สินค้า

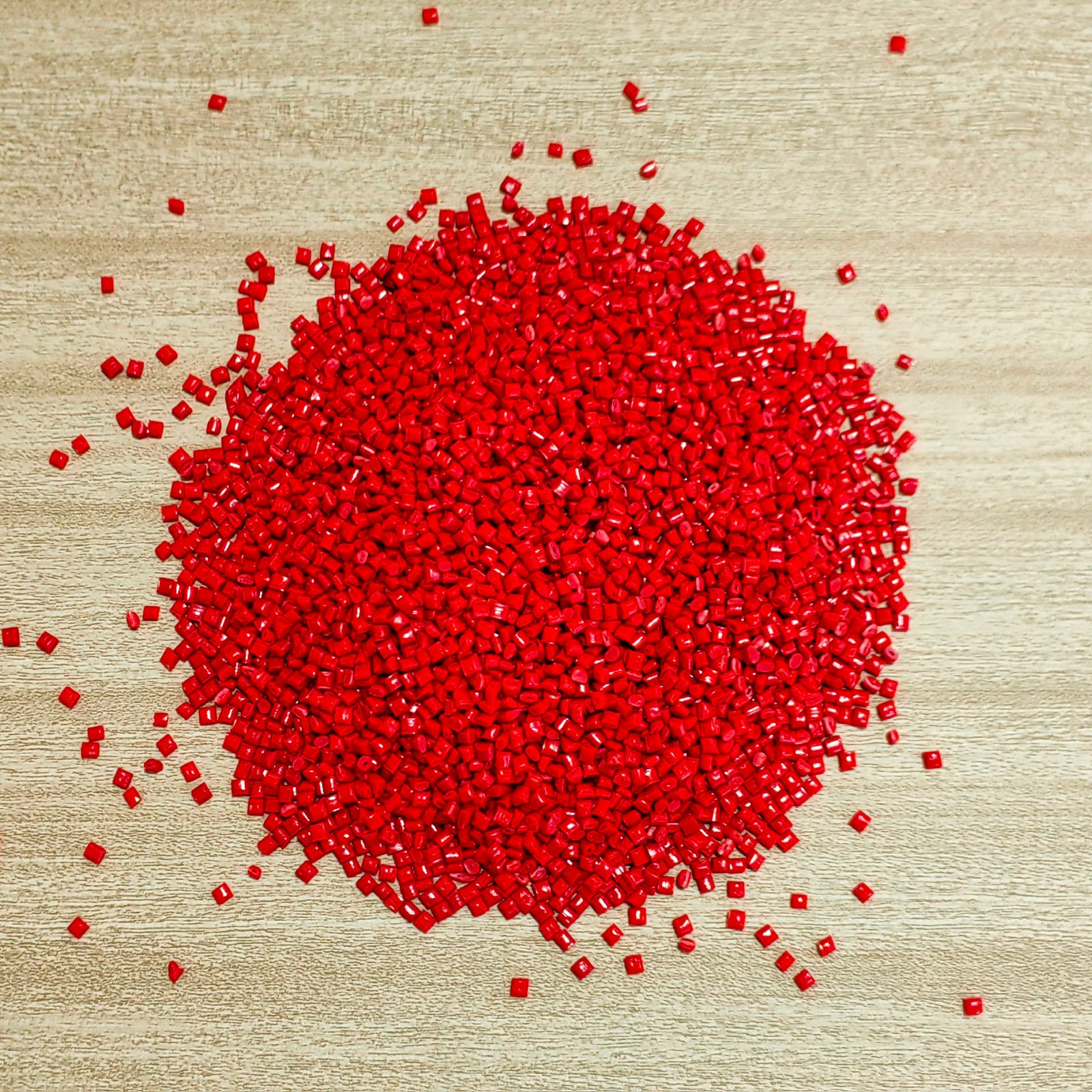

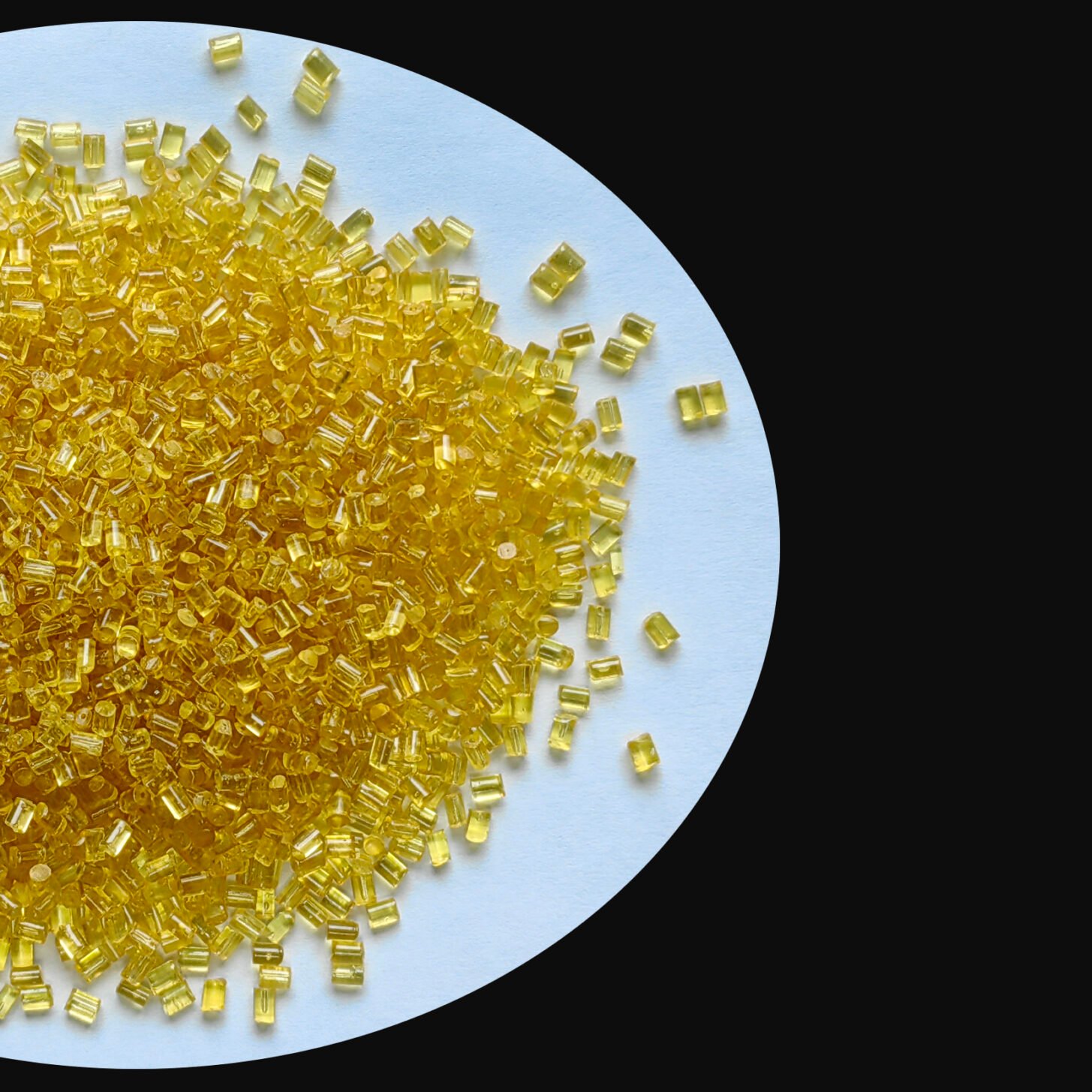

HiFill® PPSU Series: Tailored Plastics for Demanding Applications

โครงสร้างผลิตภัณฑ์

What is HiFill® PPSU

Among engineering plastics, polyphenylsulfone (PPSU) is often the preferred material when strength, heat resistance, and flame retardancy must be combined in one solution. It is widely adopted in medical equipment, aerospace, electronics, and advanced industrial fields. TECHMER PM’s HiFill® PPSU series builds on the well-known benefits of PPSU while offering tailored formulations for different application scenarios.

As an international plastic raw material trader, we comprehensively supply the HiFill® PPSU series of products, helping purchasers quickly find the most suitable material solutions.

01 | Common advantages of the HiFill® PPSU series

Stable flame retardant performance: The entire series meets the UL94 V-0 flame retardant grade and complies with international safety standards.

High mechanical strength: Excellent tensile strength (>60 MPa), flexural strength (85-109 MPa), and flexural modulus as high as 2450 MPa.

Heat Deflection: HDT values of 207–220°C ensure stability in high-temperature applications.

Dimensional & Electrical Reliability: With water absorption rates of only 0.3–0.37% and volume resistivity at 1E15 Ω·cm, the material suits electrical housings and precision parts.

Impact Performance: Izod impact strength can reach 690 J/m, covering applications where toughness is critical.

02 | Model Comparison Table

| รุ่นสินค้า | สี | Filler | Flexural Strength (MPa) | Flexural Modulus (MPa) | Notched Impact (J/m) | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Water Absorption (%) | Rockwell Hardness R | Remarks |

| PPSU 4000 BK | Black | ไม่มี | 88.9 | 2450 | 590 | 69.6 | 207 | 0.37 | 120 | Standard black flame-retardant grade |

| PPSU HF NAT | Natural (optional) | ไม่มี | 85.5 | 2410 | 590 | 68.9 | 207 | 0.37 | 120 | High-flow, natural color optional |

| PPSU 4000 NAT | Natural (optional) | ไม่มี | 88.9 | 2450 | 590 | 69.6 | 207 | 0.37 | 120 | Standard natural grade |

| PPSU GY061 | Gray (optional) | ไม่มี | 88.9 | 2450 | 690 | 69.6 | 207 | 1.1 | 120 | Enhanced impact resistance, suitable for high-impact applications |

| PPSU TL10 | Optional | 10% PTFE | 84.1 | 2410 | 480 | 63.4 | 207 | 1.1 | 120 | Low-friction, wear-resistant filled type, ideal for sliding components |

| PPSU A1 0200 B LE | เป็นธรรมชาติ | ไม่มี | 109 | 30300 | 64.1 | 62.1 | 220 | 0.3 | 120 | High modulus, high strength, suitable for structural parts |

Table Notes: Buyers can quickly identify the appropriate model based on differences in flexural strength, modulus, notched impact strength, and filler type.

03 | HiFill® PPSU Series Performance Comparison

| แบบอย่าง | ความแข็งแรงทางกล | Heat Resistance | Toughness / Impact | Processing Flowability | Wear Resistance | การใช้งานทั่วไป |

| PPSU 4000 BK / NAT | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | General-purpose: Medical devices, electronic & electrical parts |

| PPSU HF NAT | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | High flowability: Complex molds, large injection-molded parts |

| PPSU GY061 | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★☆☆ | High toughness: Aerospace parts, medical housings |

| PPSU TL10 (PTFE 10%) | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ | Wear-resistant: Sliding components, mechanical parts |

| PPSU A1 0200 B LE | ★★★★★ | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ | High modulus: Aerospace, defense precision components |

Quick Selection Guide

・PPSU HF NAT → For thin-wall or complex parts where flowability matters most.

・PPSU GY061 → For high-impact applications such as connectors or brackets.

・PPSU TL10 → PTFE-filled (10%) grade for sliding parts requiring wear resistance.

・PPSU A1 0200 B LE → For applications demanding high modulus and strength.

・PPSU 4000 BK / NAT → A versatile option balancing mechanical strength and flame retardancy.

04 | Application Recommendations

Medical Devices:

-PPSU 4000 NAT and HF NAT are suitable for sterilizable parts such as syringe components and ventilator housings.

Electrical & Electronics:

-PPSU 4000 BK is flame-retardant and used in switchgear, connectors, and plug housings.

High-Impact Parts:

-PPSU GY061 offers improved toughness, fitting for load-bearing connectors and structural supports.

Friction & Wear:

-PPSU TL10, with PTFE reinforcement, reduces wear in sliding elements like pump seals or valve seats.

Structural Strength:

-PPSU A1 0200 B LE is chosen when rigidity and long-term strength are priorities.

05 | Juyuan’s Trading Advantages

Full Model Coverage – Direct supply of the entire HiFill® PPSU portfolio.

Logistics Assurance – Reliable international shipping, including fast routes via Ningbo Port.

Technical Guidance – Assistance in material selection, processing, and design adaptation.

Global Trade Experience – Years of supplying engineering plastics to clients across multiple regions.

06 | FAQs

Q1: Can HiFill® PPSU be injection molded into complex shapes?

Yes. The series is designed for standard injection molding. HF NAT, in particular, provides high flow for thin-wall parts.

Q2: Which grades withstand autoclaving?

PPSU 4000 series and A1 0200 B LE are suited for repeated steam sterilization.

Q3: What differentiates TL10 from standard PPSU?

TL10 integrates 10% PTFE filler, which lowers friction and extends life in sliding or rotating applications.

07 | Conclusion

TECHMER PM’s HiFill® PPSU series covers a wide spectrum of industrial and medical requirements, from flame retardancy to high impact resistance and wear performance. Partnering with Juyuan means more than accessing a reliable PPSU supply—it ensures professional technical support, optimized procurement, and global logistics for every project.

【ข้อแนะนำที่เกี่ยวข้อง】

Global Plastic Raw Material Market Insights H2 2025 เรียนรู้เพิ่มเติม>

RADEL® PPSU | High Tough Plastics for Medical & Aerospace เรียนรู้เพิ่มเติม>

RADEL R5500 vs R4400: PPSU Selection & Comparison Guide เรียนรู้เพิ่มเติม>