สินค้า

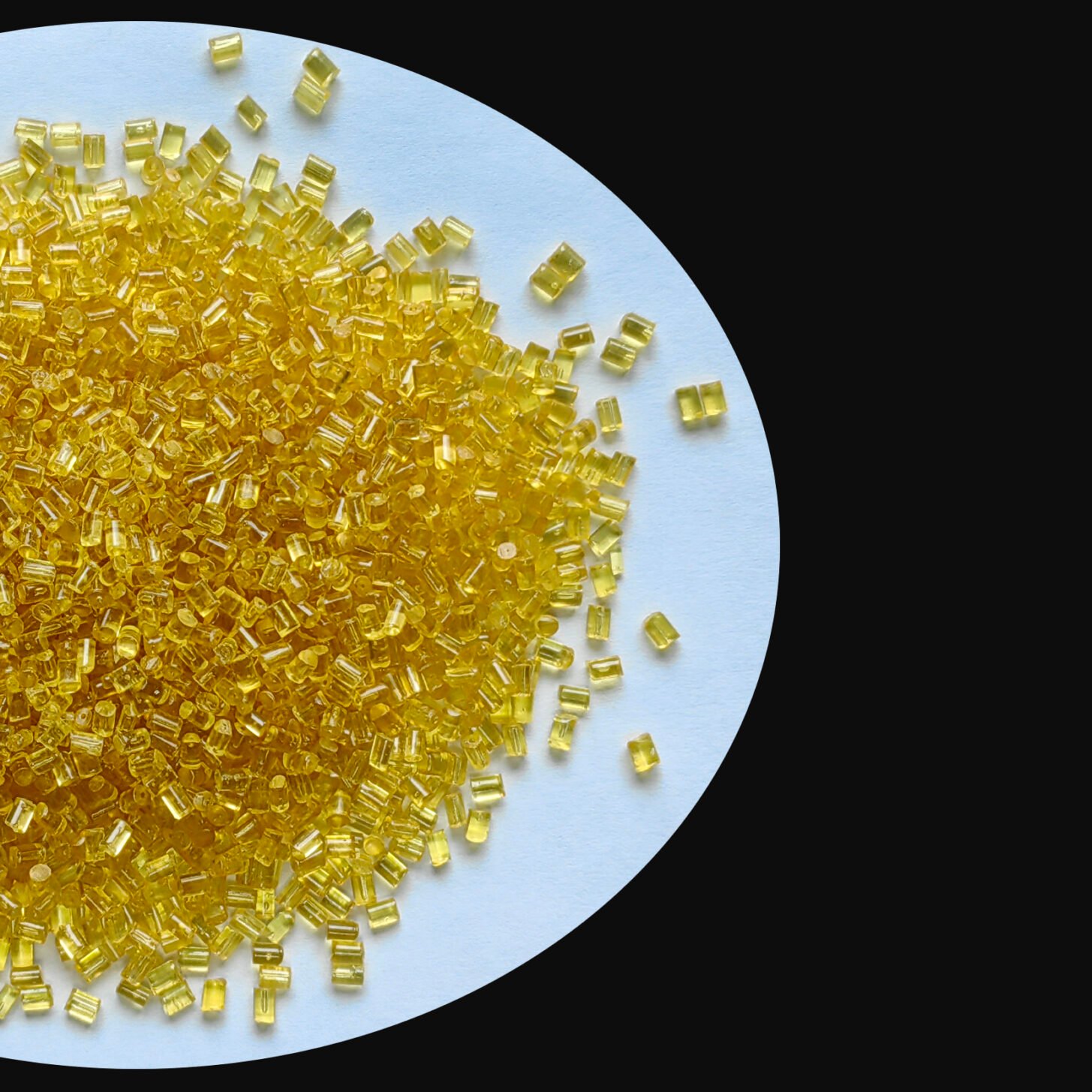

ColorRx® PSU-1000RX | Medical-Grade PSU for Biocompatibility

โครงสร้างผลิตภัณฑ์

What is ColorRx® PSU-1000RX

ColorRx® PSU-1000RX is a medical-grade polysulfone (PSU) particle launched by Americhem, specifically designed for medical care and related precision applications. This material not only possesses the consistent heat resistance and hydrolysis resistance of polysulfone resin, but also has passed the biocompatibility certification, making it safe for use in medical devices and care products.

01 | Material Properties

Medical-grade certification: Complies with the safety and biocompatibility standards required for medical devices.

High-temperature resistance: The heat deflection temperature can reach up to 345℉ (approximately 174℃), maintaining stable performance in high-temperature environments.

Mechanical stability: Tensile strength of 10,000 psi, flexural modulus of 390,000 psi, balancing toughness and rigidity.

Chemical and hydrolytic stability: Water absorption rate as low as 0.30%, suitable for long-term contact with cleaning agents and disinfectants.

Flexible processing: Melt index 6.5g /10min (300℃/1.2kg), supports injection molding, which is conducive to efficient production.

02 | Typical Uses

ColorRx® PSU-1000RX is widely used in:

・Medical care supplies: infusion instruments, dialysis equipment shells, monitor accessories.

・Reusable sterilizable components: high-pressure steam sterilization handles, medical operation components.

・High-temperature nursing equipment: ventilator components, operating room instrument casings.

03 | Process compatibility

วิธีการประมวลผล: Injection molding, with good fluidity, suitable for complex thin-walled parts.

Suggested forming parameters: The barrel temperature should be around 300℃, and the mold temperature should be controlled within 150℃ to ensure the stability of appearance and dimensions.

Post-treatment: To ensure performance, it is recommended to dry it moderately before use to avoid moisture causing bubbles or a decline in mechanical properties.

04 | ColorRx® PSU-1000RX Data Sheet

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การยืดตัว | เบรก 50มม./นาที | มาตรฐาน ASTM D638 | 50~100 | % | |||

| โมดูลัสแรงดัดงอ | 50มม./นาที | ASTM D790 | 390000 | พลังจิต | |||

| อิซอด นอทช์ อิมแพ็ค | 23℃ | มาตรฐาน ASTM D256 | 1.3 | ฟุต-ปอนด์/นิ้ว | |||

| ความต้านแรงดึง | ผลผลิต 50มม./นาที | มาตรฐาน ASTM D638 | 10000 | พลังจิต | |||

| ความร้อน | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| เอชดีที | 1.80MPa 3.20mm | มาตรฐาน ASTM D648 | 345 | ℉ | |||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การดูดซึมน้ำ | 24 ชม. | มาตรฐาน ASTM D570 | 0.30 | % | |||

| การหดตัว | Flow 3.20mm | มาตรฐาน ASTM D955 | 0.007 | in/in | |||

| ความหนาแน่น | ASTM D792 | 1.24 | กรัม/ซม.³ | ||||

| ดัชนีการหลอมละลาย | 300℃ 1.2kg | มาตรฐาน ASTM D1238 | 6.5 | ก./10 นาที | |||

05 | Industry Trends and Values

The medical-grade plastic market has grown rapidly in recent years, with the demand focus gradually shifting from traditional low-end materials such as PVC and PP to high-performance engineering plastics.

・Sustainability: The durability and repeatable sterilization properties of ColorRx® PSU-1000RX reduce single-use plastic waste.

・Compliance: With the increasingly strict regulation of medical devices, choosing PSU materials that meet international certifications has become an industry trend.

・Alternative metals: Lightweight and resistant to chemical corrosion, it is gradually replacing some metal components.

06 | Frequently Asked Questions (FAQ)

Q1: Can ColorRx® PSU-1000RX be used for food contact?

A: This grade is mainly targeted at medical-grade applications. If it involves food contact, additional confirmation and certification are required.

Q2: Can the material withstand repeated high-pressure steam sterilization?

A: Yes, with a heat distortion temperature of 174℃ and a low water absorption rate, it is suitable for repeated sterilization environments.

Q3: What are the advantages compared with PC (polycarbonate)?

A: ColorRx® PSU-1000RX is more stable in high-temperature environments and has better chemical resistance than PC, making it suitable for more demanding medical scenarios.

07 | Similar recommendations

If you are interested in ColorRx® PSU-1000RX, you may also refer to the following polysulfone engineering plastics:

| ผู้ผลิต | Grade / Model | ความหนาแน่น | ความต้านแรงดึง | การยืดตัว | การหดตัว | โมดูลัสแรงดึง | อุณหภูมิการเบี่ยงเบนความร้อน | ความแข็งแบบร็อคเวลล์ | Izod Impact | โมดูลัสแรงดัดงอ | Izod Impact (Unnotched) | ความแข็งแรงของแรงดัดงอ |

| Antep | 902 Z | 1.34 g/cm³ | 89.6 MPa | 3.50% | 0.20% | 5520 MPa | 185 ℃ | 122 | 69.4 J/m | 4830 MPa | 481 J/m | 131 MPa |

| Antep | AG-360 | 1.57 g/cm³ | 117 MPa | 2.50% | 0.20% | 8960 MPa | 199 ℃ | 74.7 J/m | 7930 MPa | 534 J/m | 172 MPa | |

| Antep | 900 TFE 10 Z | 1.29 g/cm³ | 62.1 MPa | 6.50% | 0.50% | 2410 MPa | 174 ℃ | 64.1 J/m | 2550 MPa | 1330 J/m | 100 MPa | |

| Antep | 900.5 | 1.27 g/cm³ | 75.8 MPa | 8% | 0.65% | 3030 MPa | 174 ℃ | 58.7 J/m | 3170 MPa | 1330 J/m | 119 MPa | |

| Antep | 900 GF-130 | 1.49 g/cm³ | 107 MPa | 2.0~3.0 % | 0.20~0.30 % | 8274 MPa | 179 ℃ | 123 | 64 J/m | 7584 MPa | 427 J/m | 155 MPa |

| Antep | M-825 Z | 1.45 g/cm³ | 68.9 MPa | 0.60% | 3790 MPa | 174 ℃ | 53.4 J/m | 4140 MPa | 121 MPa | |||

| Antep | B-360 | 1.52 g/cm³ | 138 MPa | 2% | 0.20% | 11000 MPa | 154 ℃ | 85.4 J/m | 10700 MPa | 587 J/m | 207 MPa | |

| Americhem | แหล่งจ่ายไฟ | 1.24 g/cm³ | 10000 psi | 10% | 0.005~0.007 in/in | 345 ℉ | 1.3 ft-lb/in | 390000 psi | ||||

| Americhem | PSU1700 | 1.24 g/cm³ | 10200 psi | 50~100 % | 0.007 in/in | 345 ℉ | 1.3 ft-lb/in | 390000 psi | 15000 psi |

08 | The supply advantage of Juyuan

As an international plastic raw material trader with 24 years of experience, Juyuan offers customers:

・Multi-channel procurement guarantee: Ensure a stable supply of ColorRx® PSU-1000RX and other PSU grades.

・Professional selection support: Based on the customer's product requirements, we recommend the most suitable engineering plastics.

・Global trade experience: Covering industries such as healthcare, electronics, and automobiles, providing one-stop services from material selection to delivery.

【ข้อแนะนำที่เกี่ยวข้อง】

Medical-Grade PSU P-1700 LCD | Medical-Grade Udel® PSU เรียนรู้เพิ่มเติม>

Udel® P-1700 NT 11 | Medical & Food Contact Grade PSU เรียนรู้เพิ่มเติม>

PSU GF20 | 20% Glass Fiber Reinforced Polysulfone for Medical เรียนรู้เพิ่มเติม>