ПРОДУКТЫ

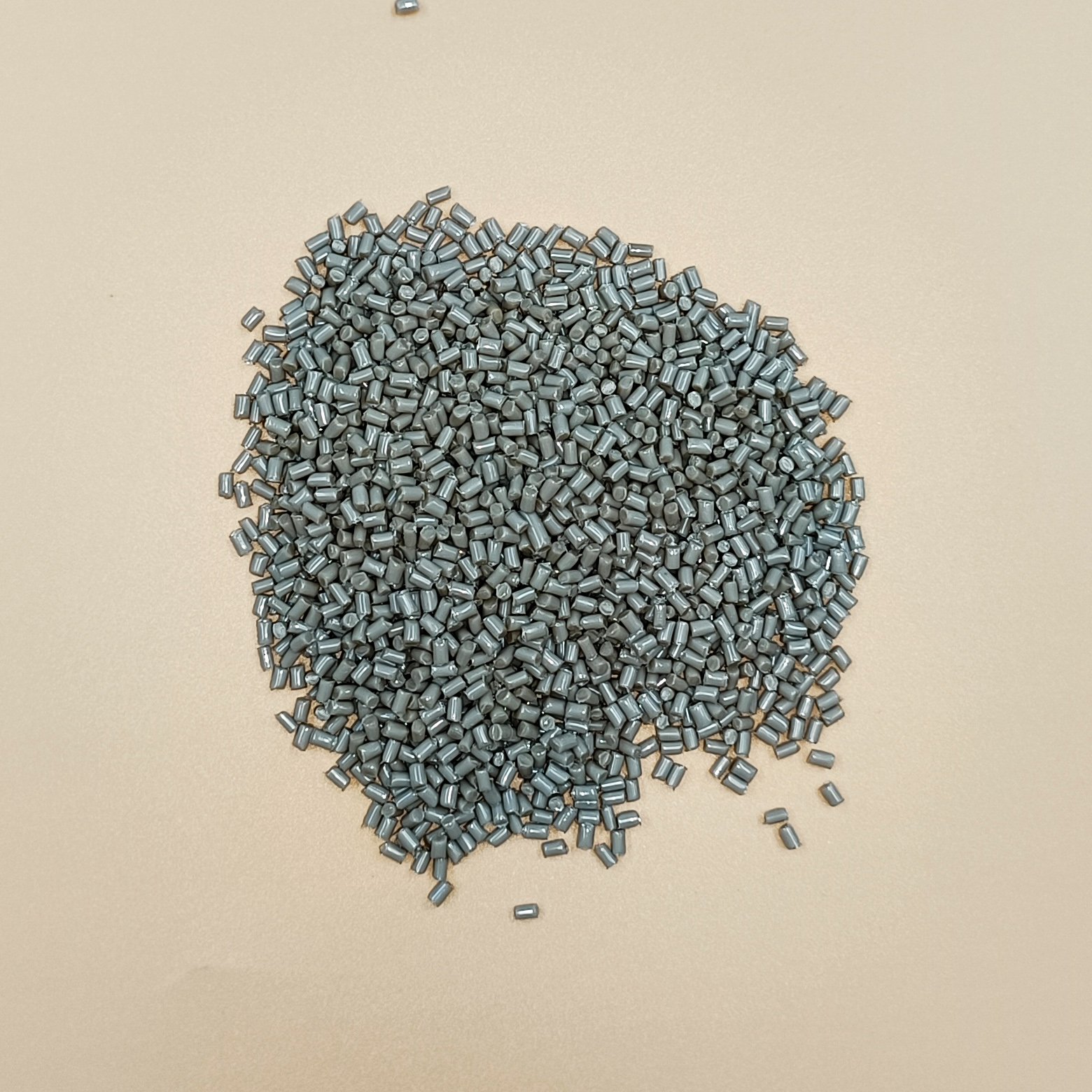

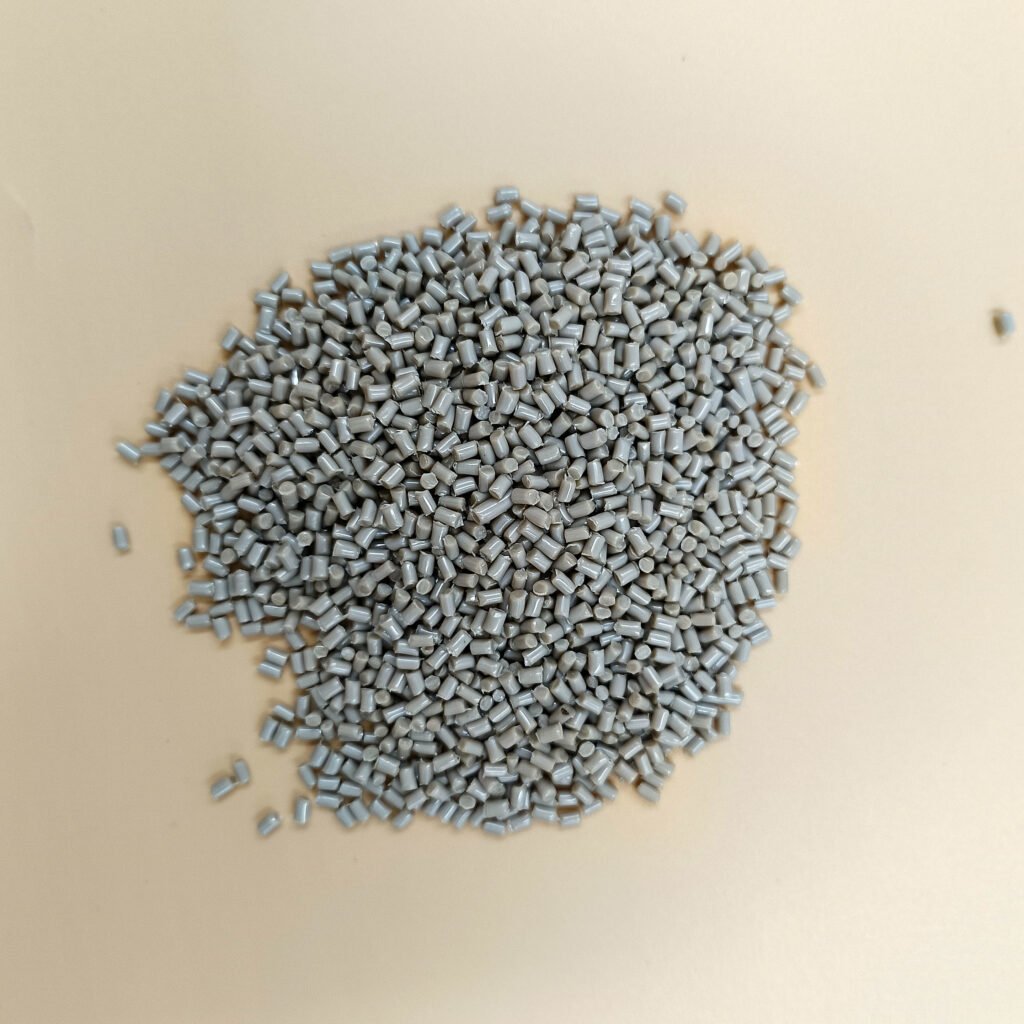

InLube™ Lubricated PEEK Polymer for Low-Friction Use

Структура продукта

What is PEEK Polymer

With the continuous increase in the demand for high-performance materials in the fields of automobiles, aerospace, medical and industrial equipment, PEEK polymer has become a core material in engineering plastics due to its excellent mechanical strength, heat resistance and wear resistance. The InLube™ series of lubricating PEEK polymer launched by Americhem, by adding PTFE lubricants and glass fiber/carbon fiber reinforcement, significantly enhance friction and wear resistance while ensuring strength and stability, providing a reliable solution for high-demand applications.

01 | The common characteristics of InLube™ PEEK Polymer

Lubrication performance: PTFE addition reduces the coefficient of friction and extends service life.

Reinforcement method: Glass fiber or carbon fiber reinforcement to enhance mechanical strength and dimensional stability.

Heat resistance performance: The maximum heat distortion temperature can reach up to 316℃.

Flame retardant performance: Some models comply with UL94 V-0.

Processability: All are suitable for injection molding processes.

These features make the InLube™ series an ideal choice for applications that require wear resistance, low friction and high temperature resistance.

02 | Application field

Automobile: gears, bearing housings, pump components

Aerospace: Friction parts, wear-resistant components

Medical: Structural components of medical devices (medical-grade models)

Промышленное оборудование: compressor parts, guiding components, sliding elements

03 | InLube™ Series Numerical Comparison Table

| Модель продукта | Плотность | Предел прочности | Удлинение | Shrinkage Rate | Модуль упругости | HDT | Твердость по Роквеллу | Notched Izod Impact Strength | Модуль упругости при изгибе | Unnotched Izod Impact Strength | CLTE | Прочность на изгиб |

| PEEKCF15TF15HF | 1.45 g/cm³ | 26000 psi | 1.0~2.0 % | 0.002~0.003 in/in | 2100000 psi | 600 ℉ | 124 | 1.1 ft-lb/in | 1900000 psi | 8.0 ft-lb/in | 1.8E-5 in/in/℉ | 38000 psi |

| PEEKGF20TF10 | 1.51 g/cm³ | 21000 psi | 2.5~4.0 % | 0.002~0.005 in/in | 1500000 psi | 550 ℉ | 1.8 ft-lb/in | 1400000 psi | 18 ft-lb/in | 30000 psi | ||

| PEEKCF20TF15 | 1.45 g/cm³ | 30000 psi | 1.0~3.0 % | 0.001~0.002 in/in | 600 ℉ | 124 | 1.2 ft-lb/in | 2550000 psi | 7.0 ft-lb/in | 1.4E-5 in/in/℉ | 43000 psi | |

| PEEKCF30TF15 | 1.50 g/cm³ | 33000 psi | 1.0~2.0 % | 0.001~0.0015 in/in | 600 ℉ | 124 | 1.5 ft-lb/in | 3700000 psi | 8.0 ft-lb/in | 8E-6 in/in/℉ | 50000 psi | |

| PEEKGF30TF15HFMD | 1.58 g/cm³ | 22000 psi | 1.0~2.0 % | 0.002~0.003 in/in | 600 ℉ | 124 | 1.6 ft-lb/in | 1000000 psi | 8.0 ft-lb/in | 1.2E-5 in/in/℉ | 21500 psi | |

| PEEKGF30TF10 | 1.60 g/cm³ | 23000 psi | 2.5~4.0 % | 0.002~0.005 in/in | 1700000 psi | 550 ℉ | 2.2 ft-lb/in | 1600000 psi | 18 ft-lb/in | 34000 psi | ||

| PEEKCF15TF15 | 1.47 g/cm³ | 20000 psi | 1.0~3.0 % | 0.002~0.003 in/in | 600 ℉ | 124 | 1.1 ft-lb/in | 1500000 psi | 5.0 ft-lb/in | 1.8E-5 in/in/℉ | 38000 psi | |

| PEEKGF30TF15 | 1.58 g/cm³ | 22000 psi | 1.0~2.0 % | 0.002~0.003 in/in | 600 ℉ | 124 | 1.6 ft-lb/in | 1000000 psi | 8.0 ft-lb/in | 1.2E-5 in/in/℉ | 21500 psi |

04 | Star rating comparison of InLube™ series features

| Модель продукта | Reinforcement System | Lubricity | Сила | Heat Resistance | Рейтинг пламени |

| PEEK-CF15-PTFE15-FR | 15% Carbon Fiber + 15% PTFE | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | В-0 |

| PEEK-GF20-PTFE10 | 20% Glass Fiber + 10% PTFE | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | - |

| PEEK-CF20-PTFE15-FR | 20% Carbon Fiber + 15% PTFE | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | В-0 |

| PEEK-CF30-PTFE15-FR | 30% Carbon Fiber + 15% PTFE | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | В-0 |

| PEEK-GF30-PTFE15 (Medical Grade) | 30% Glass Fiber + 15% PTFE | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | полупансион |

| PEEK-GF30-PTFE10 | 30% Glass Fiber + 10% PTFE | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | - |

| PEEK-CF15-PTFE15-FR | 15% Carbon Fiber + 15% PTFE | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | В-0 |

| PEEK-GF30-PTFE15 | 30% Glass Fiber + 15% PTFE | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | полупансион |

05 | Selection Guide

According to application requirements, InLube™ lubricated PEEK polymer can be classified into the following selection directions:

Pursue the highest strength and heat resistance

・Recommended models: PEEK-CF20-PTFE15-FR, PEEK-CF30-PTFE15-FR

・Application scenarios: High-load friction parts, aerospace structural components

Emphasize wear resistance and lubricity

・Recommended models: PEEK-CF15-PTFE15-FR, PEEK-GF30-PTFE15

・Application scenarios: Long-term sliding or contact applications of gears, bearings, pump components, etc

Medical industry demand (with equal emphasis on compliance and durability)

・Recommended model: PEEK-GF30-PTFE15 (Medical Grade)

・Application scenarios: Medical devices, precision components

Cost and performance balance

・Recommended models: PEEK-GF20-PTFE10, PEEK-GF30-PTFE10

・Application scenarios: Industrial equipment components, general friction parts

06 | Advantages over traditional materials

Compared with metals: lighter in weight, corrosion-resistant, and no need for additional lubrication.

Compared with PA and POM, its temperature resistance and strength have been significantly enhanced, making it suitable for more demanding environments.

Compared with unmodified PEEK: Optimized friction performance, more suitable for dynamic parts.

07 | Our advantages

As a professional PEEK Polymer supplier, we not only offer the full range of Americhem InLube™ series in stock, but also provide customers with:

Material selection consultation service: Recommend suitable models based on working conditions and requirements.

Fast delivery: Warehouse stocking to shorten the delivery time.

Technical support: Processing guidance and performance optimization suggestions.

International certification: Some models can be used for medical and aviation certification requirements.

08 | Summary

The Americhem InLube™ series of lubricating PEEK polymers, with their lubricity, wear resistance, high-temperature resistance and flame retardancy, demonstrate outstanding reliability in multiple industries. Whether it is high-strength automotive components, medical devices, or industrial friction parts, this series can provide ideal solutions. If you are looking for a PEEK Polymer with low friction, long service life and outstanding stability, the InLube™ series deserves priority consideration.

【Связанные рекомендации】

October 2025 Virgin Plastic Raw Materials Market Insights | Juyuan Perspective Узнать больше>

Victrex 450FE20 — PEEK Natural Material for Chemical & Wear Resistance Узнать больше>

Solvay Ketaspire™ KT 820 — Sterilizable PEEK Raw Material Узнать больше>