ПРОДУКТЫ

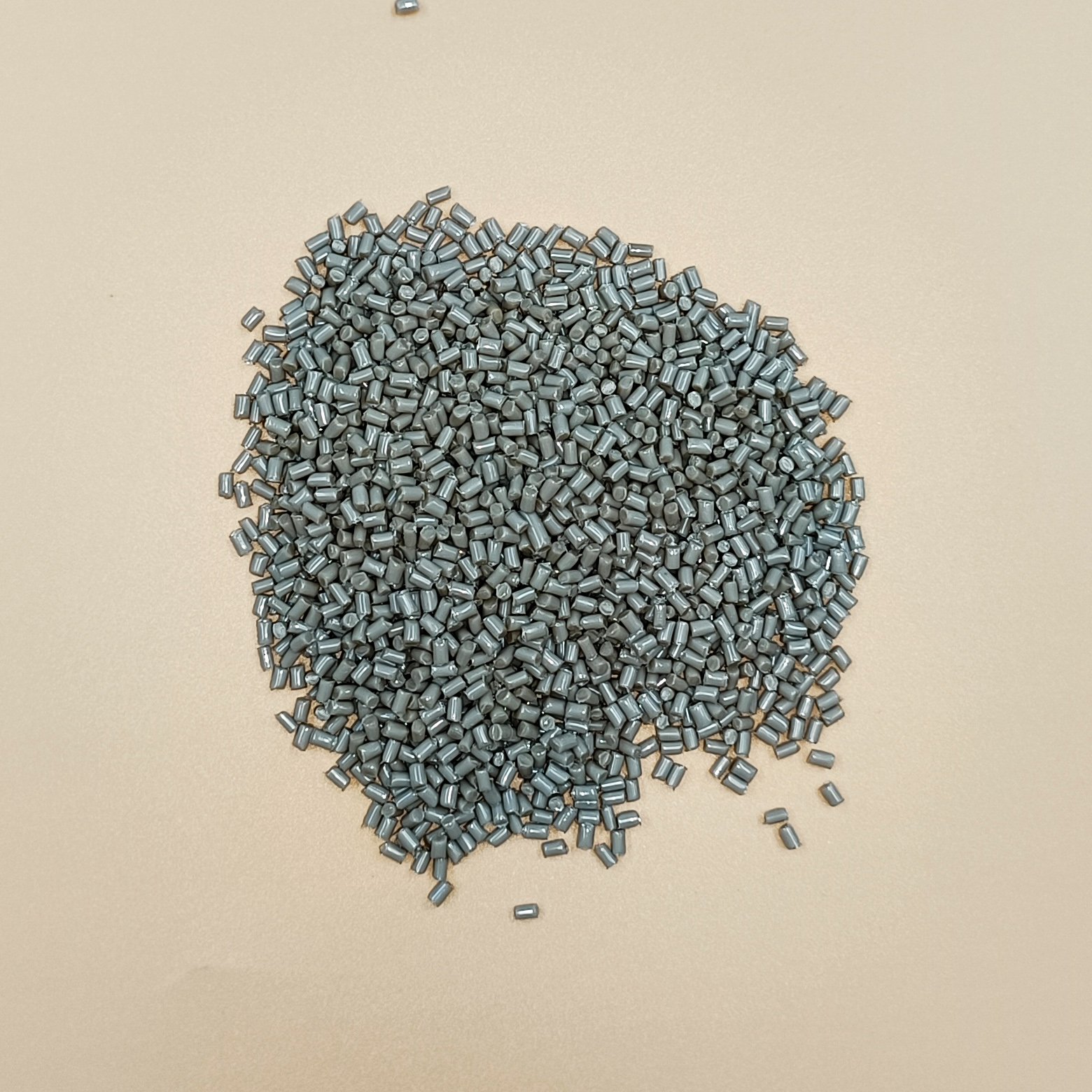

PEEK TK4600 – High-Rigidity FR PEEK Pellets

Структура продукта

What are PEEK Pellets - TK4600

PEEK TK4600 is a flame-retardant PEEK pellets developed by Sumitomo Chemical, featuring an inorganic filling system and excellent thermal stability as its core characteristics. This material, while balancing high

Its particle fluidity is uniform and stable, and it can be adapted to various molding methods, including injection molding, extrusion, compression molding and CNC machining.

Thanks to the thermal stability and low shrinkage characteristics of the material, the dimensional accuracy and repeatability of the mold parts are extremely high. Even in high-temperature and high-pressure environments, the stability of the product's geometric shape can be maintained.

Meanwhile, PEEK pellets releases less gas during processing, causes less mold contamination, greatly improves production efficiency and reduces maintenance costs.

For batch manufacturing enterprises, this means a lower defect rate and higher consistency of good products.

05 | Innovation and Industry Competitive Advantage

The birth of PEEK TK4600 not only optimizes the material's performance but also demonstrates Sumitomo Chemical's leading strength in polymer structure design and flame retardant system innovation:

・Inorganic filling technology - while maintaining light weight, it significantly enhances structural rigidity and wear resistance;

・Intrinsic flame retardant system - can reach UL94 V-0 standard without the addition of halogen, in line with international environmental protection trends;

・Low water absorption and high insulation performance - ensuring electrical safety and long-term dimensional stability;

・Outstanding thermal cycling durability - no significant performance degradation after multiple heating and cooling cycles, ensuring a service life far exceeding that of conventional plastics.

These innovations have made the TK4600 a rare category in the high-end market, especially favored by the manufacturing industries in Europe, America, Japan and South Korea.

06 | Customer Feedback: The trusted choice of global manufacturers

Several international customers have reported that PEEK TK4600 has demonstrated in practical applications:

・Higher mold replication accuracy, reducing later debugging;

・Excellent mechanical strength retention rate at high temperatures;

・The friction and wear are extremely low under long-term operation.

・It can work stably for a long time in electrical components without carbonization or deformation.

・When combined with metal or other engineering plastic parts for processing, the dimensional matching degree is high.

This means that PEEK TK4600 is not merely a material, but also an "added bonus" for production reliability and brand reputation.

07 | Frequently Asked Questions (FAQ)

Q1: What are the differences between PEEK TK4600 and ordinary PEEK?

A: TK4600 is an inorganic-filled flame-retardant PEEK, featuring higher rigidity, thermal stability and flame retardancy. It is suitable for high-temperature electrical structural components and mechanical load parts.

Q2: Is this material suitable for high-precision processing?

A: It's very suitable. Its low shrinkage rate and excellent dimensional stability make it perform extremely stably in CNC or mold injection.

Q3: What are the storage and drying requirements for PEEK pellets?

A: It is recommended to dry at 120°C for 2 to 3 hours, keeping the moisture content below 0.02% to ensure the best molding effect.

Q4: Can it replace PEEK CF or GF reinforcing grades?

A: According to structural requirements, TK4600 can provide comparable or even better rigidity performance while maintaining light weight, making it particularly suitable for electrical insulation and wear-resistant applications.

08 | Similar Recommendations

For different application requirements, you can also choose:

| Производитель | Модель продукта | Плотность | Предел прочности | Удлинение | Усадка | Температура теплового прогиба | Твердость по Роквеллу | Izod Notched Impact Strength | Модуль упругости при изгибе | Izod Unnotched Impact Strength | Coefficient of Linear Thermal Expansion | Прочность на изгиб |

| Sumitomo Chemical | CK3420 | 1.42 g/cm³ | 163 MPa | 3.50% | 0.16% | 280 °C | 102 | 7.04 kJ/m² | 13500 MPa | 41.02 kJ/m² | 1.68E-5 cm/cm/°C | 206 MPa |

| Sumitomo Chemical | CK4600 | 1.44 g/cm³ | 216 MPa | 4.00% | 0.13% | 280 °C | 107 | 10 kJ/m² | 18200 MPa | 68.06 kJ/m² | 1.05E-3 cm/cm/°C | 333 MPa |

| Sumitomo Chemical | EK1420C | 1.36 g/cm³ | 134 MPa | 3.50% | 0.26% | 295 °C | — | — | 12800 MPa | 25.51 kJ/m² | — | 169 MPa |

09 | Our Advantages as an Export Supplier

As a professional PEEK pellets global supplier and material integration service provider, we not only provide raw materials, but also provide customers with:

・Technical selection guidance: Recommend the most suitable material system based on the application scenario;

・Processing optimization solution: Assist customers in improving the yield of injection molding and CNC processes;

・Customized formula service: Supports special modifications in aspects such as color, fluidity, and wear resistance;

・Global logistics and after-sales network: Quick response to ensure stable supply of materials.

We always believe that materials are not only part of manufacturing, but also part of competitiveness.

Choosing Sumitomo Chemical's PEEK TK4600 means choosing a higher-dimensional manufacturing capability and brand confidence.

Conclusion: Let materials define the future of manufacturing

In the process of global manufacturing moving towards high precision, lightweight and intelligence, PEEK pellets is becoming one of the core driving forces.

Sumitomo Chemical's PEEK TK4600, with its outstanding mechanical properties, flame retardant safety and sustainable design, is redefining the industry standards for high-performance plastics.

Whether you are in the aerospace, electrical equipment, automotive parts or precision manufacturing fields,

The TK4600 will all be a reliable high-end choice - from pellets to finished products, from technology to brand, fully empowering future manufacturing.

【Связанные рекомендации】

ColorRx® PEEK-3000RX: Medical-Grade peek raw material for Advanced Healthcare Узнать больше>

VESTAKEEP® 2000G | Flame-Retardant Medium-Viscosity PEEK Узнать больше>

PEEK 021GF30 — Reinforced PEEK Plastic Material Узнать больше>