Plastic Molding Process

In the world of plastic products, particles are just the beginning. How they are transformed into bags, pipes, automotive parts or medical devices depends on the support of various forming and processing techniques behind them. From traditional craftsmanship to intelligent manufacturing, each approach affects material properties, product quality and even production efficiency. For purchasers of plastic raw material pellets, understanding these processing paths not only helps with material selection but also provides strategic guidance for the development of end products.

This article will systematically sort out several mainstream plastic processing methods and combine them with emerging technological trends to provide you with professional insights and material selection references.

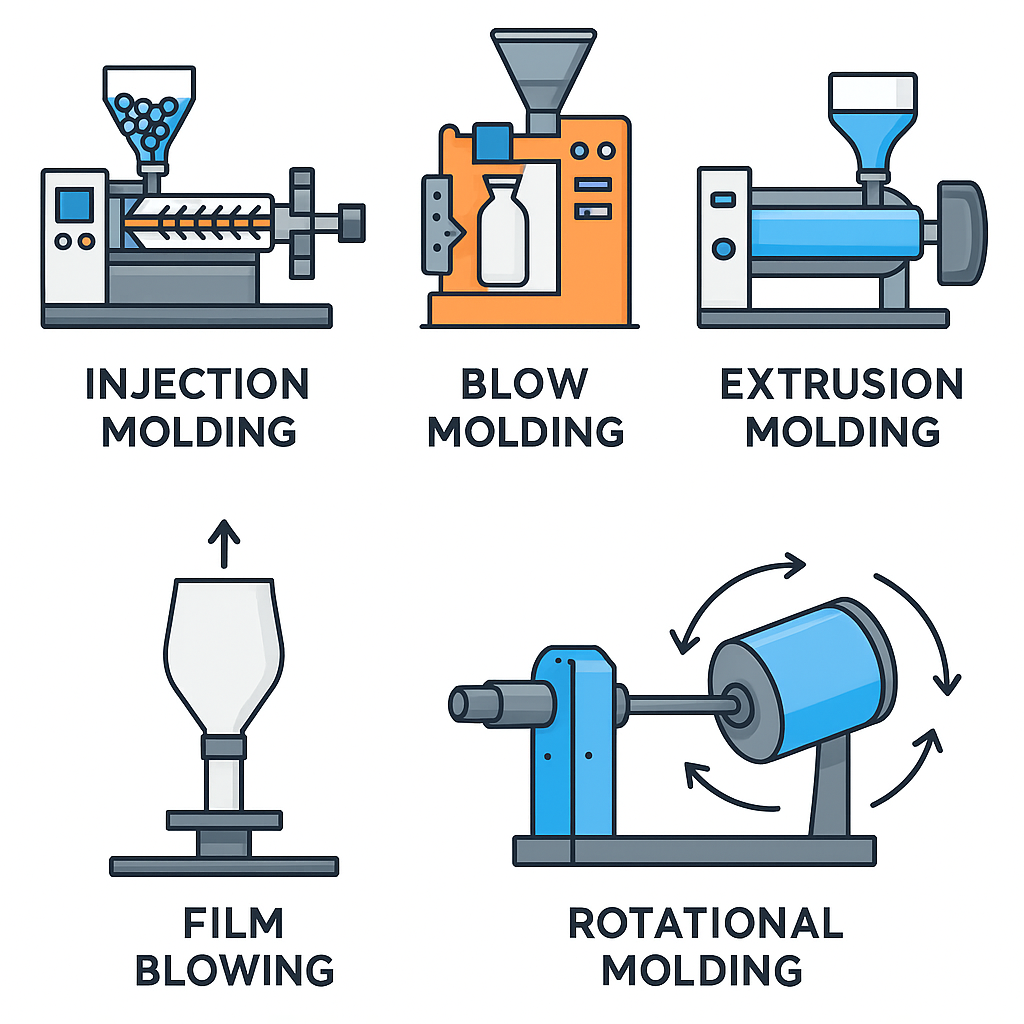

1. Main traditional processing techniques: stable, efficient, and replicable on a large scale

Injection Molding: The main force for efficient mass production

Applicable materials: PP, HDPE (полиэтилен высокой плотности), АБС, ТПУ, ПБТ, Пенсильвания, etc

Process description: Molten plastic is injected into the mold, and after cooling and setting, complex-shaped structural components are formed.

Application examples: bottle caps, medical shells, automotive parts, electrical appliance shells

Particle requirements:

・Good fluidity (moderate or high melt index)

・High thermal stability

・Uniform particle size, which is conducive to feeding

Industry trend: Precision injection molding, micro-injection molding, and two-color injection molding are gradually becoming popular, promoting the development of materials towards low warpage and rapid cooling.

Blow Molding: Container manufacturing expert

Applicable materials: ПНД, ПП, ДОМАШНИЙ ПИТОМЕЦ, ЭВОН, etc

Process description: It includes types such as injection blow molding, extrusion blow molding, and hollow blow molding. By using gas to expand the molten material into the mold shape, it is mainly used for hollow products.

Application examples: food bottles, chemical drums, daily chemical packaging, pesticide bottles, fuel tanks, etc

Particle requirements:

・Excellent melt expansion

・Высокая ударная вязкость

・Can support high-capacity production lines (such as double-station or high-speed blow molding)

Industry trend: Lightweight blow-molded bottles, multi-functional co-extrusion, and barrier layer designs (such as EVOH/PA) are gradually becoming mainstream.

Extrusion: The behind-the-scenes protagonist of continuous production

Applicable materials: ПВД, ЛПЭНП, ПНД, ЭВА, PVC, PS, etc

Process description: The plastic is pushed by the screw in the heating cylinder, and the molten plastic is continuously extruded into shape

Application examples: building corner protectors, pipes, cable coverings, films, sealing strips, and special-shaped materials

Particle requirements:

・Stable melt strength

・Melt viscosity matching the downstream traction system

・Free of impurities and with uniform flow

Industry trends: Multi-layer co-extrusion, micro-layer structure, and green halogen-free cable materials are gradually becoming the main themes of the extrusion industry.

Blown Film :Container Manufacturing Expert

Applicable materials: ПВД, ЛПЭНП, ПНД, mPE, etc

Process description: The molten plastic is extruded through a ring-shaped mold and then blown into a film by air flow.

Application examples: express delivery bags, supermarket shopping bags, food packaging films, agricultural films

Particle requirements:

・The melt is uniform and free of impurities

・Good heat sealability and transparency (for packaging)

・High strength and good flexibility (for stretching/winding)

Industry trends: 5-9 layer co-extruded films, functional films (anti-fog, anti-ultraviolet), and all-PE structure recyclable packaging are growing rapidly.

Rotomolding: The "Secret Weapon" for large-volume hollow parts

Applicable materials: ЛПЭНП, ПНД, ЭВА.

Process features: The particles are first heated and melted, then rotated and spread on the inner wall of the mold, and after cooling, they take shape.

Typical applications: water tanks, ice buckets, outdoor seats, traffic cones.

Particle requirements:

・The particle size is strictly controlled (generally requiring powdering or micronization).

・Good thermal stability and cooling shrinkage control

Industry trend: Customized large-sized and small-batch flexible production has driven the demand for LLDPE modified powder in the market.

2. How to Choose the Right Plastic Pellets Based on Processing Method?

Selecting the appropriate plastic raw material pellets not only affects product performance but also has a direct impact on production efficiency and yield. Here are our material selection recommendations based on key manufacturing processes:

| Метод обработки | Key Material Performance Requirements | Recommended Pellet Types |

| Литье под давлением | Moderate melt index, good rigidity | PP, TPU, PBT, ABS |

| Выдувное формование | High impact strength, excellent melt strength | HDPE, PP, multilayer copolymers |

| Extrusion | Stable melt flow, weather resistance | HDPE, PVC, EVA, PE-WAX |

| Film Blowing | Heat sealability, optical clarity | LLDPE, LDPE, mPE, EVA |

| Rotational Molding | Thermal stability, low warpage | LLDPE powder, HDPE pellets |

3. New Propositions on the "Material Selection Logic" in Plastic Granule Processing

As raw material suppliers, we suggest that customers make process connection judgments from the following dimensions when purchasing granules:

・Does the processing technology prefer materials with high fluidity or high melt index?

・Is the product terminal a structural component or flexible packaging?

・Are there any constraints in terms of environmental protection, degradability or recycling?

・Is it suitable for multi-layer co-extrusion, heat sealing, lamination and other composite processing scenarios?

Examples of material adaptation suggestions:

・ЛПЭНП vs ПВД: LLDPE is suitable for stretch films or heavy-duty packaging bags with higher requirements for strength and tensile performance, while LDPE is applicable to traditional films due to its excellent processability.

・ТПУ vs PVC: TPU is more environmentally friendly and has stronger elasticity, making it suitable for high-end sports goods or medical devices. PVC has a cost advantage and is suitable for traditional bulk applications such as cables, shoe soles, and transparent films.

・Engineering plastics such as PBT, Пенсильвания и ПОМ are often used in injection molded parts, high-temperature resistant electrical appliances, gears and other medium and high-end structural components.

4. Emerging Processing Trends: The Two-way Advancement of Technology and Environmental Protection

With the improvement of manufacturing automation, environmental protection regulations and functional requirements, a new generation of plastic particle processing technology is gradually emerging:

Multilayer Cast Film

・It is commonly used in LLDPE and mPE materials. The "lightweight + functional layer integration" of packaging structures is a currently popular direction.

・Advantages: It can precisely control the thickness of each layer, achieving an integrated heat-sealing property, barrier property and printability.

Laser engraving and digital micro-foaming

・Materials such as TPU, EVA, and PA are suitable for laser engraving/fine cutting or physical foaming processes and have been widely used in sports shoe soles, functional clothing accessories, etc.

・Trend highlights: Low energy consumption, high precision, and adaptability to sustainable manufacturing scenarios.

High Transparency Injection Pull-Blow Integrated (ISBM)

・The ISBM process combines injection molding, stretching and blow molding to complete the manufacturing of PET bottle bodies in one go.

・Advantages: Enhances transparency and mechanical properties, suitable for high-end packaging of beverages and medicines.

High-speed 3D printing (FDM/FFF) and hot melt Pellet Extrusion

・The new type of 3D printing equipment can now directly use plastic pellets instead of Filament, reducing costs and enhancing material freedom.

・Material trend: Direct printing of PA, TPU, PLA and ABS particles is gradually maturing.

5. Future Trends in Plastic Processing: Synergistic Upgrading of Materials and Processes

Material reform driven by environmental protection regulations

・The material needs to support the strategy of "thinning without reducing strength"

・"Pure particles" without slippage agents or opening agents are favored

・Single structures (such as PE-PE) support recyclability and reuse

Efficient processing has become the core of equipment upgrading.

・The particles need to be compatible with high-speed blown film and injection molding equipment

・The material needs to have a wider processing window and reduce the risk of thermal decomposition

The growth of functional demands drives multi-layer composite materials:

・Co-extrusion technology requires that raw materials be divided layer by layer (such as anti-scratch on the outer layer/heat sealing on the inner layer)

・Materials like EVA, mPE, metallocene PE and EVOH are gradually becoming the core material combinations

6. Conclusion: We not only sell raw materials, but also are your partner in upgrading your craftsmanship

As a trader of plastic raw material pellets, we are well aware that "using the wrong raw materials is more fatal than using expensive ones." We offer:

・Particles of various specifications, fluidity and transparency are available for selection

・Technical matching support for different processes

・Selection of sustainable development Materials (ISCC certification, Green Label)

・Free sample testing and process optimization suggestions

Behind each of your forming processes, there needs to be a partner who understands materials better.

Welcome to contact us to obtain plastic pellet solutions that match the requirements of your equipment and products.