ПРОДУКТЫ

Обзор пластиковых гранул HDPE LH523 | Свойства и технические характеристики

Структура продукта

HDPE LH523 — это высокопроизводительная полиэтиленовая (HDPE) пластиковая гранула натурального цвета, подходящая для литья под давлением и нанесения покрытий. Материал HDPE обладает превосходными свойствами, такими как высокий блеск, высокий удельный вес, высокая твердость, высокая ударная вязкость, высокая жесткость, низкая деформация, устойчивость к растрескиванию под напряжением и простота обработки, что делает его идеальным для требовательных продуктов, таких как картриджи с герметиком, корпуса вездеходов и покрытия.

ПРЕИМУЩЕСТВА ПРОДУКТА

Глянцевая поверхность для улучшения внешнего вида

HDPE LH523 имеет превосходную глянцевую поверхность, что делает поверхность конечного продукта гладкой и нежной, а также улучшает визуальный эффект и текстуру продукта.

Высокая жесткость и ударопрочность для повышенной долговечности

Сочетание высокой жесткости и высокой ударной вязкости позволяет изделиям сохранять отличную структурную устойчивость в суровых условиях, снижая риск повреждений.

Устойчивость к растрескиванию под напряжением для увеличения срока службы

Пластиковые гранулы HDPE обладают превосходными свойствами стойкости к растрескиванию под воздействием окружающей среды (ESCR), что позволяет им выдерживать длительные механические нагрузки и химическое воздействие, гарантируя, что изделия не будут легко растрескиваться при длительном использовании.

Низкая деформация и хорошая размерная стабильность

Оптимизированная молекулярная структура эффективно снижает коробление и деформацию при охлаждении и хранении, обеспечивая стабильную форму изделия для высокоточных применений.

Превосходные характеристики обработки, повышение эффективности производства

Легкость формования обеспечивает хорошую текучесть в процессе литья под давлением и нанесения покрытия, а также равномерное заполнение формы, что способствует повышению эффективности производства и снижению производственных затрат.

ПРИМЕНЕНИЕ ПРОДУКЦИИ

Картриджи с герметиком

Гранулы HDPE LH523 подходят для изготовления высокопрочных, долговечных картриджей с герметиком, устойчивых к растрескиванию и деформации в условиях высокого давления, что повышает безопасность строительства.

Корпус пляжного вездехода (ATV)

Высокая ударопрочность и устойчивость к атмосферным воздействиям делают его идеальным материалом для корпусов и компонентов квадроциклов, гарантируя высокую прочность и устойчивость в суровых условиях эксплуатации.

Применение покрытий

The пластик материал Гранулы подходят для создания высокоглянцевых, износостойких защитных покрытий, которые могут значительно улучшить долговечность и эстетичность поверхности изделий, а также повысить их коррозионную стойкость, что отвечает потребностям в обработке поверхностей в различных промышленных и потребительских секторах.

ПАРАМЕТРЫ ПРОДУКЦИИ

| Твердость | Состояние | Стандартный | Ценить | Единица | |||

| Берег | Твёрдость D | ASTM D2240 | 68 | ||||

| Механическое поведение | Состояние | Стандартный | Ценить | Единица | |||

| Удлинение | Перерыв | АСТМ Д638 | 300 | % | |||

| изгибный | Модуль | ASTM D747 | 8200 | кг/см² | |||

| Изод | Надрезное воздействие | АСТМ Д256 | 3.5 | кг-см/см | |||

| Секущая | Модуль 1% Формованный | АСТМ Д638 | 7600 | кг/см² | |||

| Растяжимый | Сила выхода | АСТМ Д638 | 230 | кг/см² | |||

| Торсион | Модуль | ASTM D1043 | 9200 | кг/см² | |||

| Физическая собственность | Состояние | Стандартный | Ценить | Единица | |||

| Плотность | АСТМ Д792 | 0.956 | г/см³ | ||||

| Таять | Индекс | АСТМ Д1238 | 23 | г/10мин | |||

| Термальный | Состояние | Стандартный | Ценить | Единица | |||

| Низкий | Температура хрупкости F50 | ASTM D746 | -76.0 | °С | |||

| плавление | Температура | ASTM D3418 | 132 | °С | |||

| Викат | Температура размягчения | АСТМ Д1525 | 125 | °С | |||

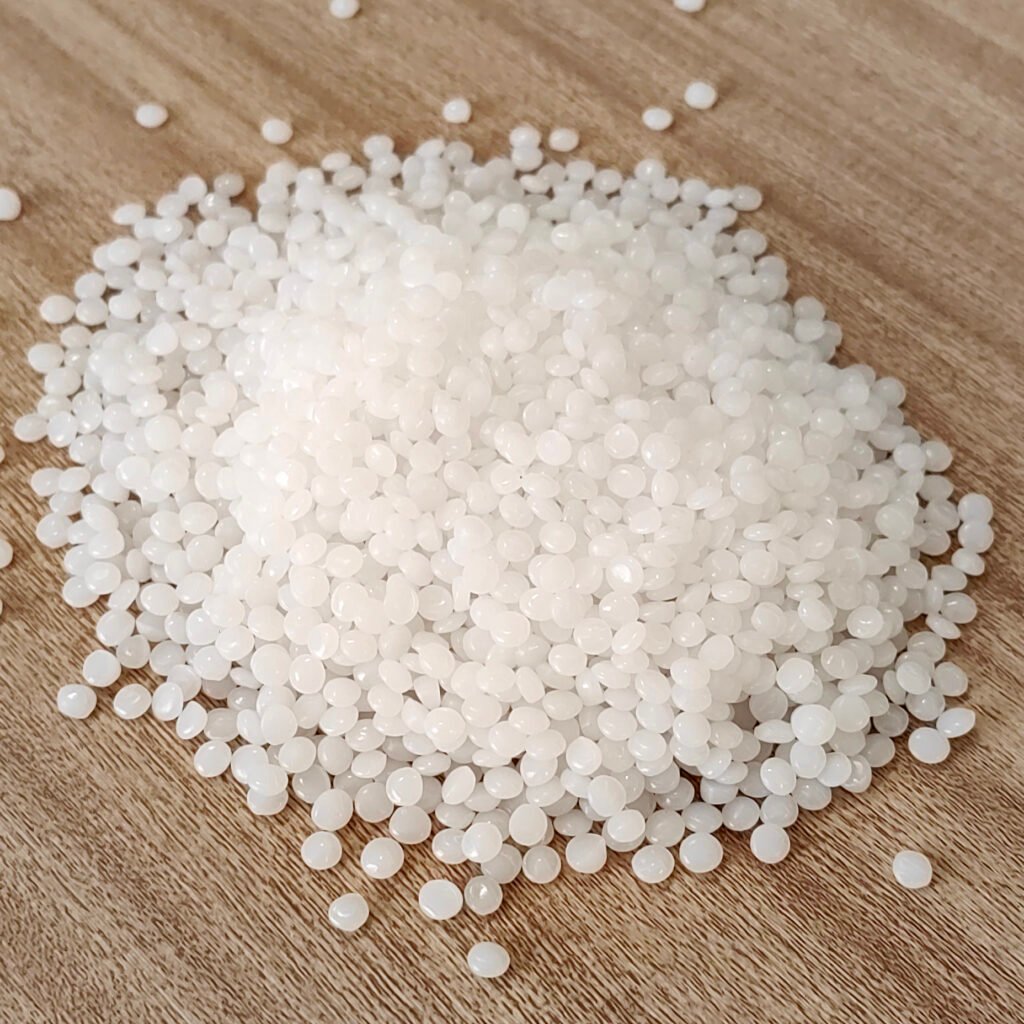

ДИСПЛЕЙ ПРОДУКТА

Нажмите здесь, чтобы загрузить TDS для ПЭВП LH523

СВЯЖИТЕСЬ С НАМИ

Свяжитесь с нами для получения более подробной информации о продукте! Если вы ищете высокопроизводительные пластиковые гранулы HDPE, свяжитесь с нами для получения более подробной информации о продукте и расценок. Давайте работать вместе, чтобы создавать высококачественные решения в области пластика!

【Связанные рекомендации】

ПЭВП DMDA8008: Высокопрочный литьевой HDPE гранула для прочных контейнеров Узнать больше>

HDPE Q TR-131: Высокопрочный пищевой полиэтилен высокой плотности гранула для прочной пленки Узнать больше>

ПЭВП 7000F: Высокопрочный выдувной ПЭВП материал для прочной пленки и упаковки Узнать больше>