สินค้า

LATILUB 95-25GR CE/10 vs 95-15T | Self-Lubricating Comparison

โครงสร้างผลิตภัณฑ์

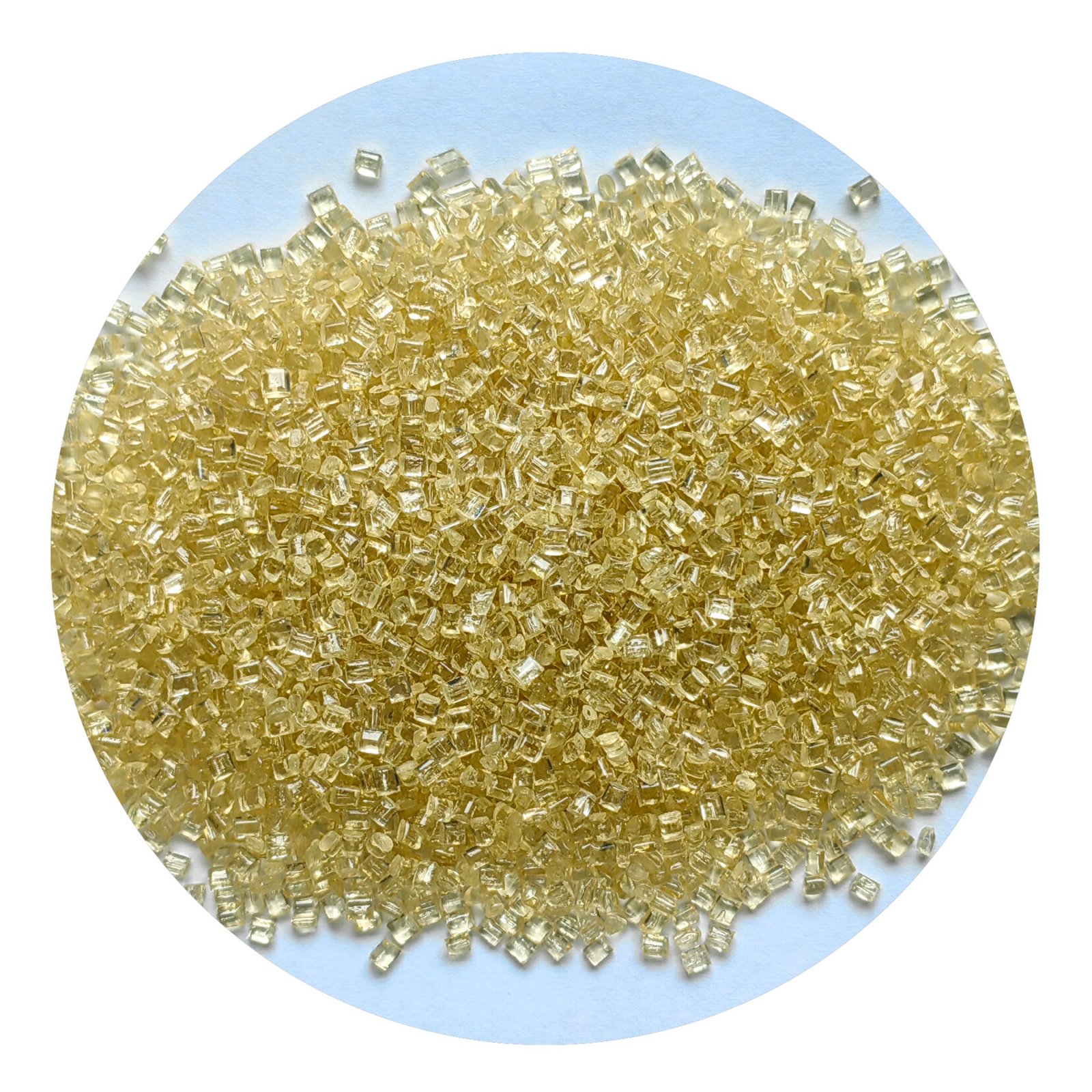

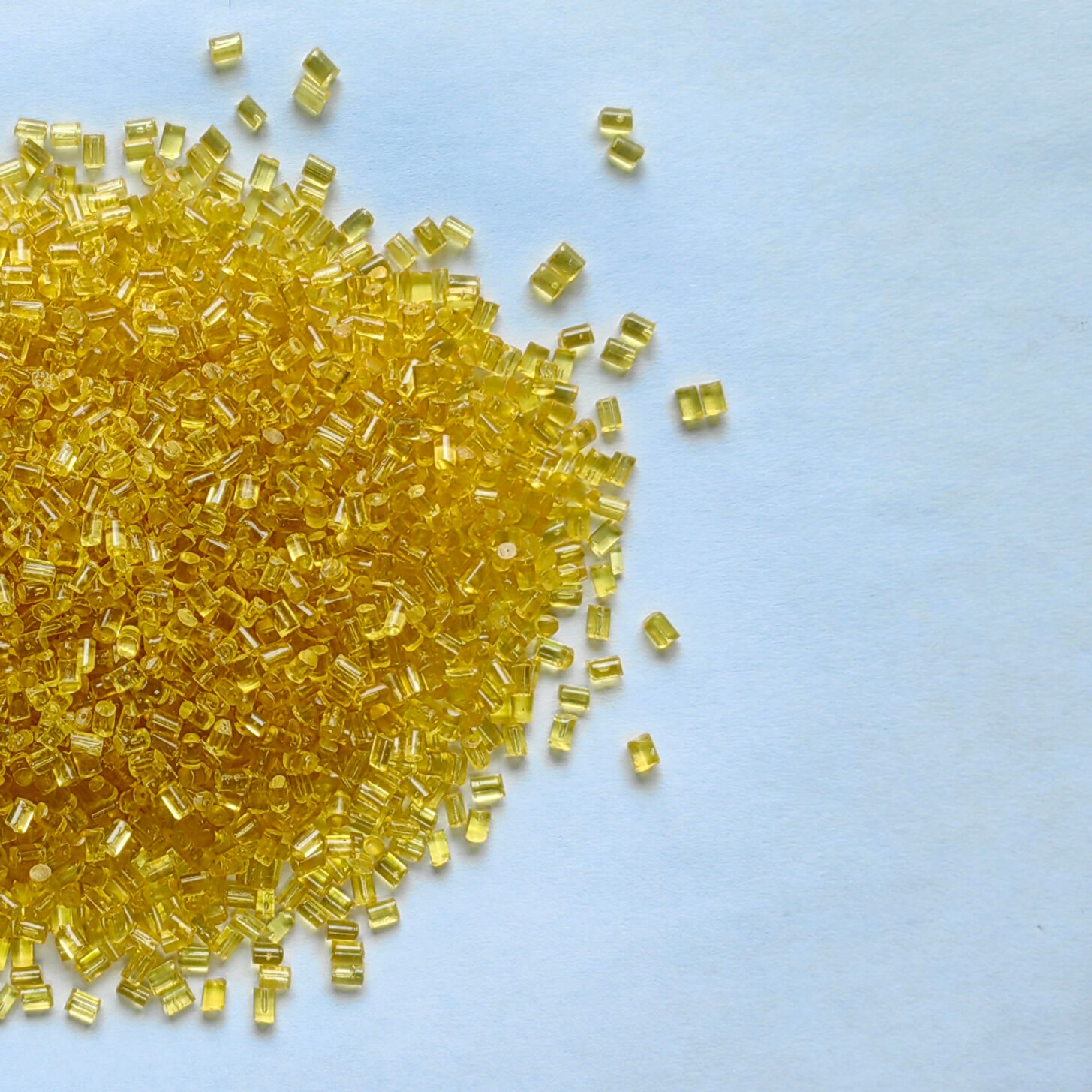

What is LATILUB PSU

The LATILUB PSU series of materials is constructed from a modified polysulfone (PSU) base material, featuring PTFE and graphite lubricants to impart long-lasting self-lubricating properties. This article will provide a systematic analysis of the PSU 95-25GR CE/10 and PSU 95-15T models to help users make informed decisions when selecting components.

I. Common Characteristics

Material Base: Both are based on polysulfone (PSU), offering excellent heat resistance and dimensional stability.

Self-lubricating Performance: Both incorporate PTFE lubricant, significantly reducing wear in friction pairs.

Comparable Thermal Properties: Both have heat deflection temperatures around 170°C and Vicat softening temperatures of 180°C, making them suitable for high-temperature friction applications.

Typical Applications: Both can replace some metal parts in mechanical friction components, electrical components, the automotive industry, and the medical industry.

II. Differentiated Performance Comparison

| คุณสมบัติ | PSU 95-25GR CE/10 | PSU 95-15T |

| Filler | 10% mineral filled | Unfilled |

| Lubrication System | Graphite + PTFE | PTFE only |

| ความต้านแรงดึง | 65 MPa | 90 MPa |

| โมดูลัสแรงดึง | 8500 MPa (high stiffness) | 1800 MPa (good flexibility) |

| การยืดตัวเมื่อขาด | 1.2% (brittle) | 5% (better impact resistance) |

| Notched Impact Strength | 2 kJ/m² (lower) | 7 kJ/m² (better) |

| การหดตัว | 0.4–0.55% (dimensionally stable) | 1.1–1.2% (higher shrinkage) |

| ความหนาแน่น | 1.49 g/cm³ (higher density) | 1.35 g/cm³ (lighter) |

Mechanical Properties

・95-25GR CE/10: Due to its 10% mineral filler content, it exhibits extremely high rigidity (tensile modulus 8500 MPa) and enhanced dimensional stability, making it suitable for parts requiring strict deformation control.

・95-15T: Features improved toughness and impact resistance (unnotched impact strength up to 70 kJ/m²), making it suitable for applications subject to dynamic impact or bending stress.

Shrinkage and Dimensional Accuracy

-The 95-25GR CE/10 has a shrinkage of only 0.4–0.55%, superior to the 95-15T (1.1–1.2%), making it particularly advantageous for precision part injection molding.

III. Advantages and Disadvantages Analysis

PSU 95-25GR CE/10

Advantages:

-High modulus (8500 MPa), excellent rigidity, and long-term dimensional stability.

-Graphite + PTFE dual lubricant provides excellent dry friction durability.

-Low shrinkage, suitable for high-precision injection molded parts.

Disadvantages:

-Low toughness and low impact resistance.

-Brittle, not suitable for parts subject to high impact loads.

-High specific gravity, increasing part weight.

การใช้งาน: Gears, sliders, bearing seats, medical precision components, electrical structural parts.

PSU 95-15T

Advantages:

-High tensile strength (90 MPa) and excellent impact resistance (70 kJ/m² unnotched).

-5% elongation and good toughness.

-Specific gravity lower than 95-25GR CE/10, making it lighter.

Disadvantages:

-Low modulus (1800 MPa) and less rigidity than 95-25GR CE/10.

-Using a single PTFE lubrication system, slightly shorter wear life.

-High shrinkage and limited dimensional accuracy.

การใช้งาน: Guide rails, bushings, pump and valve components, and mechanical parts subject to impact.

IV. Application Comparison Summary

Precision Parts: If dimensional accuracy and rigidity are key, then 95-25GR CE/10 is the more suitable choice.

Impact Resistance: If parts are subject to dynamic loads and shock, then 95-15T is the more suitable choice.

Wear Life: In heavy-duty friction applications, 95-25GR CE/10 offers longer life due to the synergistic lubrication of graphite and PTFE.

Lightweighting: 95-15T has a lower density, making it more conducive to weight reduction.

V. Buyer FAQs

Q1: Can these two materials replace metal parts?

A: In wear-resistant and light-duty friction applications, they can certainly do so. However, for applications involving high impact or high loads, this requires evaluation based on the actual design.

Q2: What are the differences during processing?

A: 95-25GR CE/10 has a low shrinkage rate, resulting in stable processed dimensions. 95-15T has a high shrinkage rate, requiring additional compensation in mold design.

Q3: Will the lubricant precipitate?

A: Both utilize an internal lubrication system, forming a transfer film during long-term friction, preventing large-scale precipitate.

Q4: Which lubricant should be used in the automotive industry?

A: For interior slide rails and gears, choose 95-25GR CE/10; for bushings and dynamic friction parts, choose 95-15T.

VI. Juyuan's Supply Advantages

Although both LATILUB PSU 95-25GR CE/10 and PSU 95-15T are self-lubricating modified PSUs, they are positioned differently: the former emphasizes rigidity and dimensional accuracy, while the latter emphasizes toughness and impact absorption. When purchasing, you can make an appropriate selection based on the part's load pattern, dimensional requirements, and friction conditions.

As an international plastic raw material trader, Juyuan offers a stable supply channel for the LATILUB PSU series. With material selection advice, processing support, and international logistics, we help customers in the machinery, automotive, medical, and electrical industries secure more reliable raw material supplies.

【ข้อแนะนำที่เกี่ยวข้อง】

QUADRANT® PSU unfilled | Heat Resistant PSU Polysulfone เรียนรู้เพิ่มเติม>

LASULF G/20 | Stable & Low Smoke Polysulfone Plastic เรียนรู้เพิ่มเติม>

Plastics for Power Tools: Selection & Procurement Guide | Juyuan เรียนรู้เพิ่มเติม>