medical, electronic, electrical, automotive and other fields.

I. Common Advantages of the LUVOCOM® Series

High-temperature resistance: Heat distortion temperature 210℃, meeting the requirements of repeated high-temperature environments.

Flame retardant grade V-0: Ensures safety in electronic, electrical and transportation applications.

Stable mechanical properties: Balanced strength and modulus, suitable for structural components.

Low water absorption rate and shrinkage rate: Good molding accuracy and dimensional stability.

Excellent electrical insulation: Both volume and surface resistance are at the 10^12 level.

Ii. Comparison of Model Differences

| Grade / Model | Density (g/cm³) | Tensile Strength (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) | Melt Flow Index (g/10min) | คุณสมบัติ |

| LUVOCOM® 1502-7867/BL4 | 1.33 | 75 | 110 | 2000 | 45 | Blue-black, general-purpose |

| LUVOCOM® 1502-7865/BK2 | 1.3 | 75 | 110 | 2000 | 45 | Black, lightweight |

| LUVOCOM® 1502-8752 | 1.44 | 78 | 115 | 2200 | 40 | High modulus, preferred for structural parts |

| LUVOCOM® 1502-7866/GN4 | 1.32 | 75 | 110 | 2000 | 45 | Green, for visual identification |

Iii. Process Compatibility and Processing Suggestions

Molding method: Suitable for injection molding. The mold design can draw on the experience of PC or PSU materials.

อุณหภูมิหลอมละลาย: The recommended processing temperature range is 360-390℃, with good fluidity.

สภาวะการอบแห้ง: Before processing, it is necessary to dry thoroughly (120-150℃, 3-4 hours) to avoid the formation of silver streaks or bubbles during the molding process.

อุณหภูมิแม่พิมพ์: Maintaining it at 140-160℃ can achieve better surface quality and dimensional accuracy.

Secondary processing: Suitable for mechanical processing, ultrasonic welding, and hot air welding.

Color and appearance: The series offers black, blue-black, green, etc., which can meet the needs of appearance or functional differentiation.

Iv. Application Recommendations

Medical devices: surgical tool housings, dental equipment, sterilization-resistant components.

Electronic and electrical: Electrical connectors, switch sockets, insulating parts.

Automobiles and transportation: Lightweight alternatives to metals, high-temperature resistant electrical components.

อุปกรณ์อุตสาหกรรม : Pumps and valves, transparent Windows, chemically resistant components.

V. Selection Suggestions

High modulus and structural strength requirements → PPSU 1502-8752

Lightweight, black appearance → PPSU 1502-7865/BK2

General application, universal type → PPSU 1502-7867/BL4

Appearance identification/Green Requirements → PPSU 1502-7866/GN4

Vi. Frequently Asked Questions (FAQ)

Q1: Is LUVOCOM® PPSU resistant to high-temperature steam sterilization?

A: Yes, PPSU has excellent high-temperature resistance and hydrolytic stability. It can withstand multiple steam sterilizations without significant performance degradation.

Q2: What are the main differences among various models?

A: Mainly in terms of specific gravity, strength and color. For instance, 8752 has a higher modulus and is suitable for structural components. The 7865 is lighter and suitable for lightweight requirements.

Q3: Is drying necessary before molding?

A: Yes, it is recommended to dry at 120-150℃ for 3-4 hours to avoid molding defects.

Q4: Can it be used for transparent parts?

A: The LUVOCOM® series mainly features colored models (black, blue-black, green). If transparent PPSU is required, Solvay Radel® PPSU can be considered.

Q5: Does Juyuan offer small-batch samples?

A: Yes, we support small-batch samples to facilitate customers' sampling and process validation.

Vii. Similar Recommendations

RTP PPSU series: Commonly used in medical and electronic applications.

Ensinger TECASON P MT: Medical-grade PPSU, biocompatible.

Solvay RADEL® PPSU: Widely applied in aviation and medical standards.

Viii. Why Choose Juyuan

Covering multiple models of LUVOCOM® series PPSU in stock

Free samples and small-batch trial material support are provided

Rich experience in international trade and fast delivery

The professional technical team provides material selection and processing suggestions

【ข้อแนะนำที่เกี่ยวข้อง】

EDGETEK™ RA-10GF-10CF/000 HI High Strength PPSU Resin เรียนรู้เพิ่มเติม>

TECASON P MT Polyphenylsulfone for Medical & Industrial Use เรียนรู้เพิ่มเติม>

FDA Food Grade Plastics: A Must-Read for Purchasing Food-Grade Plastics เรียนรู้เพิ่มเติม>