สินค้า

DURADEX® D-3000 Series PPSU Material Grades Overview

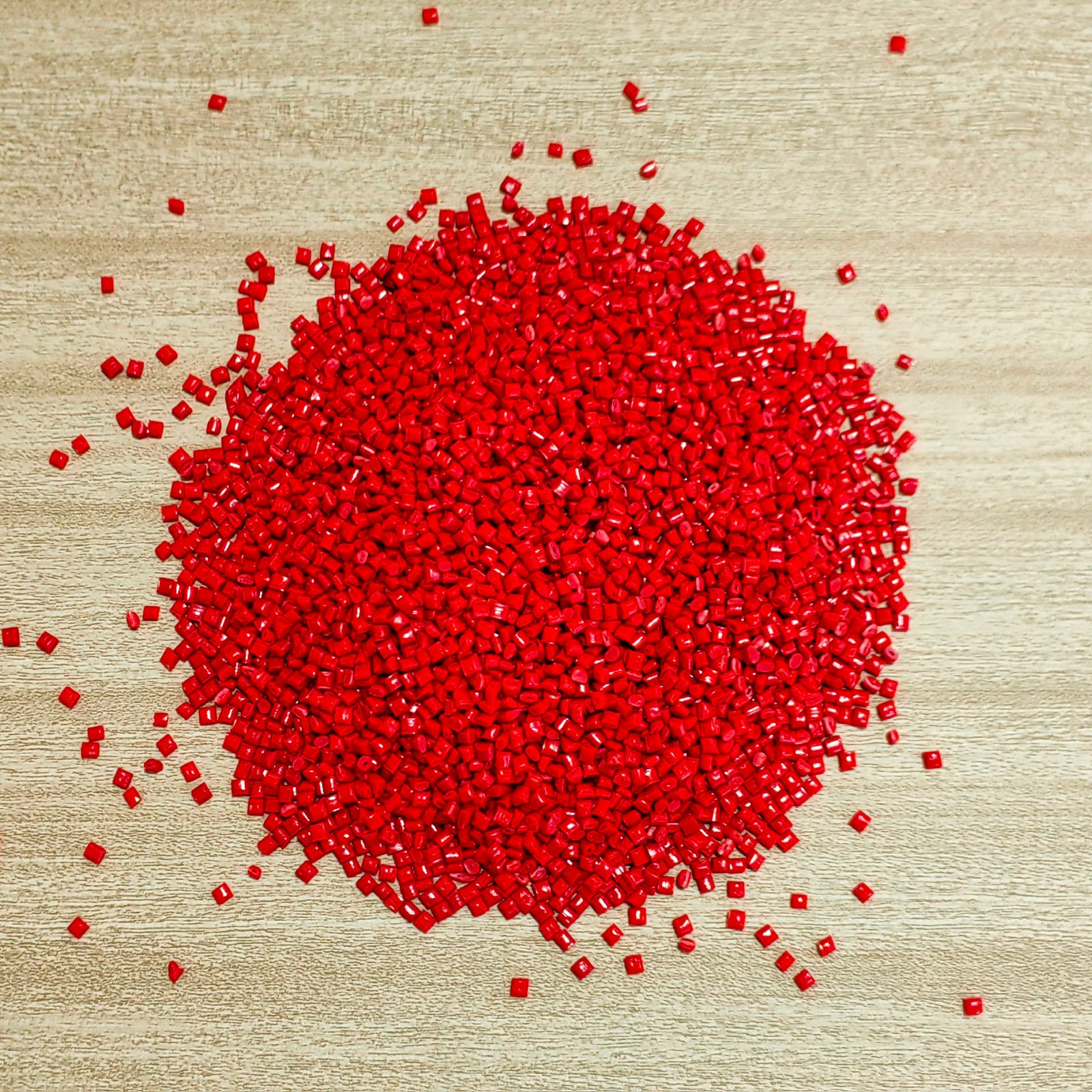

โครงสร้างผลิตภัณฑ์

What is DURADEX® PPSU

การ DURADEX® series from Solvay is based on polyphenylene sulfone (PPSU), a material valued for its ability to handle high temperatures, repeated sterilization, และ mechanical stress without performance loss. Because of this balance of properties, DURADEX grades are widely adopted in medical devices, drinking water systems, electrical insulation, และ ชิ้นส่วนยานยนต์ where reliability and safety are non-negotiable.

As an international supplier, Juyuan provides the full product range and supports customers with free samples to speed up evaluation and material selection.

1. Shared Advantages of the DURADEX Series

Heat resistance: Glass transition temperature of 220 °C; HDT (1.8 MPa, annealed) at 204 °C.

Flame retardancy: All thicknesses (0.75–3.0 mm) achieve UL94 V-0; glow wire up to 960 °C.

Strength and toughness: Tensile strength 70 MPa, flexural strength 100 MPa, notched Izod impact 640 J/m.

Dimensional stability: Low shrinkage (0.7%), water absorption 0.37%, maintaining accuracy after molding.

Electrical insulation: Volume resistivity 1E19 Ω·cm; dielectric strength 36 kV/mm.

2. Grade Comparison and Typical Uses

DURADEX D-3000 NT (Natural)

-คุณสมบัติ: Neutral base resin, suitable for secondary coloring or applications demanding high cleanliness.

-Uses: Medical devices, water fittings, food-contact components.

DURADEX D-3000 BK 937 (Black)

-คุณสมบัติ: Pre-colored black, saves coloring steps, strong opacity.

-Uses: Automotive housings, insulation parts, industrial enclosures.

DURADEX D-3000 TR GY 391 (Transparent Gray)

-คุณสมบัติ: Semi-transparent gray, functional plus aesthetic, allows visual monitoring.

-Uses: Medical fluid systems, filters, transparent technical housings.

DURADEX D-3000 BB (Blue-Black)

-คุณสมบัติ: Blue-black tone, strong identity and decorative effect.

-Uses: Consumer electronics, appliance housings, branded components.

DURADEX D-3000 CL 191 (Transparent)

-คุณสมบัติ: Clear transparency, good optical properties.

-Uses: Medical windows, fluid containers, visible piping systems.

3. Comparison of Different Models and Application Recommendations

| Grade / Model | รูปร่าง | คุณสมบัติหลัก | Recommended Applications |

| D-3000 NT | เป็นธรรมชาติ | Standard grade, high cleanliness, suitable for re-coloring | Medical parts, food contact components |

| D-3000 BK 937 | Black | Strong opacity, no need for secondary coloring | Automotive parts, electrical housings |

| D-3000 TR GY 391 | Transparent Grey | Semi-transparent, combines visibility and aesthetics | Medical components, fluid conduits |

| D-3000 BB | Blue-Black | High decorative appeal and easy identification | Consumer goods, electronic housings |

| D-3000 CL 191 | Transparent | Nearly clear, ideal for visualization requirements | Transparent medical parts, liquid containers |

Application Areas:

Medical: Handles for surgical instruments, sterilizable housings, dental tools.

Water and Food: Coffee machine components, water dispenser connectors, filter casings.

Electrical & Electronics: Socket housings, insulating parts, switchgear.

Automotive: Pump housings, high-temperature ducts, under-hood components.

Consumer Goods: Heat-resistant tableware, transparent kitchenware.

4. Processing Guidelines

Primary method: Injection molding, suitable for medium-flow designs (Melt Flow Index 30 g/10 min at 365 °C/5 kg).

Drying: 120 °C for 3–4 h, target moisture <0.02% to prevent streaks or bubbles.

Molding temperature: 350–400 °C; mold 150–180 °C for good surface finish and properties.

Equipment: Wear-resistant screws recommended to minimize resin degradation.

Secondary operations: PPSU can be CNC-machined, drilled, or cut; retains properties after steam sterilization (up to 1000+ cycles).

5. FAQs

Q1: How does PPSU compare with PSU and PEI?

PPSU delivers higher impact resistance and thermal stability, making it more suitable for applications requiring repeated sterilization.

Q2: Is DURADEX PPSU safe for food and water contact?

Yes. The grades are widely used in hot water connectors, filter housings, and food service parts.

Q3: Do transparent grades discolor with use?

They maintain clarity well under normal use. For long UV exposure, additional protection is advised.

Q4: Can the material withstand autoclaving?

Yes. DURADEX PPSU resists more than 1,000 sterilization cycles without notable performance loss.

Q5: How can I order or request samples?

Juyuan supplies the complete DURADEX series and provides free samples for qualification testing.

6. Why Source from Juyuan?

Full range coverage: NT, BK 937, TR GY 391, BB, CL 191.

Global trade expertise: 24 years of cross-border supply chain experience.

Free evaluation samples: Reduce risk before committing to large orders.

Technical support: Material selection, processing advice, and application guidance.

【ข้อแนะนำที่เกี่ยวข้อง】

EDGETEK™ RA-10GF-10CF/000 HI High Strength PPSU Resin เรียนรู้เพิ่มเติม>

TECASON P MT Polyphenylsulfone for Medical & Industrial Use เรียนรู้เพิ่มเติม>

Lehmann & Voss LUVOCOM® PPSU Series เรียนรู้เพิ่มเติม>