สินค้า

TECASON P MT Polyphenylsulfone for Medical & Industrial Use

โครงสร้างผลิตภัณฑ์

TECASON® P MT

In the fields of medical devices, food processing and high-end industries, materials are not merely components but also crucial to the lifespan, safety and compliance of products. As the industry's demands for high-temperature resistance, flame retardancy, biocompatibility and other properties continue to rise, traditional materials are gradually revealing their limitations: although metals are strong, they are heavy and prone to corrosion; Although ordinary plastics are lightweight, they are difficult to withstand high-temperature steam disinfection or complex chemical environments.

Against this backdrop, TECASON® P MT Polyphenylsulfone launched by Ensinger stands out. This material combines the lightness of engineering plastics with medical-grade reliability, making it the preferred choice for medical, food and industrial customers seeking high-performance solutions.

1. Material Highlights and Characteristics

High-temperature resistance: It still maintains mechanical strength in an environment exceeding 200℃ and is suitable for long-term high-temperature scenarios.

Outstanding disinfection resistance: It can withstand hundreds of high-pressure steam sterilizations while still maintaining transparency and toughness.

High strength and flame retardancy: With UL94 V-0 grade, it ensures flame retardancy while maintaining excellent impact strength.

ความเข้ากันได้ทางชีวภาพ: Meets medical-grade application standards and can be directly used in products that come into contact with the human body.

Dimensional stability: Low water absorption rate and good chemical resistance ensure long-term stable performance in complex environments.

2. Typical Uses

Medical field: surgical handles, dental equipment, transparent shells, reusable consumables.

Food and drinking water: Valves, joints, pump bodies and other parts that come into contact with food and drinking water.

Aviation and transportation: High-strength lightweight structural components, meeting the requirements of flame retardancy and impact resistance.

Electrical and Electronic: Insulating components, electrical enclosures and high-performance connectors.

3. TECASON® P MT Polyphenylsulfone Data Sheet

| พฤติกรรมทางกล | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การยืดตัว | 23℃ | มาตรฐาน ASTM D638 | 60 | % | |||

| ความแข็งแรงในการบีบอัด | มาตรฐาน ASTM D695 | 98.94 | MPa | ||||

| ความแข็งแรงของแรงดัดงอ | 23℃ | ASTM D790 | 91 | MPa | |||

| โมดูลัสแรงดัดงอ | 23℃ | ASTM D790 | 2410 | MPa | |||

| อิซอด อิมแพ็คอันโน๊ตช์ | มาตรฐาน ASTM D256 | 694 | เจ/ม | ||||

| ความต้านแรงดึง | ผลผลิต 23°C | มาตรฐาน ASTM D638 | 69.6 | MPa | |||

| โมดูลัสแรงดึง | 23℃ | มาตรฐาน ASTM D638 | 2340 | MPa | |||

| ความร้อน | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| เอชดีที | ยังไม่อบอ่อน 0.45MPa | มาตรฐาน ASTM D648 | 220 | ℃ | |||

| เอชดีที | ไม่ผ่านการอบอ่อน 1.80 MPa | มาตรฐาน ASTM D648 | 216 | ℃ | |||

| คลี | ไหล | มาตรฐาน ASTM D696 | 3.1E-4 | ซม./ซม./℃ | |||

| อุณหภูมิการทำให้นิ่มของ Vicat | มาตรฐาน ASTM D1525 | 218 | ℃ | ||||

| คุณสมบัติทางกายภาพ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| การดูดซึมน้ำ | 23℃ 24 ชม. | มาตรฐาน ASTM D570 | 1.1 | % | |||

| ความหนาแน่น | ASTM D792 | 1.29 | กรัม/ซม.³ | ||||

| คุณสมบัติทางไฟฟ้า | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ค่าคงที่ไดอิเล็กตริก | 60เฮิรตซ์ | มาตรฐาน ASTM D150 | 3.44 | ||||

| ความต้านทานปริมาตร | มาตรฐาน ASTM D257 | 1E15 | Ω.ซม | ||||

| ความแข็งแรงของฉนวนไฟฟ้า | มาตรฐาน ASTM D149 | 14.2 | เควี/มม | ||||

| ความแข็ง | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ความแข็งแบบร็อคเวลล์ | R(สเกล) | มาตรฐาน ASTM D785 | 123 | ||||

| ความไวไฟ | เงื่อนไข | มาตรฐาน | ค่า | หน่วย | |||

| ระดับเปลวไฟ | UL94 | วี-0 | |||||

Technical Data Overview of TECASON® P MT Polyphenylsulfone

4. Technology and Processing Techniques

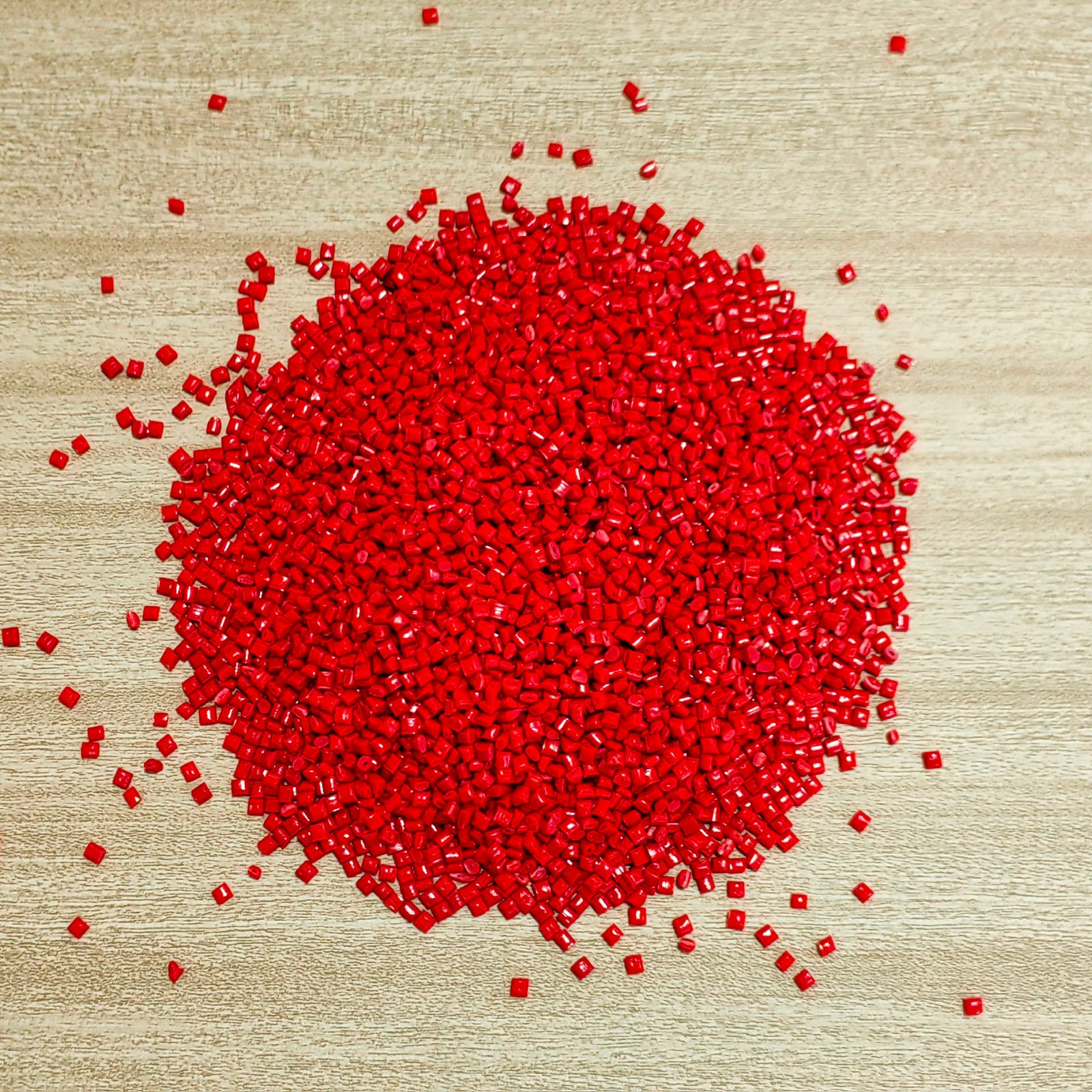

TECASON® P MT Polyphenylsulfone is produced by injection molding process and can produce granular raw materials, compatible with standard thermoplastic processing equipment.

・Injection molding: Suitable for complex medical components and precision parts.

・Machining: Suitable for small-batch and high-precision parts customization.

・Transparency and natural color features: They offer design flexibility and can be used in medical and industrial scenarios that require visualization.

5. Innovation and Industry Competitive Advantage

Compared with traditional materials:

-Compared with metals: It is lighter, more corrosion-resistant and easier to process.

-Compared with engineering plastics such as PSU and PEI, it has stronger heat resistance and disinfection resistance, and more outstanding impact resistance.

-Compared with general plastics, it has significant advantages in mechanical strength, flame retardancy and compliance.

This differentiated characteristic makes TECASON® PMT Polyphenylsulfone the preferred alternative material for the medical and high-end industries.

6. Customer Feedback

European medical device manufacturers: After using this material, the lifespan of the devices has increased by 40%, significantly reducing the cost of consumable replacement.

Food processing enterprises: In high-temperature cleaning environments, the performance of components remains stable, ensuring food safety.

Aviation parts supplier: By adopting this material, lightweight design has been achieved while meeting flame retardant regulations.

7. Frequently Asked Questions (FAQ)

Q1: How many times of high-temperature steam sterilization can this material withstand?

A1: It remains transparent and resilient even after hundreds of repeated autoclaving cycles.

Q2: Does it comply with international medical and food contact standards?

A2: Yes, TECASON® PMT Polyphenylsulfone complies with multiple medical and food safety regulations.

Q3: What are the advantages compared with PSU and PEI?

A3: This material is superior in terms of high-temperature resistance, hydrolysis resistance and impact strength, making it suitable for more demanding application scenarios.

8. Similar Recommendations

In addition to TECASON® PMT Polyphenylsulfone, Enxingge also provides:

| Grade / Model | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Notched Impact Strength | Heat Deflection Temp (℃, 1.8MPa) | Continuous Use Temp (℃) | Medical Suitability |

| Radel 5500 Black | 79 | 2340 | 91 | 160 J/m | 207 | 149 | ✓ (Food contact / Medical) |

| P Polyphenylsulfone | 69.6 | 2340 | 91 | 694 J/m (unnotched) | 216 | - | - |

| P MT XRO Bone | 79 | 2900 | 124 | 85 J/m | - | 149 | ✓ (Medical grade, bone color) |

9. Our Advantages as an Export Supplier

Selecting materials is just the first step; choosing a reliable supply partner is the key.

Multi-category coverage: We not only supply TECASON® PMT Polyphenylsulfone, but also offer a variety of high-performance engineering plastics.

In-stock and fast delivery: Always in stock, shorten delivery time, and meet urgent orders.

Technical support: Provide material selection guidance, processing suggestions and industry application solutions.

International service network: Supports multilingual communication and global logistics to ensure worry-free cross-border transactions.

Competitive pricing: Relying on stable channels and large-scale supply, we help customers reduce costs.

10. Conclusion

In high-demand medical, food and industrial applications, TECASON® PMT Polyphenylsulfone is not merely a material, but a systematic solution to help customers address core issues such as short lifespan, safety risks, compliance difficulties and high costs.

Choosing us as a partner means choosing reliable materials, perfect services and a stable supply chain.

【ข้อแนะนำที่เกี่ยวข้อง】

RADEL® 5500 Black – Multi-Color Medical-Grade PPSU Material เรียนรู้เพิ่มเติม>

RTP PPSU 1400 Series – Durable, Heat & Food Safe Resin เรียนรู้เพิ่มเติม>

FDA Food Grade Plastics: A Must-Read for Purchasing Food-Grade Plastics เรียนรู้เพิ่มเติม>