ПРОДУКТЫ

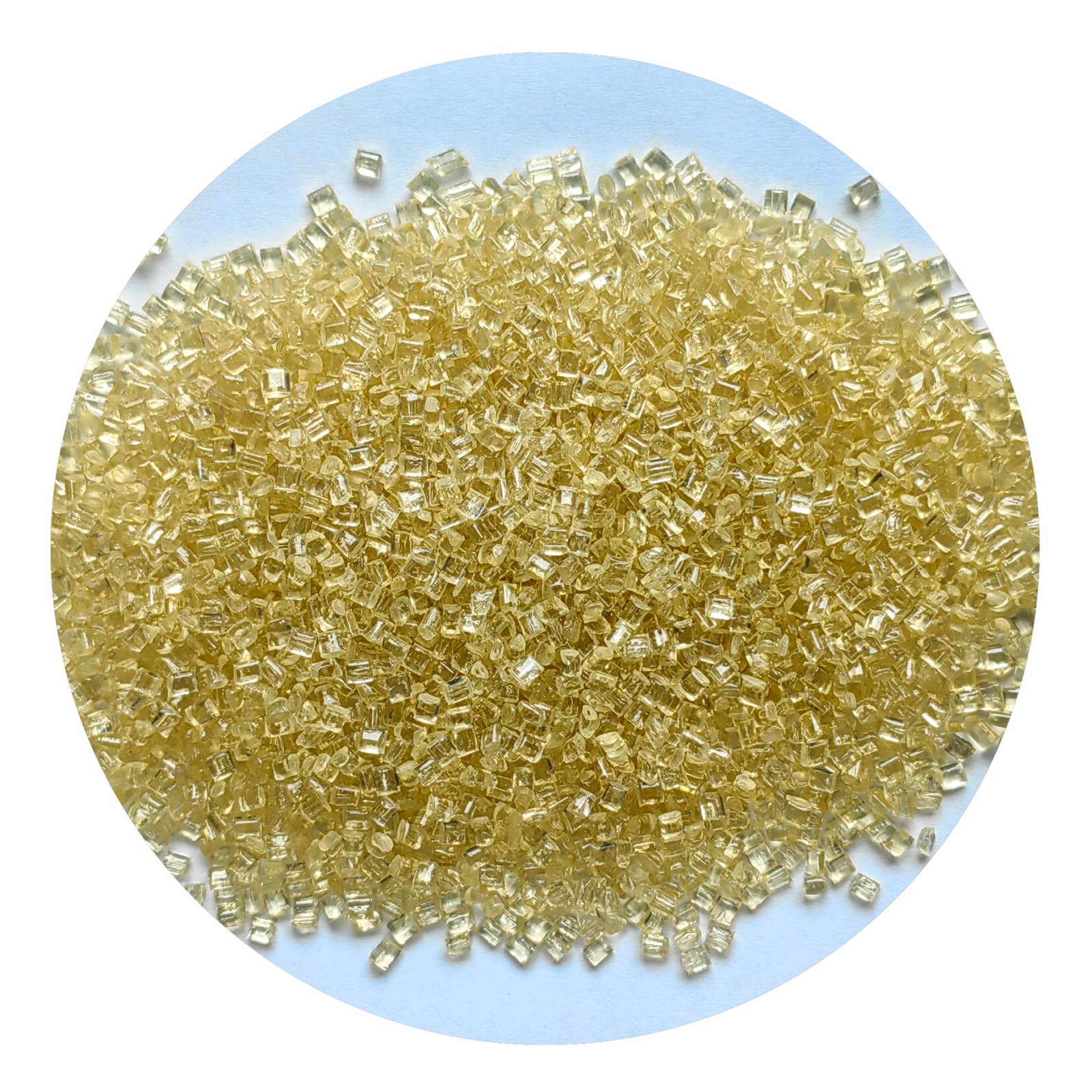

PSU G1000 Unfilled Flame-Retardant Injection Molding PSU Material

Структура продукта

01 | Why do purchasers pay attention to PSU материал - G1000?

In the market of transparent engineering plastics, common choices include PC, PPSU and different grades of psu material. However, Saudi Basic's PSU G1000 stands out at a unique balance point:

・Balancing transparency and flame retardancy - Although PC is transparent, its flame retardancy is limited. PPSU has strong flame retardancy, but it is expensive and has more stringent processing requirements. The PSU G1000 precisely fills the market gap with its V-0 grade flame retardancy and excellent light transmittance.

・The controllability of cost and process - flame retardancy can be achieved without additional filling, which means simpler processing, longer mold life, and overall cost control.

・Supply flexibility - The market demand for PSU G1000 continues to rise. What purchasers care about is not only performance but also whether they can obtain it stably. Juyuan supplies materials through multiple channels, including original manufacturers and other global sources, helping customers maintain a sustainable supply even when supply and demand fluctuate.

02 | Technical features are transformed into procurement value

Simple figures of tensile strength and flexural modulus have limited significance for designers or purchasing managers. The true value lies in:

・Reliable safety: Achieves V-0 under UL94 4.5mm conditions, ensuring fire protection requirements for electrical enclosures and medical components.

・Structural accuracy: A shrinkage rate of 0.4 to 0.7% enables complex parts to be formed without significant secondary corrections.

・Heat resistance and durability: It remains stable in shape at 170℃ and can replace some metal parts, reducing weight and cost.

When purchasers choose psu material, the most concerned issue is whether it can simultaneously meet regulations, safety, craftsmanship and cost, and PSU G1000 provides the answer.

03 | Application scenario: Who is using PSU G1000?

Medical equipment manufacturer: A transparent shell that can withstand steam sterilization is needed. The cost of using PPSU is too high, while PSU G1000 is a better choice in terms of cost performance.

Electrical and electronic enterprises: Applied in relays, switches, and transparent protective covers, flame retardant up to standard, avoiding fire risks.

Transportation and aviation accessories: Replace some PC materials to enhance flame retardant safety while maintaining lightweight.

Drinking water and food contact parts: Low water absorption rate and chemical stability make them less likely to fail when used for a long time in fluid systems.

The message conveyed behind these applications is clear: PSU G1000 is a universal flame-retardant transparent solution for cross-industry procurement.

04 | PSU G1000 Data Sheet

| Механическое поведение | Состояние | Стандартный | Ценить | Единица | |||

| Удлинение | Производительность 50мм/мин | ИСО 527 | 5.9 | % | |||

| Прочность на изгиб | Yield 2.0mm/min | ИСО 178 | 115 | МПа | |||

| Модуль упругости при изгибе | 2,0 мм/мин | ИСО 178 | 2500 | МПа | |||

| Изод Не-надрез Удар | 23℃ 4.00mm | ИСО 180 | Примечание: | кДж/м² | |||

| Удар по Изоду | 23℃ 4.00mm | ИСО 180 | 6 | кДж/м² | |||

| Предел прочности | Производительность 50мм/мин | ИСО 527 | 76 | МПа | |||

| Предел прочности | Разрыв 50мм/мин | ИСО 527 | 60 | МПа | |||

| Модуль упругости | 1,0 мм/мин | ИСО 527 | 2500 | МПа | |||

| Термальный | Состояние | Стандартный | Ценить | Единица | |||

| HDT | 0.45MPa 4.00mm | ИСО 75 | 183 | ℃ | |||

| HDT | 1.80MPa 4.00mm | ИСО 75 | 170 | ℃ | |||

| КЛЕ | Flow 23~60℃ | ИСО 11359 | 6.1E-5 | см/см/℃ | |||

| КЛЕ | xFlow 23~60℃ | ИСО 11359 | 6.2E-5 | см/см/℃ | |||

| Физическая собственность | Состояние | Стандартный | Ценить | Единица | |||

| Поглощение воды | 23℃ 24 часа | ИСО 62 | 0.4 | % | |||

| Усадка | Поток | ВНУТРЕННИЙ МЕТОД | 0.4~0.7 | % | |||

| Плотность | ИСО 1183 | 1.24 | г/см³ | ||||

| Воспламеняемость | Состояние | Стандартный | Ценить | Единица | |||

| Рейтинг пламени | 4.5mm | UL94 | В-0 | ||||

| Рейтинг пламени | 1,5 мм | UL94 | полупансион | ||||

05 | Process adaptability

PSU G1000 is mainly processed by injection molding. Its non-filling property and uniform flow performance make it suitable for:

・Complex and precision parts: Maintain transparency and high dimensional stability.

・Electrical insulation components: Flame retardant safety grade complies with UL standards.

・Medical device components: Heat-resistant, sterilization-resistant, and also possess mechanical strength.

Compared with other psu Materials, the processing window of G1000 is wider, reducing the failure rate in the mold design and production links.

06 | Industry trend: psu material Opportunities Driven by regulations

In the next five years, the requirements for flame retardant safety in the European Union and North America will be further tightened. Compared with traditional PCS, PSU G1000 is more forward-looking in terms of compliance. Compared with PPSU, it is more suitable for bulk purchasing in terms of cost and processability. For international purchasers, laying out PSU G1000 in advance means maintaining a competitive edge in the upgrade of regulations.

07 | Similar recommendations

For purchasers who need a broader selection of psu materials, the following materials deserve attention:

| Производитель | Модель продукта | Description | Удельный вес |

| SABIC | G1000L | Compliance: FDAMaterial Characteristics: UnfilledApplications: Lenses • Medical Care Products | 1.24 g/cm³ |

| SABIC | GX02708H (PDX-G-02708 HC) | Material Characteristics: UnfilledApplications: Medical Care Products | 1.24 g/cm³ |

08 | The role of Juyuan

As Juyuan, which focuses on international plastic raw material trade, our advantages lie in:

Multi-channel acquisition capability: Not only can the original factory PSU G1000 be provided, but also the same-grade material sources from different channels can be integrated to ensure the flexibility and continuity of procurement.

Customized recommendations: In response to customers' application requirements (transparency, flame retardancy requirements, cost budget), we offer a variety of solutions including PSU G1000, GX02708H, and G1000L.

Technical and selection support: Assist customers in evaluating process compatibility and regulatory compliance, and shorten the cycle from design to mass production.

Against the backdrop of global competition and fluctuations in the supply chain, Juyuan does not rely on a single channel. Instead, it adopts a model of diversified supply and professional support to ensure greater certainty for customers when purchasing psu material.

【Связанные рекомендации】

Sultron™ PSU: High-Temperature Polysulfone Material for Engineering Applications Узнать больше>

Enviroplas ENV48-NC570 | Oil Resistance PSU Plastic for Medical Узнать больше>

Automotive Plastic Raw Materials Procurement Guide Узнать больше>