Automotive Plastic Raw Materials

The global auto industry is clearly in the middle of a once-in-a-century shift. Electrification, lightweighting, intelligent systems, and sustainability are no longer buzzwords—they have become everyday concerns for R&D teams and supply managers. One interesting side effect is that the role of plastics is growing rapidly. From exterior body parts to battery housings and intricate control modules, plastics are steadily replacing metals.

They bring obvious benefits—lighter cars, more design flexibility, lower costs—but also create a real challenge for buyers: how to make sure performance is reliable, costs are under control, and supply chains don’t break down. This is a question we hear often in conversations with procurement managers.

01 | New Industry Dynamics: EVs and Sustainability

A few recent developments illustrate the trend:

-In Europe, major automakers like BMW and Mercedes-Benz are planning to use more plastics for lightweighting. Some engineers we spoke with say the shift is happening faster than expected.

-China’s new energy vehicle exports grew more than 20% year-on-year in the first half, which obviously drives demand for engineering plastics.

-Meanwhile, regulators are tightening requirements. The EU, for example, has set a 2025 target requiring at least 25% of automotive plastics to come from recycled sources.

So for buyers, the decision isn’t just about price anymore. They are weighing heat resistance, lightweighting, compliance, and, increasingly, the stability of global supply.

02 | Why Plastics Matter in Cars

Lightweighting

-Lower density reduces overall weight. A 10% weight drop can mean 6–8% less fuel use or longer EV range.

Design flexibility

-Plastics allow integrated, complex parts. Fewer pieces and faster assembly mean lower production costs.

Resistance to chemicals and corrosion

-Unlike metals, plastics won’t rust. This is especially important in oil- and fluid-contact components.

Safety and comfort

-Flame-retardant grades enhance electrical safety. Other engineered plastics cut vibration and noise, improving ride comfort.

Compatibility with new energy systems

-Battery housings, high-voltage connectors, lightweight brackets—all rely on plastics that combine heat resistance, flame retardancy, and insulation.

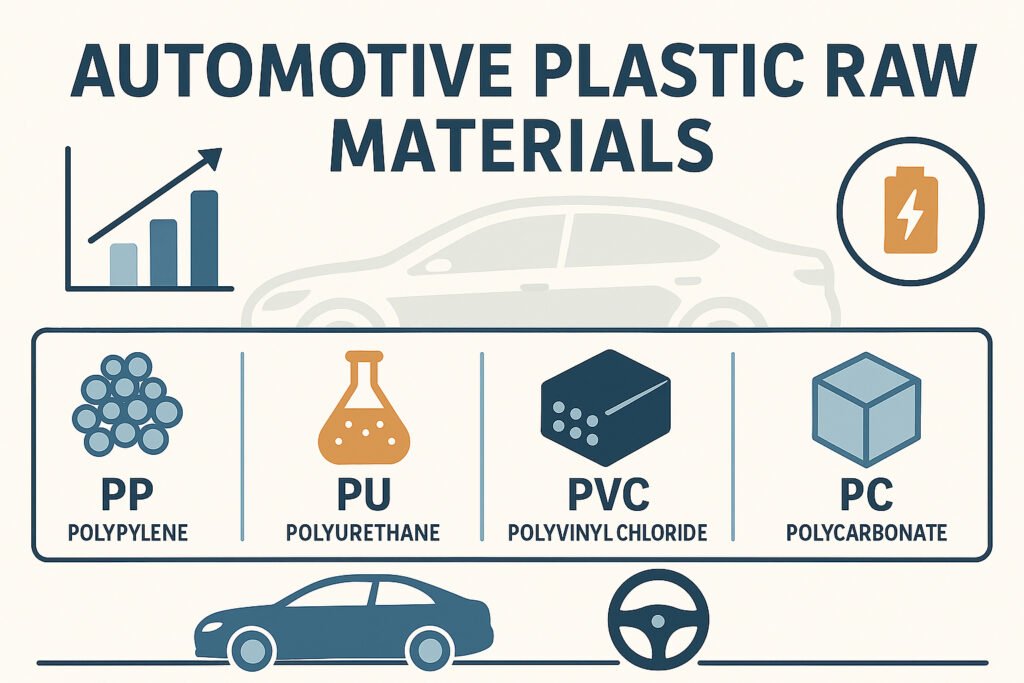

03 | Common Plastic Materials in Automotive Applications

Here’s a quick rundown of the most widely used materials. (Sources vary—trade reports, supplier surveys, and market studies—but the patterns are consistent.)

-Use: bumpers, dashboards, door panels, battery housings

-Why: light, inexpensive, chemically resistant

-Note: Roughly 30% of all auto plastics today are PP.

Polyurethane (PU)

-Use: seats, steering wheels, foams

-Why: cushioning and comfort

-Note: Still the favorite for interiors.

Polyvinyl Chloride (PVC)

-Use: seals, interior trim, cable sheathing

-Why: flame retardant, abrasion- and water-resistant

-Use: headlights, instrument lenses, sunroofs

-Why: transparency, impact strength

-Trend: steadily rising in lighting systems.

-Use: under-the-hood parts, manifolds, gears

-Why: heat and oil resistance, durability

ABS (Acrylonitrile-Butadiene-Styrene)

-Use: consoles, decorative trim

-Why: rigid, good surface quality, easy to process

PBT (Polybutylene Terephthalate)

-Use: connectors, sensors, electrical parts

-Why: insulation, heat resistance

-Note: Key for EV high-voltage connectors.

-Use: gears, fuel system parts, seat adjusters

-Why: high rigidity, low friction, self-lubricating

-Use: engine/electrical components, battery systems

-Why: excellent high-temp and chemical resistance

High-Performance Plastics (PEEK, แหล่งจ่ายไฟ, กปปส, etc.)

-Use: EV batteries, electronics, fluid systems

-Why: extreme heat resistance, dimensional stability

-Trend: penetration rate is climbing quickly in smart and electric vehicles.

04 | What Buyers Tell Us Are the Hardest Problems

When we talk to purchasing managers, a few recurring concerns always come up:

-Material selection: Matching the right plastic to the right function isn’t straightforward.

-Balancing cost and performance: Lightweight and durable often pull in opposite directions.

-Compliance pressures: Export models must meet EU, US, and other regional standards.

-Supply chain risks: Geopolitics, logistics bottlenecks, and sudden price swings are real worries.

05 | How Juyuan Helps

We work with buyers in Europe, Asia, and beyond, and our role is often about simplifying complexity:

-Stable global sourcing – covering Europe, Japan, Korea, and China.

-One-stop selection – from PP to PEEK, we recommend materials by application, not just by price.

-Modification options – reinforcement, flame retardancy, lubrication, etc.

-Compliance guaranteed – materials tested to meet RoHS, REACH, UL, and more.

06 | บทสรุป

The auto sector is pushing forward with electrification and sustainability. Plastics have become a core enabler, but the challenge for buyers is how to choose wisely—balancing cost, performance, compliance, and supply stability. From our experience, the companies that manage this balance well will hold a clear competitive edge.

For that reason, we see our role not just as a supplier but as a partner—helping clients navigate materials, processing, and supply chain issues in one place.