ПРОДУКТЫ

Ketron 1000 PEEK: Food-Contact Grade PEEK for Reliable Sealing

Структура продукта

What is Ketron® 1000 PEEK

In the field of sealing materials, maintaining controlled deformation and stable service life in high-temperature, high-pressure, and chemically resistant environments is a key challenge facing engineers.

Mitsubishi Chemical Ketron® 1000 PEEK, with its food-contact-grade purity, high elongation, and high toughness, provides a reliable solution for precision sealing components. This unfilled, general-purpose PEEK material offers a balance of mechanical strength and flexibility, suitable for long-term operation in demanding conditions.

I. Material Highlights

Food Contact Certification: Meets food, pharmaceutical, and cleanroom equipment safety standards, with a pure material and no risk of filler migration.

High Elongation: Elongation at break reaches 17%, demonstrating excellent ductility and crack resistance.

High Toughness Structure: Maintains a balance of strength and toughness under impact loads or thermal cycling.

General-purpose formulation: Unfilled design adapts to various processing methods (injection molding, extrusion, and machining).

Heat and Chemical Resistance: Can operate continuously at 250°C and is resistant to most organic solvents and steam.

II. Performance Analysis

1. Mechanical Properties - A Balance of Flexibility and Strength

Ketron® 1000 PEEK is an unfilled PEEK system with typical high ductility.

・Tensile Strength: 115 MPa

・Elongation at Break: 17%

・Flexural Strength: 170 MPa

・Flexural Modulus: Approximately 4.3 GPa

・Notched Impact Strength: 3.26 kJ/m²

This combination of properties allows it to effectively absorb stress during continuous deformation or high-pressure assembly and sealing, preventing brittle fracture.

2. Thermal Properties - Long-Term 250°C Withstand

Ketron® 1000 PEEK offers excellent thermal stability:

・Continuous operating temperature up to 250°C for 20,000 hours;

・Melt temperature approximately 340°C;

・Heat Deflection Temperature (1.8 MPa) 160°C.

It maintains shape and rigidity even in high-temperature seals, valve seats, or steam systems.

3. Electrical and Tribological Properties

・Dielectric Constant (1MHz): 3.2

・Volume Resistivity: 1×10¹⁴ Ω·cm

・Dynamic Friction Coefficient: 0.3-0.5

Combined with excellent surface finish and low wear properties, it is suitable for rotating or sliding seals requiring friction stability and fatigue resistance.

4. Ketron® 1000 PEEK Data Sheet

| Механическое поведение | Состояние | Стандартный | Ценить | Единица | |||

| Удлинение | Урожай | ИСО 527 | 5 | % | |||

| Удлинение | Перерыв | ИСО 527 | 17 | % | |||

| Прочность на сдвиг | АСТМ Д732 | 55 | МПа | ||||

| Прочность на сжатие | АСТМ Д695 | 137.93 | МПа | ||||

| Прочность на сжатие | 1% Strain | ИСО 604 | 38 | МПа | |||

| Прочность на сжатие | Штамм 2% | ИСО 604 | 75 | МПа | |||

| Прочность на сжатие | Штамм 5% | ИСО 604 | 140 | МПа | |||

| Прочность на изгиб | ИСО 178 | 170 | МПа | ||||

| Модуль упругости при изгибе | АСТМ Д790 | 4134 | МПа | ||||

| Удар по Изоду | АСТМ Д256 | 3.26 | кДж/м² | ||||

| Предел прочности | ИСО 527 | 115 | МПа | ||||

| Модуль упругости | ИСО 527 | 4300 | МПа | ||||

| Friction Factor | ISO 7148 | 28 | µm/km | ||||

| Коэффициент трения | Динамичный | ISO 7148 | 0.3~0.5 | ||||

| Limited PV Value | 0.1 m/s | ВНУТРЕННИЙ МЕТОД | 0.21 | MPa・m/s | |||

| Limited PV Value | 100fpm | QTM 55007 | 8500 | ft·lb/in²·min | |||

| Ударная вязкость по Шарпи без надреза | ИСО 179 | Примечание: | кДж/м² | ||||

| Удар по Шарпи | ИСО 179 | 3.5 | кДж/м² | ||||

| Термальный | Состояние | Стандартный | Ценить | Единица | |||

| Operating Temperature | Continuous 20000hr | ВНУТРЕННИЙ МЕТОД | 250 | °С | |||

| Operating Temperature | MIN | ВНУТРЕННИЙ МЕТОД | -50.0 | °С | |||

| Коэффициент теплопроводности | 23°С | ВНУТРЕННИЙ МЕТОД | 0.25 | Вт/(м·К) | |||

| HDT | 1,8 МПа | ИСО 75 | 160 | °С | |||

| Температура плавления | ДСК 10°C/мин | ИСО 11357 | 340 | °С | |||

| КЛЕ | -40.0~150°C TMA | ASTM E831 | 2.6E-5 | см/см/°С | |||

| КЛЕ | 23~100°C | ВНУТРЕННИЙ МЕТОД | 5.5E-5 | см/см/°С | |||

| КЛЕ | 150°C | ВНУТРЕННИЙ МЕТОД | 1.3E-4 | см/см/°С | |||

| Физическая собственность | Состояние | Стандартный | Ценить | Единица | |||

| Поглощение воды | 23°C 饱和 Water | ВНУТРЕННИЙ МЕТОД | 0.45 | % | |||

| Поглощение воды | 23°C 24hr Water | ИСО 62 | 0.06 | % | |||

| Плотность | ИСО 1183 | 1.31 | г/см³ | ||||

| Электрические свойства | Состояние | Стандартный | Ценить | Единица | |||

| Диэлектрическая постоянная | 1МГц | МЭК 62631-2-1 | 3.20 | ||||

| Объемное сопротивление | МЭК 62631 | 1E+14 | Ом.см | ||||

| Диэлектрическая прочность | МЭК 60243 | 24 | КВ/мм | ||||

| Коэффициент рассеивания | 1МГц | МЭК 62631-2-1 | 0.0020 | ||||

| Поверхностное сопротивление | ANSI/ESD STM11.11 | 1E+13 | Ом | ||||

| Твердость | Состояние | Стандартный | Ценить | Единица | |||

| Твердость по Роквеллу | М(Масштаб) | ИСО 2039 | 105 | ||||

| Твердость по Роквеллу | R(Масштаб) | ASTM D2240 | 126 | ||||

| Воспламеняемость | Состояние | Стандартный | Ценить | Единица | |||

| Limited Oxygen Index | ИСО 4589 | 35 | % | ||||

| Рейтинг пламени | Full Color 3.00mm | UL94 | В-0 | ||||

III. Application and Process Compatibility

1. Processing Characteristics

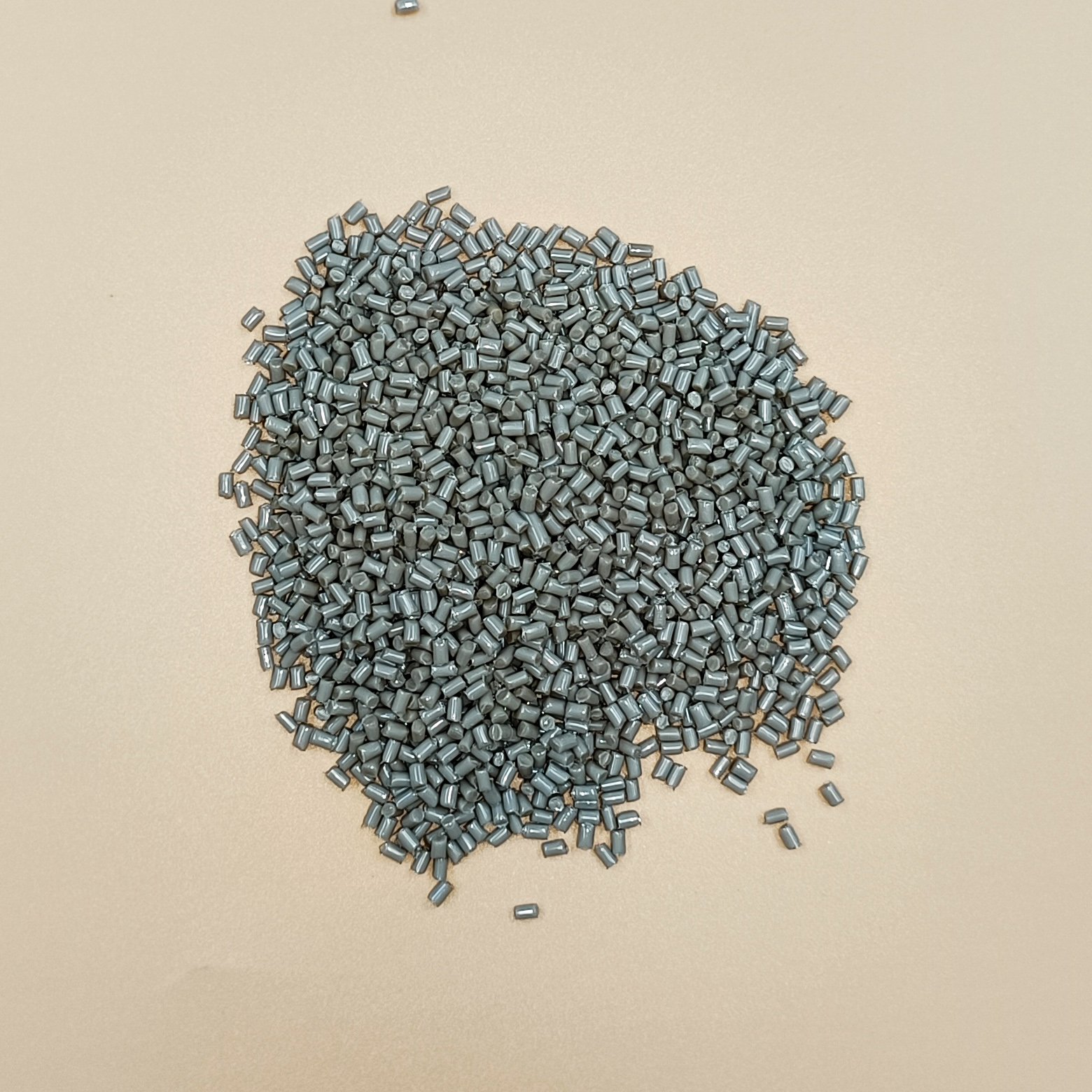

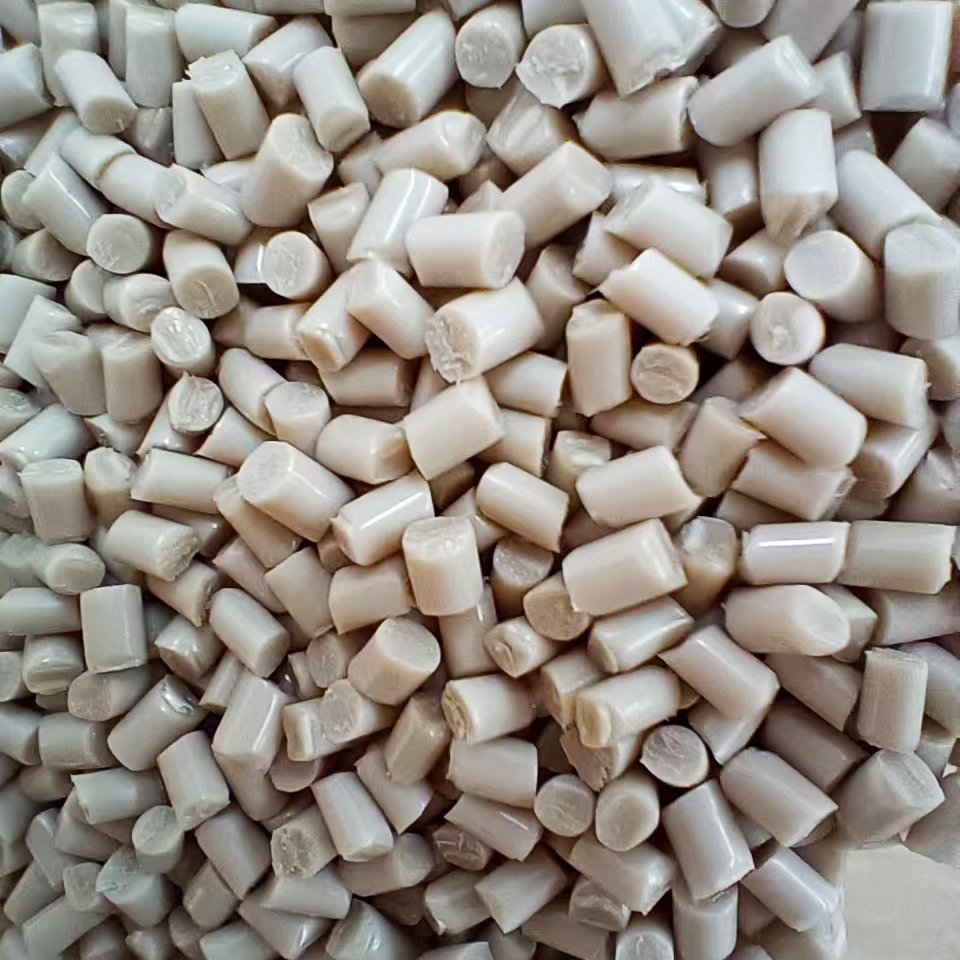

Ketron® 1000 PEEK pellets offer a combination of flowability, toughness, and dimensional stability, making them suitable for injection molding, extrusion, and precision machining.

The unfilled system ensures more uniform melt flow, resulting in smooth surfaces and balanced stress distribution after molding, making the molded parts less susceptible to cracking or warping.

The low water absorption (24-hour water absorption of only 0.06%) ensures dimensional accuracy and sealing reliability in humid or high-temperature environments.

Therefore, it is often selected for components requiring long-term airtightness and chemical resistance.

💡 Processing Recommendation: Maintaining mold temperature between 170–200°C improves part crystallinity and mechanical strength, making it suitable for molding demanding sealing components.

2. Typical Applications

Ketron® 1000 PEEK is widely used in a variety of high-end manufacturing fields, particularly excelling in the following applications:

・Hydraulic and pneumatic system seals – maintain stable dimensions and low wear rates even after long-term operation in high-pressure fluids.

・Valve seats and pump bushings for chemical equipment – exhibit excellent chemical inertness and resistance to acid, alkali, and solvent corrosion.

・Food processing machinery contact components – certified for food contact, ensuring safety and no leaching, meeting hygienic standards.

・Electrical insulation sealing components – combining insulation and heat resistance, suitable for electrical packaging and sensor housings.

With its combination of pure resin, high toughness, and low water absorption, Ketron® 1000 PEEK is an ideal material choice for seals, valve seats, sliding rings, and precision insulation components.

Whether used in food processing machinery, chemical fluid systems, aviation, or clean manufacturing equipment, it achieves a precise balance between heat resistance, wear resistance, and chemical stability.

IV. Industry Value and Advantages

Highly tough structure reduces failure risk.

Seals are less susceptible to crack propagation during installation or under pressure, ensuring a longer lifespan.

Food Contact Safe

The material meets relevant safety standards and can be used in the manufacture of food and pharmaceutical machinery components.

Low friction and fatigue resistance

Maintains smooth surfaces during repeated seal movements, reducing energy consumption and wear.

The unfilled system offers high remachinability.

Easy to turn, drill, and grind, it is suitable for customized seal designs.

V. Recommendations for Similar Applications (Specialized for Seals)

The following section provides recommendations for similar applications, allowing users to compare and choose alternative models.

| Производитель | Модель продукта | Description | Удельный вес | Предел прочности | Удлинение | Усадка | Температура плавления | Модуль упругости | Температура теплового прогиба | Твердость по Роквеллу | Izod Notched Impact | Модуль упругости при изгибе | Coefficient of Linear Expansion | Прочность на изгиб | Value Summary |

| TECHMER PM | PEEK GF30 HT011A | Material Property: Dimensional Stability Material Application: Sealing Parts | 1.50 g/cm³ | 157 MPa | 3.00% | 0.40% | 342 ℃ | 10,900 MPa | 316 ℃ | 115 | 99 J/m | 8,270 MPa | 2.2E-5 cm/cm/℃ | 217 MPa | Flammability Rating: V-0 Notched Impact: 10.10 kJ/m² Melting Temperature: 342 ℃ |

This material is also used in seals, bearings, and valve seats, allowing for flexible selection based on temperature, media, and cost requirements.

VI. Juyuan Supply and Technical Support

As an international plastic raw material trader with 24 years of industry experience, Juyuan provides a stable supply of Ketron® 1000 PEEK and selection support.

We offer our customers:

・Multi-channel supply and batch traceability;

・Technical consulting and application guidance;

・Customized packaging and international logistics services.

Choose Juyuan to achieve more efficient and stable seal production.

【Связанные рекомендации】

SABIC LGL33 | Plastic PEEK Material for Automotive Engine Hood Узнать больше>

HiFill® 450 A | Medium Flowability PEEK Engineering Plastic Узнать больше>

Comprehensive Classification & Market Applications of Plastic Materials Узнать больше>