ПРОДУКТЫ

PSU GF20 | 20% Glass Fiber Reinforced Polysulfone for Medical

Структура продукта

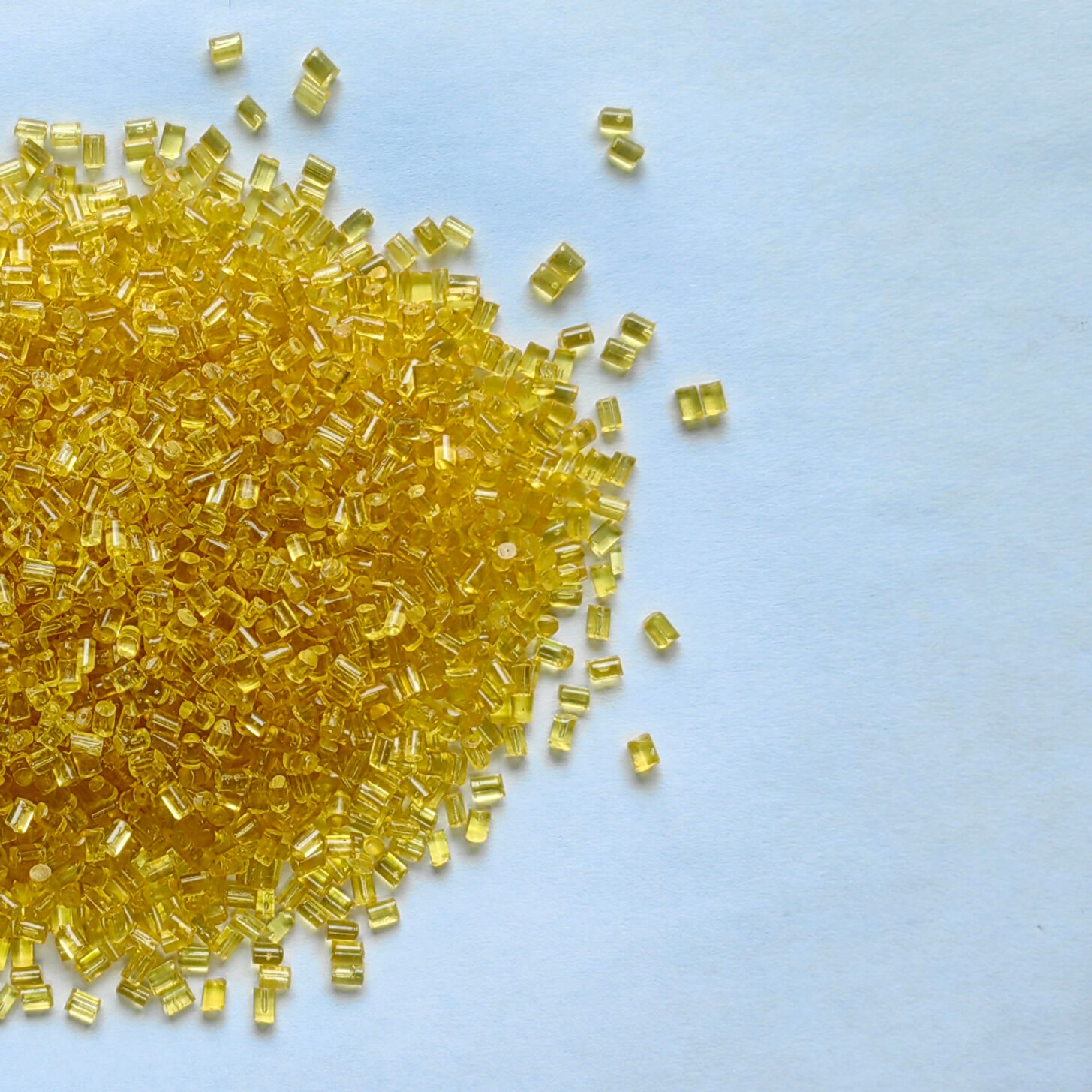

What is PSU GF20

PSU GF20 is an engineering plastic pellet reinforced with 20% glass fiber based on polysulfone (PSU). It combines the heat, hydrolysis, and chemical resistance of PSU with enhanced strength, rigidity, and dimensional stability due to the glass fiber filling. PSU GF20 is an ideal material choice for applications requiring high reliability and long life.

01 | Key Performance Characteristics of PSU GF20

Reinforcement: 20% glass fiber increases the material's strength and modulus, reduces shrinkage (to only 0.2%), and effectively minimizes product warpage.

Mechanical Properties:

・Tensile Strength: 112 MPa

・Flexural Strength: 153 MPa

・Flexural Modulus: 5860 MPa

・Notched Impact Strength: 80.1 J/m

Тепловые свойства:

・Heat Deflection Temperature (HDT): 182°C (1.80 MPa)

・Coefficient of Linear Expansion: 3.06E-3 cm/cm/°C, excellent dimensional stability

Физические свойства:

・Water Absorption: 0.24% (23°C, 24 hours)

・Specific Gravity: 1.38 g/cm³, moderate density

Electrical Properties:

・Volume Resistivity: 1E16 Ω·cm

・Dielectric Strength: 16.9 kV/mm

Hardness: Rockwell R 123, excellent surface wear resistance

PSU GF20 Data Sheet

| Механическое поведение | Состояние | Стандартный | Ценить | Единица | |||

| Удлинение | 23℃ | АСТМ Д638 | 7 | % | |||

| Прочность на изгиб | Выход 23°C | АСТМ Д790 | 153 | МПа | |||

| Модуль упругости при изгибе | 23℃ | АСТМ Д790 | 5860 | МПа | |||

| Удар по Изоду | 23℃ | АСТМ Д256 | 80.1 | Дж/м | |||

| Предел прочности | Выход 23°C | АСТМ Д638 | 112 | МПа | |||

| Термальный | Состояние | Стандартный | Ценить | Единица | |||

| HDT | Неотожженный 1,80МПа | АСТМ Д648 | 182 | ℃ | |||

| КЛЕ | xFlow | АСТМ Д696 | 3.06E-3 | см/см/℃ | |||

| Физическая собственность | Состояние | Стандартный | Ценить | Единица | |||

| Поглощение воды | 23℃ 24 часа | АСТМ Д570 | 0.24 | % | |||

| Усадка | Поток | ASTM D995 | 0.2 | % | |||

| Плотность | АСТМ Д792 | 1.38 | г/см³ | ||||

| Электрические свойства | Состояние | Стандартный | Ценить | Единица | |||

| Объемное сопротивление | АСТМ Д257 | 1E16 | Ом.см | ||||

| Диэлектрическая прочность | АСТМ Д149 | 16.9 | КВ/мм | ||||

| Твердость | Состояние | Стандартный | Ценить | Единица | |||

| Твердость по Роквеллу | R(Масштаб) | АСТМ Д785 | 123 | ||||

02 | Process and Processing Compatibility

Particle Form: Easy to store and transport, suitable for injection molding.

Processing Advantages: Glass fiber reinforcement reduces shrinkage and deformation, ensuring part precision; excellent thermal stability makes it suitable for complex mold designs.

Notes: When processing under high-temperature conditions, barrel temperature must be controlled to avoid degradation; the impact of glass fiber orientation on mechanical properties must be considered during mold design.

03 | Typical Applications

Automotive Parts

・Lighting brackets, instrument panels, and engine compartment structural components

・Parts requiring heat resistance, oil resistance, and high strength

Medical Devices

・Can be used for some re-sterilizable medical device housings and pump and valve accessories

・Balanced electrical insulation and hydrolysis resistance

Electronic and Electrical

・Insulated terminals, relay housings, and printed circuit board substrates

・Meets requirements for high dielectric strength and dimensional stability

Industrial Equipment

・Gears, pump bodies, and mechanical components

・Long-term use requiring wear resistance and high temperature resistance

04 | Industry Comparisons and Trends

Compared to Unreinforced PSU: PSU GF20 offers significantly improved rigidity, strength, and dimensional stability, making it more suitable for structural parts, while unreinforced PSU is more suitable for products requiring toughness and transparency.

Compared to Other Engineering Plastics:

・Compared to PC: Higher heat resistance and better chemical resistance.

・Compared to PPS: Slightly lower heat resistance, but better toughness.

・Compared to PEEK: Lower performance, but more cost-effective, suitable for mid- to high-end applications.

Industry Trends: With the advancement of lightweighting, electrification, and precision medical equipment, demand for reinforced PSU is growing, and psu gf20 has become a common material.

05 | Purchasing Key Points

Performance Matching: Choose whether glass fiber reinforcement is required based on the application to avoid sacrificing toughness due to excessive rigidity.

Processing Conditions: Ensure that the equipment is capable of high-temperature molding to avoid material degradation that may affect performance.

Certification Requirements: For applications in the medical and electrical fields, pay attention to FDA, UL, RoHS, and other certifications.

Supply Stability: Select a trader with extensive channels and stable supply to ensure long-term supply and after-sales support.

06 | Similar recommendations

| Производитель | Модель продукта | Удельный вес | Предел прочности | Удлинение | Усадка | Температура теплового прогиба | Твердость по Роквеллу | Notched Izod Impact | Модуль упругости при изгибе | Coefficient of Linear Expansion | Прочность на изгиб |

| Сольвей | GF-110 NT LF | 1.33 g/cm³ | 77.9 MPa | 4% | 0.40% | 179 ℃ | – | 48 J/m | 3790 MPa | – | 128 MPa |

| Tekoma | PSU GF30 | 1.49 g/cm³ | 131 MPa | 2.00% | 0.20% | 182 ℃ | 123 | 80 J/m | 8270 MPa | 3.1E-5 cm/cm/℃ | 172 MPa |

| Tekoma | PSU 1700 LE NAT | 1.47 g/cm³ | 55.2 MPa | 1.00% | 0.50% | 174 ℃ | 120 | 32 J/m | 3960 MPa | 7.2E-5 cm/cm/℃ | 103 MPa |

| Tekoma | PSU LE NAT | 1.24 g/cm³ | 74.5 MPa | 5.00% | 0.60% | 182 ℃ | 120 | 53 J/m | 2590 MPa | 7.2E-5 cm/cm/℃ | 110 МПа |

| Tekoma | PSU GF10 | 1.31 g/cm³ | 86.2 MPa | 7.00% | 0.40% | 183 ℃ | 123 | 59 J/m | 4140 MPa | 3.1E-5 cm/cm/℃ | 139 MPa |

| Tekoma | PSU CR X | 1.24 g/cm³ | 88.3 MPa | 5% | – | 79.4 ℃ | 120 | 90.8 J/m | 2590 MPa | 7.2E-3 cm/cm/℃ | 110 МПа |

| Tekoma | PSU GF20 BK | 1.38 g/cm³ | 112 MPa | 7.00% | 0.20% | 182 ℃ | 123 | 80 J/m | 5860 MPa | 3.1E-5 cm/cm/℃ | 153 MPa |

| Tekoma | PSU 0147 TC-1 | 1.47 g/cm³ | 55.2 MPa | 1.00% | 0.50% | 182 ℃ | 120 | 32 J/m | 3960 MPa | 7.2E-5 cm/cm/℃ | 103 MPa |

| Tekoma | PSU LE WT | 1.24 g/cm³ | 74.5 MPa | 5.00% | 0.60% | 182 ℃ | – | 53 J/m | 2590 MPa | 7.2E-5 cm/cm/℃ | 110 МПа |

07 | Frequently Asked Questions (FAQ)

Q1: Can psu gf20 withstand long-term high temperatures?

A1: Its heat deflection temperature is 182°C, making it suitable for long-term use in high-temperature environments, but attention should be paid to load conditions.

Q2: Is psu gf20 suitable for electrical applications?

A2: Yes. Its volume resistivity reaches 1E16 Ω·cm and its dielectric strength is 16.9 kV/mm, making it suitable for insulating components.

Q3: How does it compare to PPS and PEEK?

A3: PSU GF20 is superior to general engineering plastics in heat and chemical resistance. While not as good as PEEK, it offers a cost advantage.

Q4: Is processing difficult?

A4: The main challenge is controlling the processing temperature to avoid molecular degradation; the glass fiber orientation affects the strength distribution of the product.

08 | Why choose Juyuan as your PSU supplier?

As a supplier with 24 years of experience in international plastic raw material trading, Juyuan is committed to providing customers with:

・Multi-channel stable supply: Ensuring the continuous availability of engineering plastics such as psu gf20

・Material selection and technical support: Helping customers select the appropriate grade based on their application

・Industry trend insights: Providing procurement references and market analysis

・Flexible trading and logistics solutions: Supporting fast delivery for customers worldwide

Choosing Juyuan means not only obtaining materials, but also receiving one-stop plastic raw material trading services.

【Связанные рекомендации】

Medical-Grade PSU P-1700 LCD | Medical-Grade Udel® PSU Узнать больше>

PSU GX07409H for Medical Care Products | PSU Supplier Guide Узнать больше>

Guide to Plastics in Electronics: 2025 Selection & Compliance of Electronic Plastic Resins Узнать больше>