PRODUCTEN

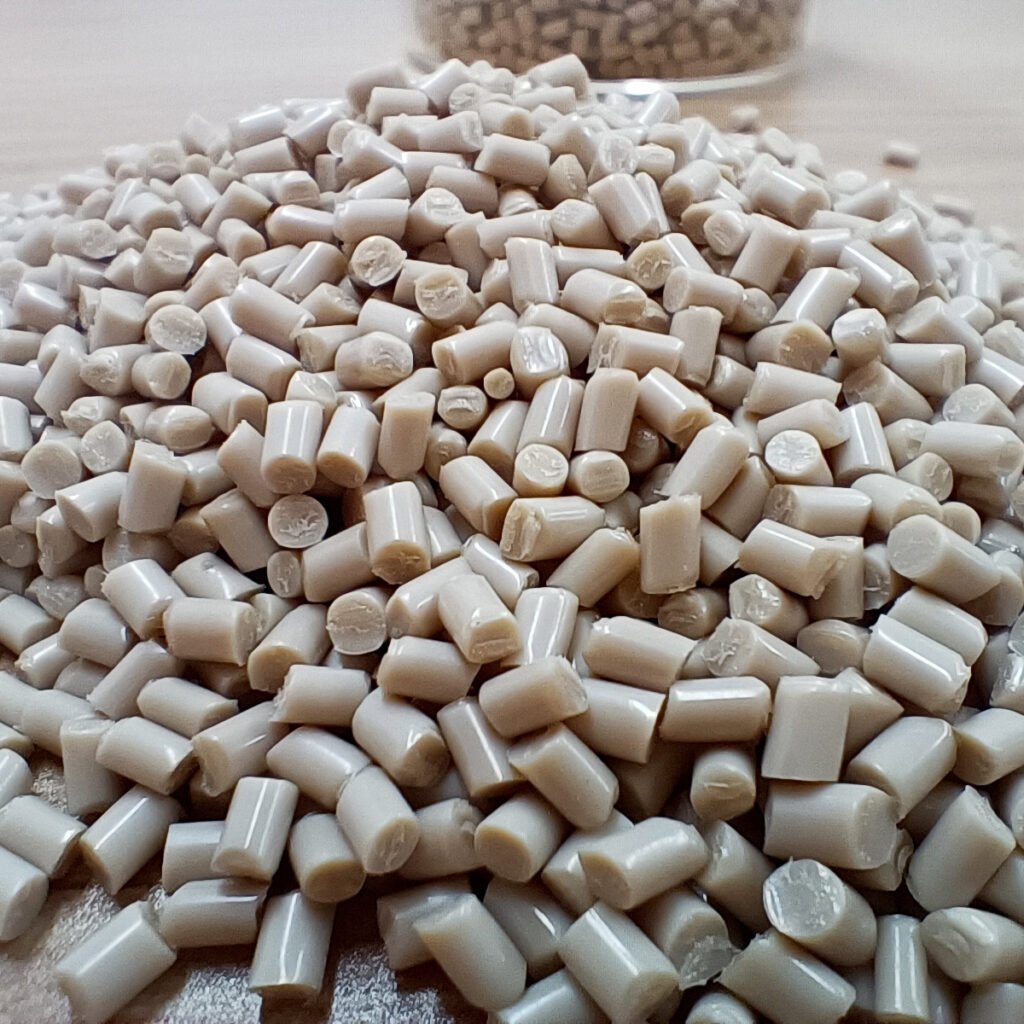

VESTAKEEP® PEEK 2000GF30: Natural PEEK for High-Rigidity

Productconstructie

What is Natural PEEK

Evonik VESTAKEEP® PEEK 2000GF30 is a glass fiber reinforced natural PEEK that stands out in the field of engineering plastics with its outstanding mechanical strength, thermal stability and electrical insulation performance. The material adopts a 30% glass fiber filling system, significantly enhancing rigidity and dimensional stability through structural reinforcement. It is suitable for structural components that require high load-bearing capacity and low deformation.

01 | Performance Analysis: High rigidity and stability coexist

High rigidity structural performance

The tensile modulus is approximately 11,000 MPa, and the tensile strength is about 165 MPa. Compared with unfilled natural PEEK, its rigidity is increased by more than twice, and it can significantly reduce deformation in mechanical components with high requirements for load-bearing and bending resistance.

Thermal stability and dimensional control

The heat distortion temperature reaches 338 °C (0.45MPa), and the Vicat softening point is 340 °C, ensuring that the structural form can still be maintained under high-temperature conditions.

Flame retardancy and electrical safety

It has passed the UL94 V-0 certification at a thickness of 1.6mm and passed the hot wire test at 960 °C, combining insulation strength and safety.

Excellent Dielectric Properties

The dielectric constant remains stable at 3.3–3.4 in the frequency range of 1 kHz to 1 MHz, making it suitable for high-frequency electronic and electrical equipment.

02 | Simplified Version Parameter Reference

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | Breuk 5 mm/min | ISO527 | 2 | % | |||

| Treksterkte | 5mm/min | ISO527 | 165 | MPa | |||

| Trekmodulus | ISO527 | 11000 | MPa | ||||

| Charpy Un-notch-impact | 23°C Complete destruction | ISO179 | 55 | kJ/m² | |||

| Charpy Un-notch-impact | -30°C Complete destruction | ISO179 | 65 | kJ/m² | |||

| Charpy Notch-impact | 23°C Complete destruction 1eA | ISO179 | 9 | kJ/m² | |||

| Charpy Notch-impact | -30°C Complete destruction 1eA | ISO179 | 8 | kJ/m² | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| HDT | 0,45 MPa | ISO75 | 338 | °C | |||

| HDT | 1,8 MPa | ISO75 | 323 | °C | |||

| Smelttemperatuur | DSC Secondary heating | INTERNE METHODE | 340 | °C | |||

| CLE | xFlow 23~55°C | ISO11359 | 3E-5 | cm/cm/°C | |||

| Vicat-verzachtingstemperatuur | 10N | ISO306 | 340 | °C | |||

| Vicat-verzachtingstemperatuur | 50N | ISO306 | 335 | °C | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Wateropname | 23°C | ISO62 | 0.4 | % | |||

| Krimp | Stroom | ISO294 | 0.4 | % | |||

| Krimp | xFlow | ISO294 | 0.9 | % | |||

| Dikte | 23°C | ISO1183 | 1.5 | g/cm³ | |||

| Smeltindex | 380°C 5kg | ISO1133 | 17 | cm³/10min | |||

| Elektrische eigenschappen | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CTI | EN 60112 | 200 | V | ||||

| Diëlektrische constante | 1KHz | EN 60250-norm | 3.3 | ||||

| Diëlektrische constante | 1 MHz | EN 60250-norm | 3.3 | ||||

| Diëlektrische constante | 50Hz | EN 60250-norm | 3.4 | ||||

| Volumeweerstand | IEC 60093 | 1E15 | Ω.cm | ||||

| Diëlektrische sterkte | K20/K20 | IEC 60243 | 23 | kv/mm | |||

| Diëlektrische sterkte | K20/P50 | IEC 60243 | 25 | kv/mm | |||

| Dissipatiefactor | 1KHz | EN 60250-norm | 0.002 | ||||

| Dissipatiefactor | 1 MHz | EN 60250-norm | 0.004 | ||||

| Oppervlakteweerstand | IEC 60093 | 1E14 | Ω | ||||

| Ontvlambaarheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Beperkende zuurstofindex | 3.20mm | ISO 4589 | 45 | % | |||

| GWFI | IEC 60695 | 960 | °C | ||||

| GWFI | 2 mm | IEC 60695 | 875 | °C | |||

| Vlamclassificatie | 0,8 mm | UL94 | V-1 | ||||

| Vlamclassificatie | 1,6 mm | UL94 | V-0 | ||||

03 | Application Fields

With its high rigidity and thermal stability, VESTAKEEP® PEEK 2000GF30 is widely used in:

・Electronic and electrical equipment: connectors, insulating brackets, motor housings

・Mechanical structural components: bearing housing, support ring, compression ring, valve body

・Aerospace: Lightweight structural support and composite cladding components

・Industrial automation: High-precision sliding and motion components

In these scenarios, the high rigidity and dimensional stability of natural PEEK significantly reduce stress deformation and assembly deviation, and extend the service life of parts.

04 | Processing and Technology Suggestions

This material is medium-viscosity injection-grade PEEK, suitable for complex geometric parts and multi-chamber molds.

・Barrel temperature: 360-400 °C

・Mold temperature: 170-200 °C

・Drying conditions: 150 °C for 3 hours

The 30% glass fiber system results in a low shrinkage rate after molding (about 0.4% - 0.9%), making it suitable for precision mating parts.

05 | Suggestions for Engineer Selection

For engineers and purchasers, the following three points can be given priority consideration when making selections:

・High-rigidity alternatives to metal parts: In light-load or medium-load structures, natural PEEK 2000GF30 can be used to replace aluminum alloys, achieving the dual benefits of weight reduction and insulation.

・Heat resistance and long-term stability: In high-temperature electrical assembly, the 338 °C heat distortion temperature can ensure the long-term dimensional accuracy of parts.

・Integrated design of injection molding structure: Compared with metal machined parts, the injection molding PEEK structure can reduce assembly complexity and manufacturing costs.

✅ Selection conclusion: When the application needs to balance the three elements of "high rigidity, flame retardancy and thermal stability", VESTAKEEP® PEEK 2000GF30 is an ideal natural PEEK solution.

06 | Industry Trends

With the development of lightweighting in electronics and electrical engineering and high power density, PEEK materials with high rigidity and insulation are replacing some traditional engineering plastics.

The natural PEEK series has seen a continuous increase in demand in the aviation, semiconductor and new energy industries due to its pure system and good processability.

07 | Similar Recommendations

| Fabrikant | Productmodel | Description | Soortelijk gewicht | Melt Flow Index | Treksterkte | Verlenging | Krimp | Smelttemperatuur | Trekmodulus | Warmteafbuigingstemperatuur | Vicat-verzachtingstemperatuur | Coefficient of Linear Expansion | Viscositeit |

| Polyplastics - Evonik | 2000CF30 | Material Features: High rigidity Applications: Electronic and electrical components • Mechanical parts • Composite molding • Aerospace | 1.38 g/cm³ | 10 cm³/10min | 240 MPa | 2% | 0.10% | 340°C | 23,000 MPa | 340°C | 343°C | 1E-5 cm/cm/°C | Gemiddelde viscositeit |

| Polyplastics - Evonik | 4000CF30 | Material Features: High rigidity Applications: Composite molding | 1.4 g/cm³ | 3 cm³/10min | 240 MPa | 2% | 0.10% | 340°C | 23,000 MPa | 335°C | 343°C | 1E-5 cm/cm/°C | High viscosity |

| Polyplastics - Evonik | 4000GF30 | Material Features: High rigidity Applications: Composite molding | 1.5 g/cm³ | 2 cm³/10min | 165 MPa | 2% | 0.40% | 340°C | 11,000 MPa | 335°C | 340°C | 3E-5 cm/cm/°C | High viscosity |

08 | FAQ

Q1: In what aspects does the high rigidity of VESTAKEEP® PEEK 2000GF30 manifest?

A1: With a tensile modulus as high as approximately 11,000 MPa, it can maintain structural stability under high temperatures and loads, making it a typical high-rigidity natural PEEK.

Q2: Can this material replace metal parts?

A2: It can partially replace aluminium or stainless steel in many electrical and mechanical structures, reducing weight by approximately 60%, and it also has insulating and corrosion-resistant properties.

Q3: Is any special equipment required for processing?

A3: A regular injection molding machine is sufficient. It is recommended to use equipment with a high-temperature barrel and a temperature-controlled mold to ensure uniform crystallization and surface quality.

09 | Juyuan's Advantages in Foreign Trade Supply

Juyuan focuses on the international trade of engineering plastics and provides customers with natural PEEK through original factory channels.

We support multi-brand technology comparison, formula consultation and process optimization to help global customers achieve the best balance between performance and cost.

【Gerelateerde aanbevelingen】

VESTAKEEP® 2000FC30: Composite Lubrication Natural PEEK Material Meer informatie>

PEEK-OPTIMA® LT1 Medical-Grade Polyether Ether Ketone PEEK Meer informatie>

Cosmetic Packaging Plastic Material Selection & Procurement Guide Meer informatie>