PRODUCTEN

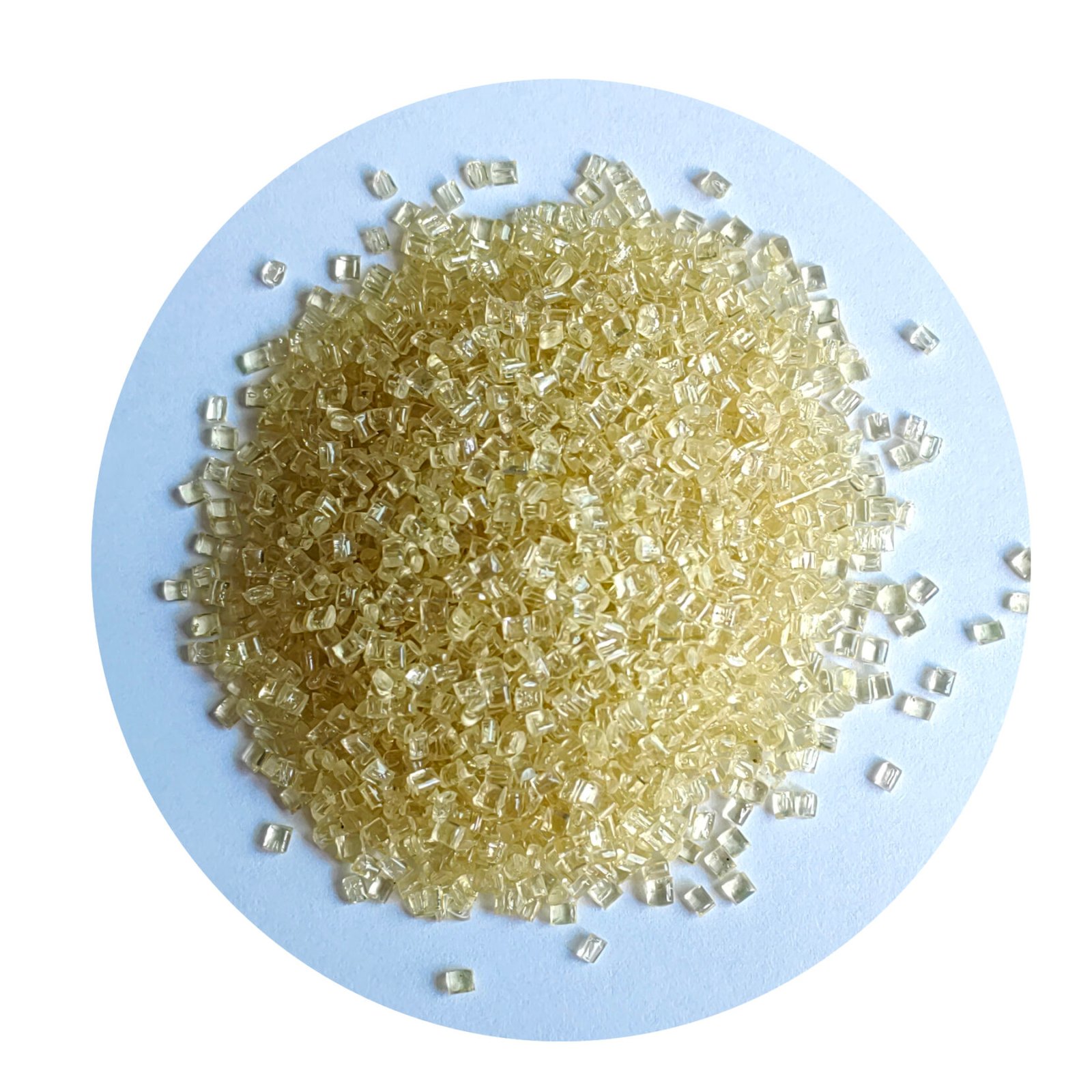

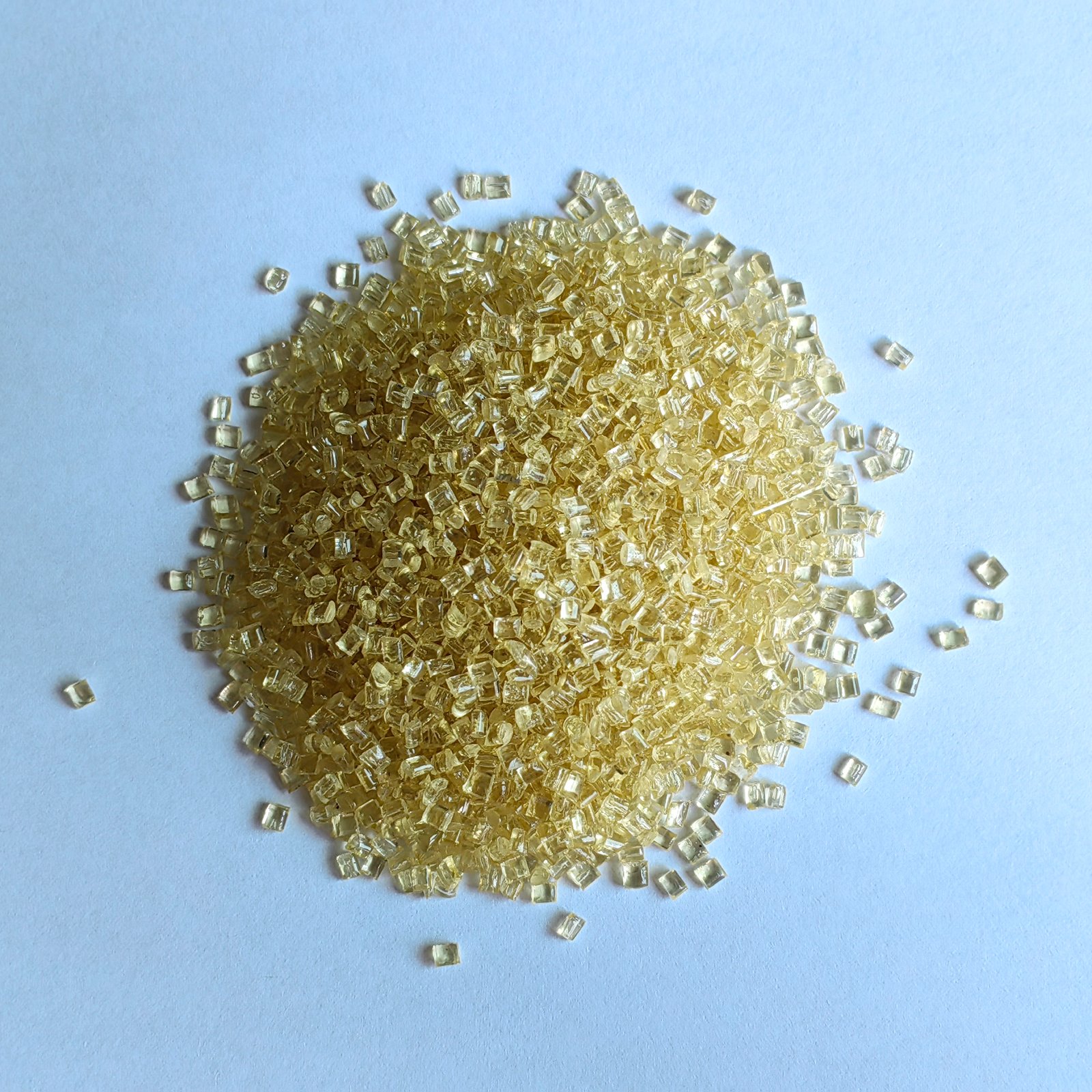

Ultrason P 3010 BASF PPSU | Baby Bottles & Medical Grade

Productconstructie

What is Ultrason P 3010

In the field of engineering plastics, polyphenylsulfone (PPSU) is widely used in medical, food contact and industrial fields due to its properties such as flame retardancy, high-temperature resistance, chemical corrosion resistance and stable mechanical strength. Ultrason P 3010 is a PPSU injection molding grade material launched by BASF. With its high-viscosity formula and outstanding comprehensive performance, it has become an ideal raw material for the manufacturing of infant products, medical devices and high-end consumer goods.

01 | Material highlights and characteristics

High-viscosity design: Suitable for complex injection molded products, with both fluidity and toughness.

Outstanding flame retardancy: Complies with UL94 V-0 grade, ensuring the product can be used in high-safety standard environments.

Chemische bestendigheid: Suitable for harsh usage scenarios such as disinfectants and cleaning agents, and not prone to aging.

Strong thermal stability: The heat distortion temperature is close to 200°C, and it can withstand repeated high-temperature sterilization.

Excellent impact strength: It maintains good toughness at low temperatures, reducing the risk of brittle cracking.

Veiligheid van voedselcontact: Complies with relevant regulations and is applicable to infant bottles, tableware, etc.

02 | Typical application fields

Infant and toddler care: baby bottles, drinking cups, anti-overflow caps, etc., taking into account both safety and durability.

Medical devices: Surgical instrument handles, disinfection containers, meeting the requirements of high-temperature and high-pressure sterilization.

Consumer electronics: Transparent components for high-end home appliances, which are both aesthetically pleasing and durable.

Industrial components: Parts that require chemical resistance and electrical insulation.

03 | Ultrason P 3010 Data Sheet

| Elektrische eigenschappen | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CTI | EN 60112 | 150 | V | ||||

| Diëlektrisch | Kracht | IEC 60243 | 44 | kv/mm | |||

| Diëlektrisch | Constante 100Hz | EN 60250-norm | 3.80 | ||||

| Diëlektrisch | Constante 1MHz | EN 60250-norm | 3.70 | ||||

| Verkwisting | Factor100Hz | EN 60250-norm | 0.0017 | ||||

| Verkwisting | Factor1 MHz | EN 60250-norm | 0.0089 | ||||

| Oppervlak | Weerstand | IEC 60093 | 1E+15 | Ω | |||

| Volume | Weerstand | IEC 60093 | 1E+15 | Ω.cm | |||

| Ontvlambaarheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Vlam | Waardering Alle kleuren 1,5 mm | UL94 | V-0 | ||||

| Vlam | Waardering Alle kleuren 3,0 mm | UL94 | V-0 | ||||

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Bal | Indentation Hardness | ISO2039 | 124 | MPa | |||

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Charpy | Kerfimpact -30°C | ISO179 | 25 | kJ/m² | |||

| Charpy | Kerfslag 23°C | ISO179 | 75 | kJ/m² | |||

| Charpy | Impact zonder kerf -30°C | ISO179 | Let op | kJ/m² | |||

| Charpy | Uitkerving Impact 23°C | ISO179 | Let op | kJ/m² | |||

| Verlenging | Opbrengst 23°C | ISO527 | 7.8 | % | |||

| Izod | Kerf Impact -30°C | ISO180 | 25 | kJ/m² | |||

| Izod | Kerfslag 23°C | ISO180 | 55 | kJ/m² | |||

| Treksterkte | Modulus 23°C | ISO527 | 2270 | MPa | |||

| Treksterkte | Sterkte Opbrengst 23°C | ISO527 | 74.0 | MPa | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | ISO1183 | 1.29 | g/cm³ | ||||

| Smelten | Index 360°C 10kg | ISO1133 | 35 | cm³/10min | |||

| Krimp | xFlow | ISO294 | 1.0 | % | |||

| Krimp | Stroom | ISO294 | 0.90 | % | |||

| Water | Absorptie 23°C Verzadiging | ISO62 | 1.2 | % | |||

| Water | Absorption 23°C 50RH Equilibrium | ISO62 | 0.60 | % | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CLE | Stroom | 5.5E-5 | cm/cm/°C | ||||

| HDT | Niet-gegloeid 1,8 MPa | ISO75 | 198 | °C | |||

| UL | Voorwaarde | Standaard | Waarde | Eenheid | |||

| UL | Vlamwaarde ALLES 1,5 mm | UL94 | V-0 | ||||

| UL | Vlamclassificatie ALLES 3,0 mm | UL94 | V-0 | ||||

04 | Technology and processing techniques

Ultrason P 3010 is mainly injection molded and has a wide processing window, making it suitable for large-scale stable production.

・The ppsu material has a low shrinkage rate and high dimensional accuracy during the injection molding process.

・The high viscosity property enhances the filling effect of complex molds.

・Compatible with multiple surface treatment processes, it is suitable for transparent or colored designs.

・Thin-walled parts can be formed through mold optimization, reducing weight and material consumption.

05 | Innovation and industry competitive advantage

Compared with traditional PC or PSU materials, Ultrason P 3010 shows significant differentiation in terms of chemical resistance, thermal stability and flame retardancy:

・It offers higher long-term safety in food contact and medical-grade applications.

・In high-temperature environments, it maintains stable mechanical properties and reduces cracking and deformation of the products.

・In the context of increasingly strict regulations, it has become a reliable solution for enterprises to pursue compliance and innovation.

06 | Customer feedback

Feedback from medical and infant product manufacturers indicates:

・The baby bottles produced with Ultrason P 3010 maintain good transparency and toughness after repeated high-temperature disinfection.

・Medical customers have pointed out that it is significantly superior to conventional materials in terms of resistance to chemical corrosion, thus extending the service life of the products.

・Consumer goods customers generally recognize the advantages of this material in design flexibility and processing stability.

07 | FAQ

Q1: Is Ultrason P 3010 suitable for long-term food contact?

A1: Yes, the material meets relevant food contact safety standards and is suitable for products such as baby bottles and tableware.

Q2: Will it deform in high-temperature environments?

A2: This material has a heat deflection temperature approaching 200°C and can withstand repeated steam sterilization and high-temperature applications.

Q3: Can it replace PC?

A3: Ultrason P 3010 offers advantages over PC in terms of chemical resistance and flame retardancy, making it suitable for applications requiring higher safety and longevity.

08 | Similar recommendations

| Fabrikant | Product Name | Productmodel | Value Summary | Description | Dikte | Melt Flow Index | Unit Price (Negotiable) |

| BASF | PPSU | 3010 MR WS 20264 | Viscosity: High ViscosityFlame Retardant Grade: V-0Notched Impact: 55 kJ/m² | Material Properties: Unreinforced | 1.29 g/cm³ | 80 cm³/10min | 200 RMB |

| BASF | PPSU | 3010 MR SW 10101 | Viscosity: High ViscosityFlame Retardant Grade: V-0Notched Impact: 60 kJ/m² | Material Properties: Unreinforced | 1.31 g/cm³ | 35 cm³/10min | 190 RMB |

| BASF | PPSU | 3010 MR GR 30373 | Viscosity: High ViscosityFlame Retardant Grade: V-0Notched Impact: 55 kJ/m² | Material Properties: Unreinforced | 1.29 g/cm³ | 35 cm³/10min | 190 RMB |

09 | The advantages of Juyuan as an international supplier

As a company specializing in international trade of plastic raw materials, Juyuan is committed to providing customers with:

・Multi-channel stable supply: Long-term cooperation with many international first-line manufacturers ensures an adequate supply of goods.

・Professional material selection support: Based on the product requirements of customers, we recommend the best solutions.

・Global logistics network: Fast delivery, reducing supply chain uncertainty.

・Long-term partnership: Not only providing materials, but also focusing on enhancing the market competitiveness of customers

【Gerelateerde aanbevelingen】

Mitsubishi Sultron™ PPSU LSG: High-Heat, Flame-Retardant Medical R5500/XL Meer informatie>

HiFill® PPSU Series: Tailored Plastics for Demanding Applications Meer informatie>

LNP™ THERMOCOMP™ 9X10401H Filled PPSU for Medical Meer informatie>