PRODUCTEN

Polyfenylsulfon 9X04488 (PDX-04488) Overzicht en gegevensblad

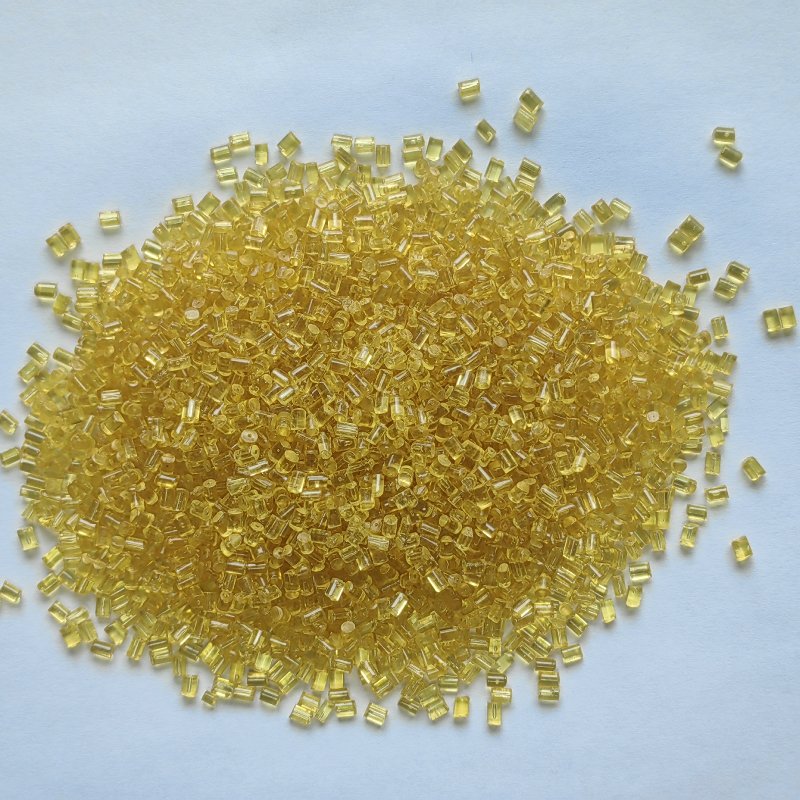

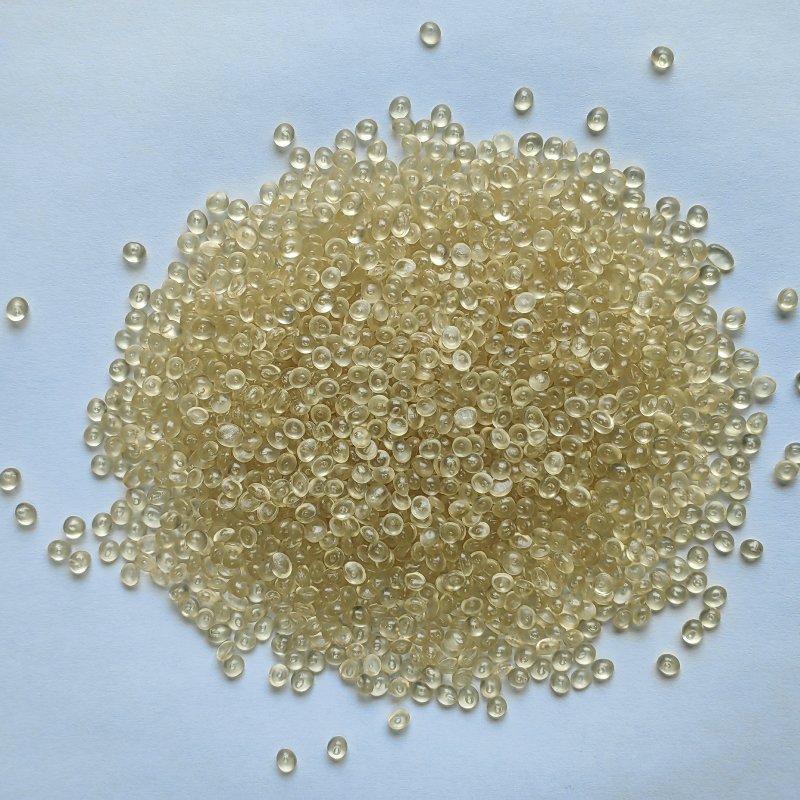

Productconstructie

Polyfenylsulfon 9X04488 (PDX-04488) Overzicht

PPSU-9X04488 (PDX-04488) is een mineraalgevuld, vlamvertragend polyfenylsulfon (PPSU) materiaal dat is ontworpen voor spuitgieten. Het heeft een V-0-classificatie voor vlamvertraging en, als ik me niet vergis, wordt gedacht dat het uitstekende fysieke eigenschappen behoudt bij hoge temperaturen, hoge vochtigheid en in zware omstandigheden.

1、Poliephenylsulfon 9X04488 (PDX-04488) Ptouwtjes

Uitstekende vlamvertraging (V-0-classificatie) om te voldoen aan strenge veiligheidsnormen

Mineraalgevulde formules voor verbeterde hittebestendigheid en maatvastheid

Hoge temperatuur- en chemische bestendigheid voor gebruik in zware omstandigheden

Hoge mechanische sterkte en goede taaiheid voor duurzaamheid en slagvastheid

Goede vloeibaarheid voor precisie-spuitgieten

2、Polyfenylsulfon 9X04488 (PDX-04488) Toepassing

Polyfenylsulfon 9X04488 (PDX-04488) is geschikt voor toepassingen waarbij een hoge hittebestendigheid en vlamvertragende eigenschappen vereist zijn, waaronder:

Elektronica en elektronica: hoogwaardige behuizingen voor apparaten, connectoren, schakelonderdelen

Automobielproductie: auto-onderdelen die bestand zijn tegen hoge temperaturen, elektrische componenten

Industriële apparatuur: pompen en kleppen, vloeistofbehandelingssystemen.

Medische hulpmiddelen: gesteriliseerde medische hulpmiddelcomponenten die bestand zijn tegen hoge temperaturen

3、Polyfenylsulfon 9X04488 (PDX-04488) Verwerking

Polyfenylsulfon 9X04488 (PDX-04488) zou een spuitgietproces met een uitstekende vloeibaarheid gebruiken, wat geschikt zou kunnen zijn voor de productie van complexe onderdelen met een hoge precisie en duurzaamheid, en zou kunnen voldoen aan de strenge eisen van industriële productie.

4、Polyfenylsulfon 9X04488 (PDX-04488) Gegevensblad

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | Opbrengst | ASTM D638 | 8.2 | % | |||

| Verlenging | Pauze | ASTM D638 | 19.2 | % | |||

| Verlenging | Opbrengst | ISO527 | 7.7 | % | |||

| Verlenging | Pauze | ISO527 | Let op | % | |||

| Buigzaam | Kracht | ASTM D790 | 96 | MPa | |||

| Buigzaam | Kracht | ISO178 | 71 | MPa | |||

| Buigzaam | Module | ASTM D790 | 2460 | MPa | |||

| Buigzaam | Module | ISO178 | 2090 | MPa | |||

| Geïnstrumenteerd | Impact 23°C Piekenergie | ASTM D3763 | 51 | J | |||

| Izod | Kerfslag 23°C | ASTM D256 | 363 | J/m | |||

| Izod | Kerf Impact 23°C 4,0mm Type A | ISO180 | 14 | kJ/m² | |||

| Izod | Uitkerving Impact 23°C | ASTM D4812 | 2563 | J/m | |||

| Izod | Un-notch Impact 23°C 4,0 mm | ISO180 | Let op | kJ/m² | |||

| Multiaxiaal | Invloed | ISO 6603 | 59 | J | |||

| Treksterkte | Modulus 50 mm/min | ASTM D638 | 2280 | MPa | |||

| Treksterkte | Modulus 1,0 mm/min | ISO527 | 2120 | MPa | |||

| Treksterkte | Sterkte opbrengst | ASTM D638 | 74 | MPa | |||

| Treksterkte | Sterkte pauze | ASTM D638 | 59 | MPa | |||

| Treksterkte | Sterkte opbrengst | ISO527 | 69 | MPa | |||

| Treksterkte | Sterkte pauze | ISO527 | Let op | MPa | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | ASTM D792 | 1.31 | g/cm³ | ||||

| Dikte | ISO1183 | 1.31 | g/cm³ | ||||

| Krimp | Stroom 24 uur | ASTM D955 | 0.9~1.1 | % | |||

| Krimp | xFlow 24 uur | ASTM D955 | 1~1.2 | % | |||

| Krimp | Stroom 24 uur | ISO294 | 0.9~1.1 | % | |||

| Krimp | xFlow 24 uur | ISO294 | 1~1.2 | % | |||

| Water | Absorptie 50RH 24 uur | ASTM D570 | 0.3 | % | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CLE | Stroom -40,0~40°C | ASTM E831 | 5.4E-5 | cm/cm/°C | |||

| CLE | xFlow -40.0~40°C | ASTM E831 | 5.22E-5 | cm/cm/°C | |||

| CLE | Stroom -40,0~40°C | ISO11359 | 5.33E-5 | cm/cm/°C | |||

| CLE | xFlow -40.0~40°C | ISO11359 | 5.24E-5 | cm/cm/°C | |||

| HDT | Niet-gegloeid 1,8 MPa 3,2 mm | ASTM D648 | 200 | °C | |||

| HDT | 1,8 MPa 4,0 mm | ISO75 | 195 | °C | |||

Als u meer informatie of een offerte voor PPSU 9X04488 (PDX-04488) wilt, neem dan gerust contact met ons op.

【Gerelateerde aanbevelingen】

Voeding P-1710: Chemisch bestendige thermoplast voor elektronica, industriële toepassingen Meer informatie>

PPSU R-5000 CL 301: Hittebestendige PPSU-hars voor automobieltoepassingen Meer informatie>

PPSU-22000: Hittebestendig en hydrolysebestendig polymeer voor sanitaire apparatuur Meer informatie>