ПРОДУКТЫ

Solvay R-5100 NT15 PPSU Resin Steam-Sterilizable for Medical

Структура продукта

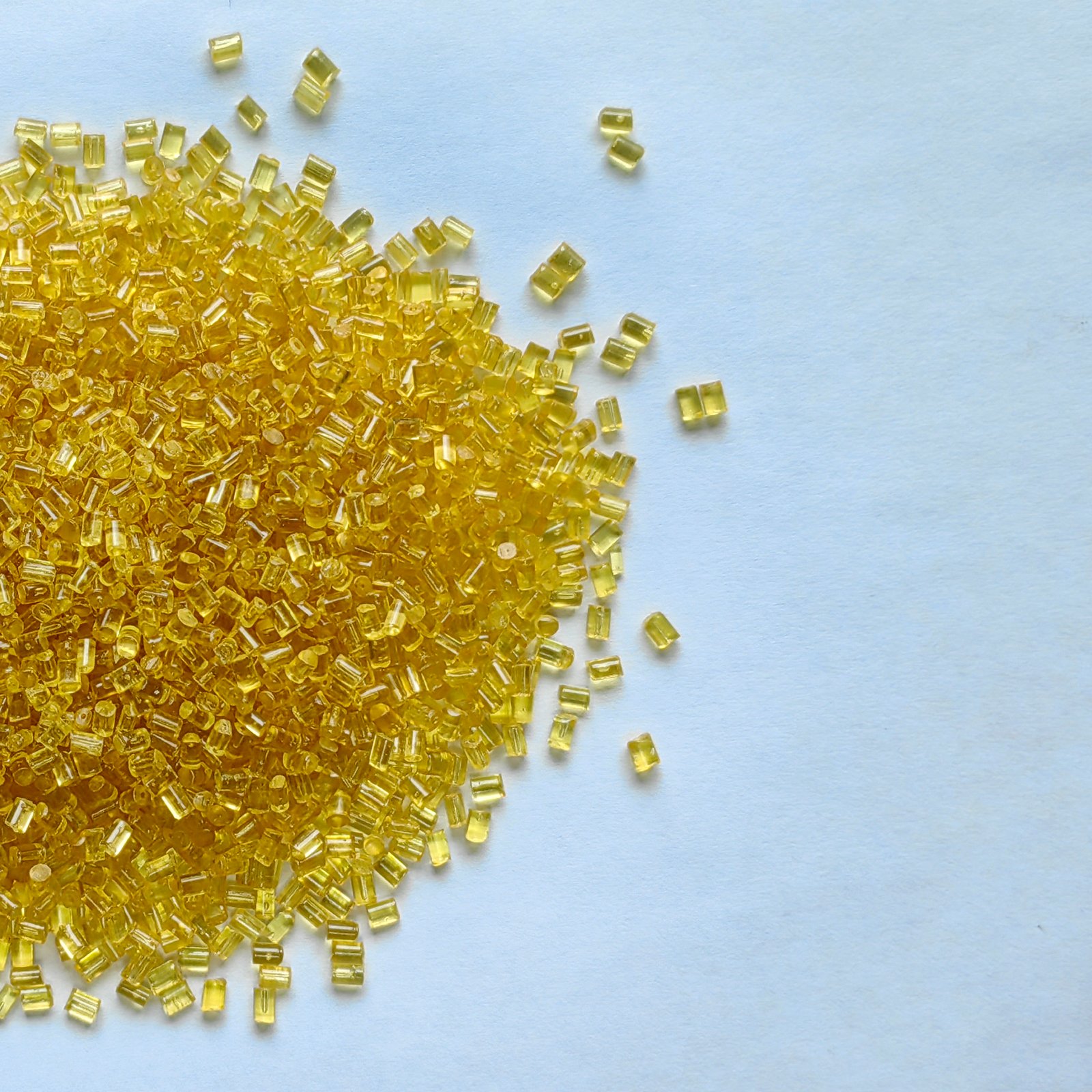

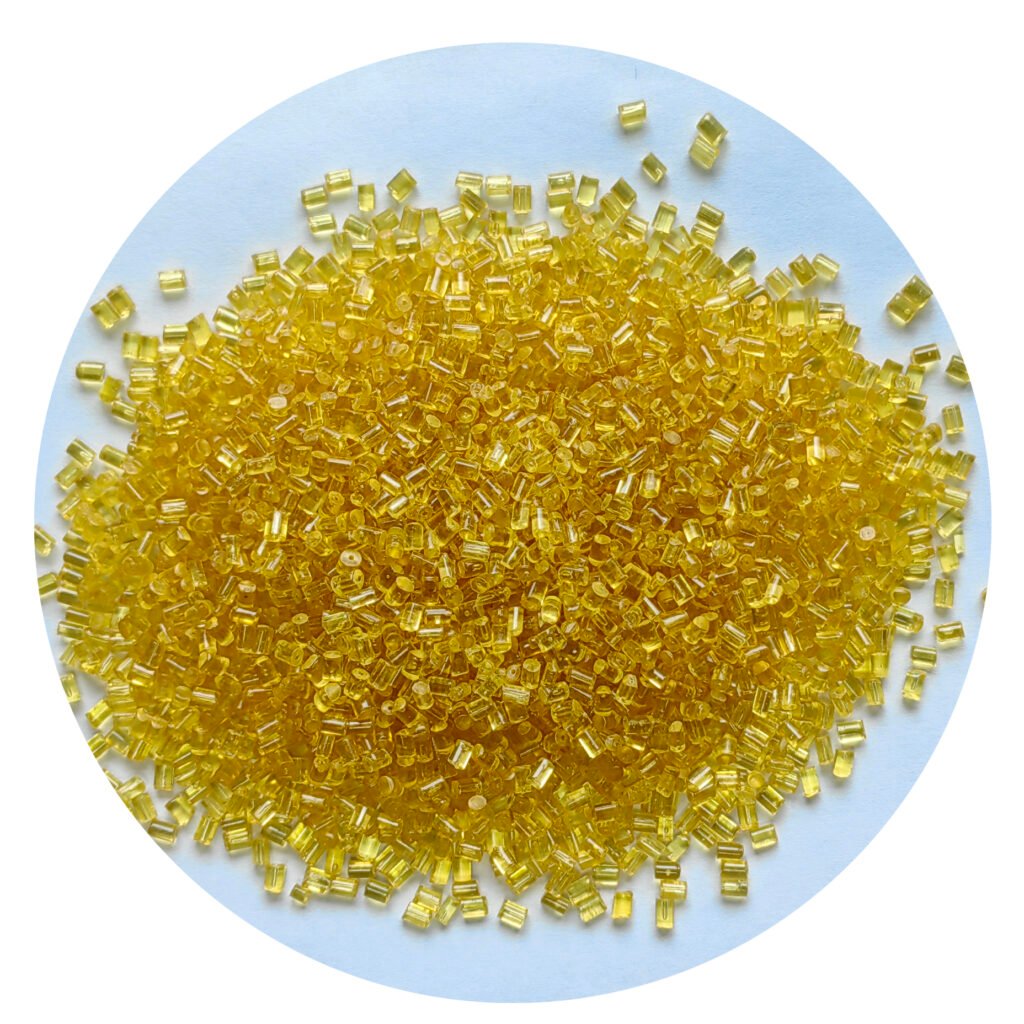

What is PPSU Resin

Facing application scenarios with increasingly high requirements for performance indicators such as heat, mechanics, and hygiene, engineering plastics are accelerating their development towards high performance. Polyphenylsulfone (PPSU resin) is becoming the main material in many fields such as medical, electrical and automotive due to its stable amorphous structure, high temperature resistance and excellent hydrolytic stability.

Among them, Solvay PPSU R-5100 NT15 is a film-grade PPSU resin for high-end applications. It not only possesses the balance of rigidity and toughness of engineering plastics, but also has passed the compliance certifications of multiple industries for flame retardancy, food contact and biosafety, making it suitable for various terminal products with high strength, high cleanliness and high temperature requirements.

01 | PPSU Resin Properties

Compared with ordinary engineering plastics, PPSU Resin R-5100 NT15 performs outstandingly in multiple key performance dimensions:

・It has excellent flame retardant performance, making it more reassuring to use in safety-sensitive environments

・It still maintains good dimensional stability in high-temperature environments and is suitable for long-term thermal load applications

・It has strong hydrolysis resistance and can undergo high-pressure steam sterilization multiple times without performance deterioration

・The amorphous structure brings higher impact resistance and is less prone to cracking

・It has good insulation performance and is stable and reliable in electronic and battery structures

・It can be safely used for contact with food and the human body, and meets multiple medical-grade and food-grade standards

02 | Summary of technical highlights: the balance between practicality and performance

To better adapt to different terminal manufacturing environments, the PPSU R-5100 NT15 offers distinct advantages in the following areas:

・High heat resistance: glass conversion temperature up to 220°C, ideal for thermal applications

・Rigid and soft: high tensile strength, elongation at break, can withstand repeated bending and clamping

・Suitable for disinfection process: even in high temperature water vapor repeated circulation, still can maintain structural stability

・Good electrical performance: suitable for connectors, battery pack structure, electrical shell and other parts that need insulation

03 | PPSU Resin Process and Processing Suggestions

R-5100 NT15, as a film-grade PPSU resin, is suitable for extrusion and injection molding processes. The following points are recommended to be noted in practical applications:

・Forming temperature control: It needs to be combined with a high-shear screw to ensure stable material flow

・The temperature control of the mold must be precise. Uneven cooling may lead to stress accumulation or warping

・Supports common secondary processing: laser welding, ultrasonic welding, surface coating and other treatments can be carried out

・The film has good transparency during processing and is suitable for structural components that require visual observation or light transmission

04 | Certification and Compliance

In addition to its material properties, the Solvay R-5100 NT15 has also passed several important industry certifications:

・Безопасность при контакте с пищевыми продуктами: Complies with FDA CFR 21 requirements

・Medical device grade: Passed ISO 10993 and USP Class VI tests

・The flame retardant performance reaches UL 94 V-0 level, and the oxygen index reaches 38%, which can be used for electronic and electrical components with clear flame retardant requirements

05 | Expansion of Application Directions

The Solvay R-5100 NT15 is not limited to a certain industry. Its comprehensive performance makes it suitable for a variety of complex working conditions:

・Medical equipment: sterilizable components, connection interfaces, transparent casings, etc

・Food-grade products: heating beverage utensils, water filter shells, baby bottle caps

・Automotive components: On-board electronic housing, thermal management components

・Electrical structural components: BMS battery module housing, high-temperature connectors

06 | PPSU Resin Solvay R-5100 NT15 Datasheet

| Механическое поведение | Состояние | Стандартный | Ценить | Единица | |||

| Удлинение | Выход потока | АСТМ Д882 | 9.2 | % | |||

| Удлинение | Cross-flow Yield | АСТМ Д882 | 6.8 | % | |||

| Удлинение | Разрыв потока | АСТМ Д882 | 140 | % | |||

| Удлинение | Cross-flow Break | АСТМ Д882 | 100 | % | |||

| Предел прочности | Выход потока | АСТМ Д882 | 68.0 | МПа | |||

| Предел прочности | Cross-flow Yield | АСТМ Д882 | 59.0 | МПа | |||

| Предел прочности | Разрыв потока | АСТМ Д882 | 92.0 | МПа | |||

| Предел прочности | Cross-flow Break | АСТМ Д882 | 70.0 | МПа | |||

| Прочность на разрыв | ASTM D1004 | 8.1 | cN | ||||

| Прочность на разрыв | ASTM D1922 | 140 | г | ||||

| Tensile Modulus (Secant) | Поток | АСТМ Д882 | 1590 | МПа | |||

| Tensile Modulus (Secant) | xFlow | АСТМ Д882 | 1980 | МПа | |||

| Dart Impact (Falling Weight Impact) | ASTM D1709 | 750 | г | ||||

| Термальный | Состояние | Стандартный | Ценить | Единица | |||

| HDT | Unannealed 1.80MPa 3.20mm | АСТМ Д648 | 207 | ℃ | |||

| Температура стеклования | АСТМ Е1356 | 220 | ℃ | ||||

| КЛЕ | Flow 3.20mm | АСТМ Д696 | 5.6E-5 | см/см/℃ | |||

| Физическая собственность | Состояние | Стандартный | Ценить | Единица | |||

| Поглощение воды | 24 часа | АСТМ Д570 | 0.37 | % | |||

| Плотность | АСТМ Д792 | 1.30 | г/см³ | ||||

| Электрические свойства | Состояние | Стандартный | Ценить | Единица | |||

| Диэлектрическая постоянная | АСТМ Д150 | 3.45 | |||||

| Объемное сопротивление | АСТМ Д257 | 9E15 | Ом.см | ||||

| Диэлектрическая прочность | 0.025mm | АСТМ Д149 | 190 | КВ/мм | |||

| Воспламеняемость | Состояние | Стандартный | Ценить | Единица | |||

| Предельный кислородный индекс | АСТМ Д2863 | 38 | % | ||||

07 | Frequently Asked Questions (FAQ)

Q1: Which medical sterilization methods are suitable?

It can withstand conventional sterilization methods such as high-temperature and high-pressure steam and ethylene oxide, and is not prone to aging even after repeated use.

Q2: Will the state of the film affect its mechanical properties?

No. Even in a film state, it still maintains excellent tensile strength and impact toughness.

Q3: Is personalized color customization supported?

The raw material is off-white. Color versions can be developed according to requirements, but the minimum order quantity condition must be met.

08 | Supply Advantage: Not only materials, but also services

Only when high-performance materials are combined with a professional supply and service system can they truly bring value to enterprises.

As a professional supplier of PPSU engineering plastics, we not only have the officially certified supply channels of Solvay, but also offer the following service advantages to our customers:

・Technical selection guidance: The most suitable material model can be recommended based on the product's application and processing conditions

・Small-batch sample support: Facilitates sampling, verification, and quick entry into project development

・Stable delivery time and sufficient inventory: ensuring that the mass production rhythm is not interrupted

・We can assist with certification and third-party testing, especially in food-grade and medical-grade applications

Whether you are a medical product manufacturer, an electrical structural component development enterprise, or a food service system integrator, we can provide you with reliable ppsu resin material solutions and flexible service support.

If you need free samples, технические параметры, comparison models or quotations, please feel free to contact us at any time. We are more than willing to assist you in quickly advancing the implementation of your project.

【Связанные рекомендации】

PESU 2010 MR:High Flow & Flame-Retardant PESU Polymer Узнать больше>

PPSU R-5000 NT High-Heat PPSU Resin for Medical and Food-Grade Injection Molding Узнать больше>

What is PPSU Material? A Panoramic Analysis and Market Opportunities of PPSU Engineering Plastics in 2025 Узнать больше>