PRODUCTEN

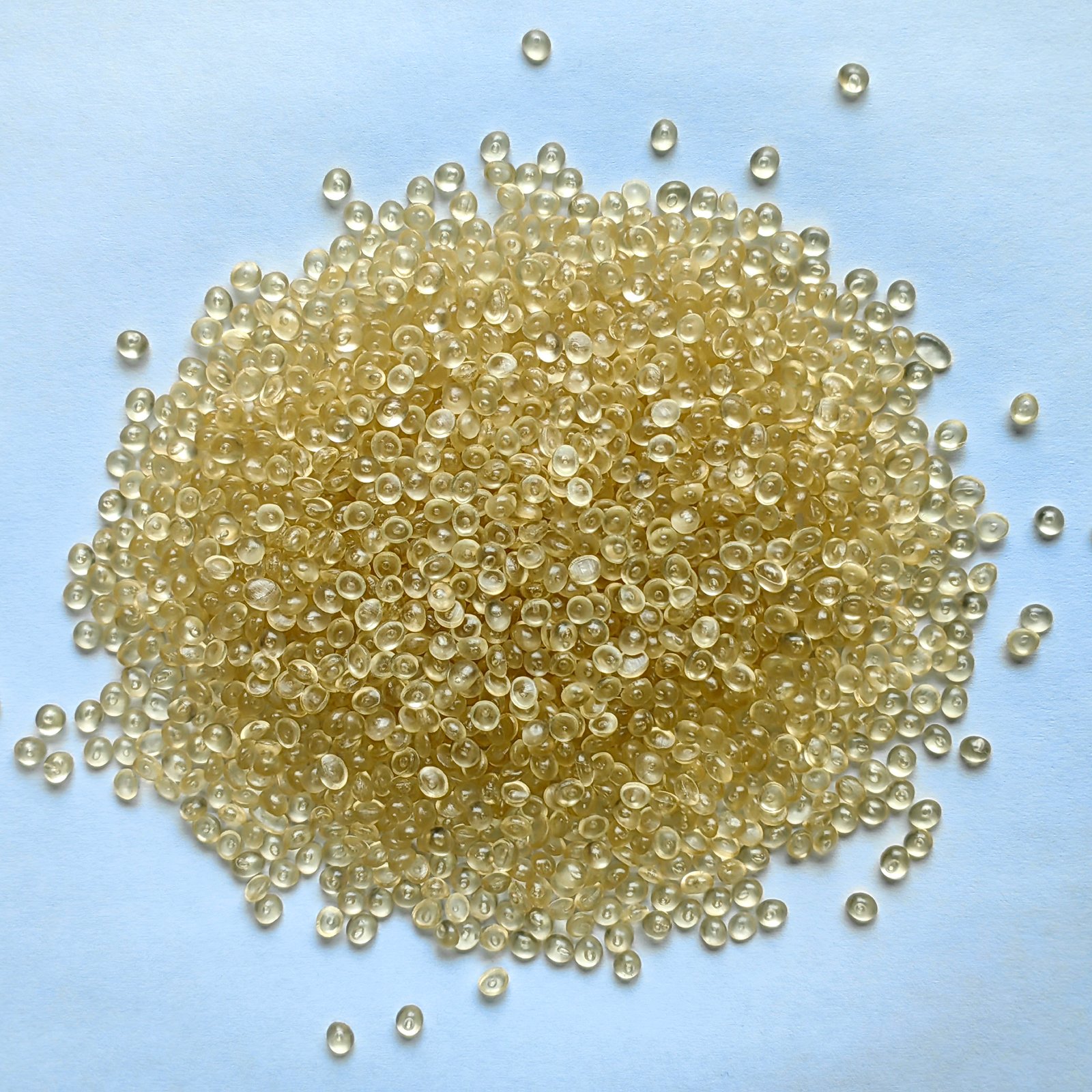

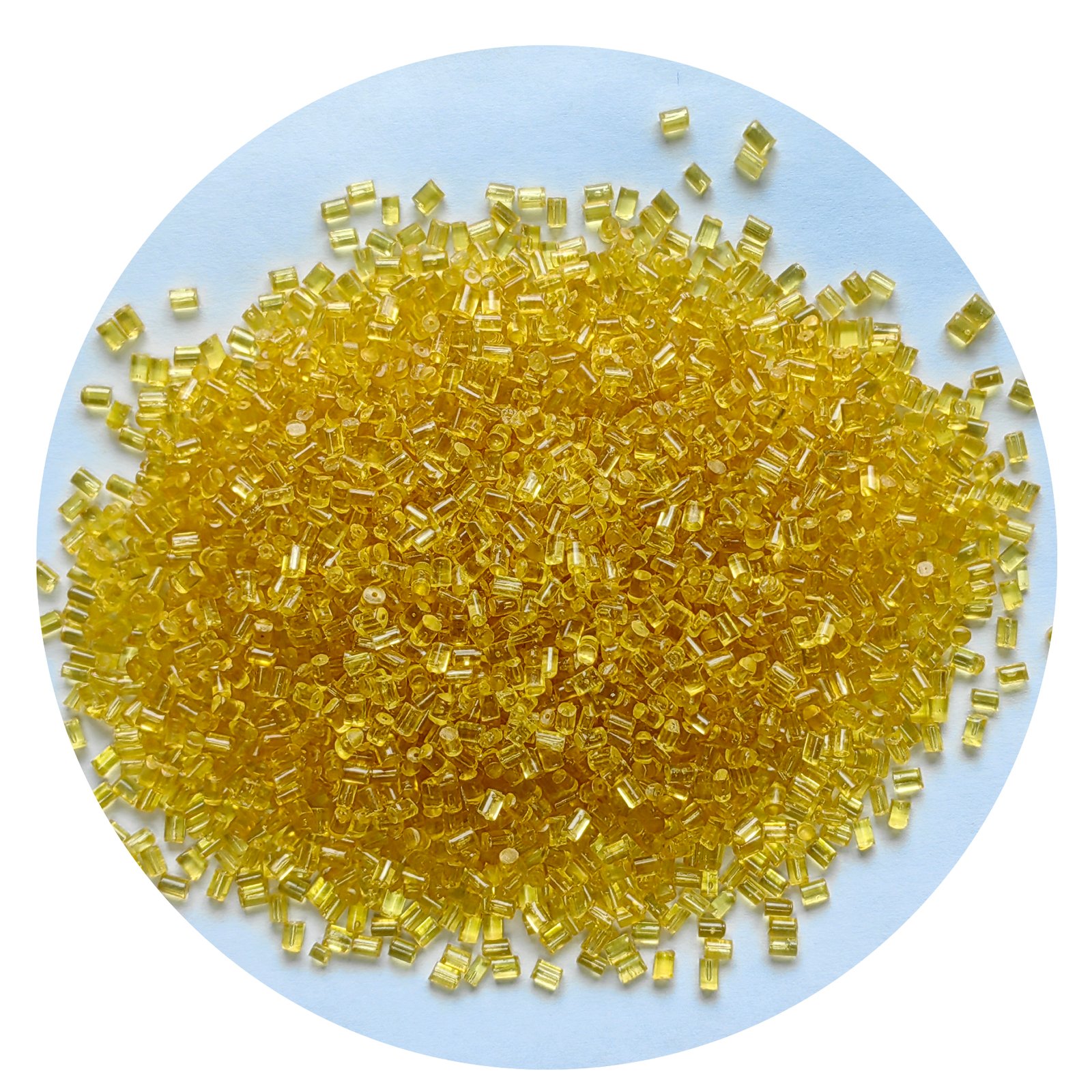

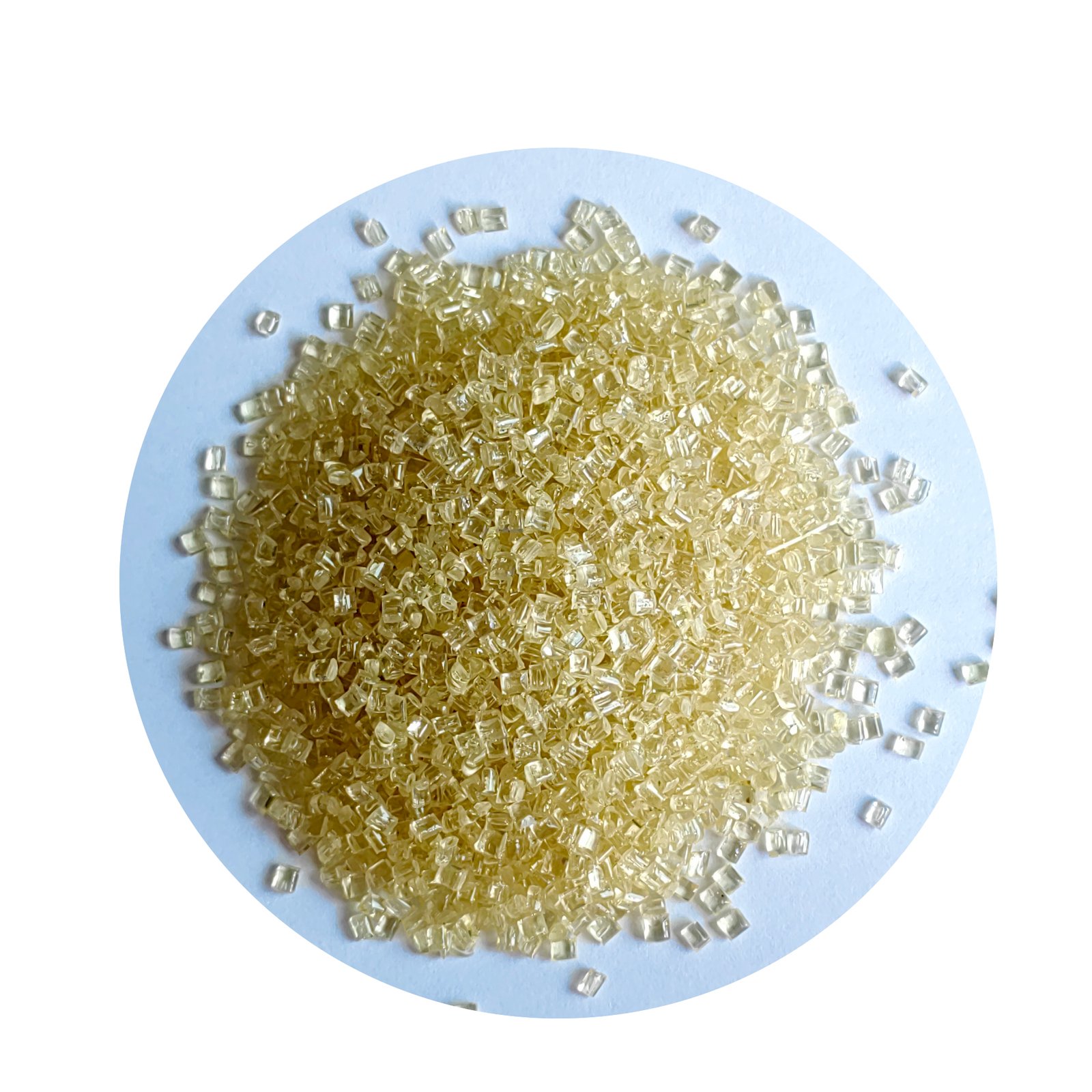

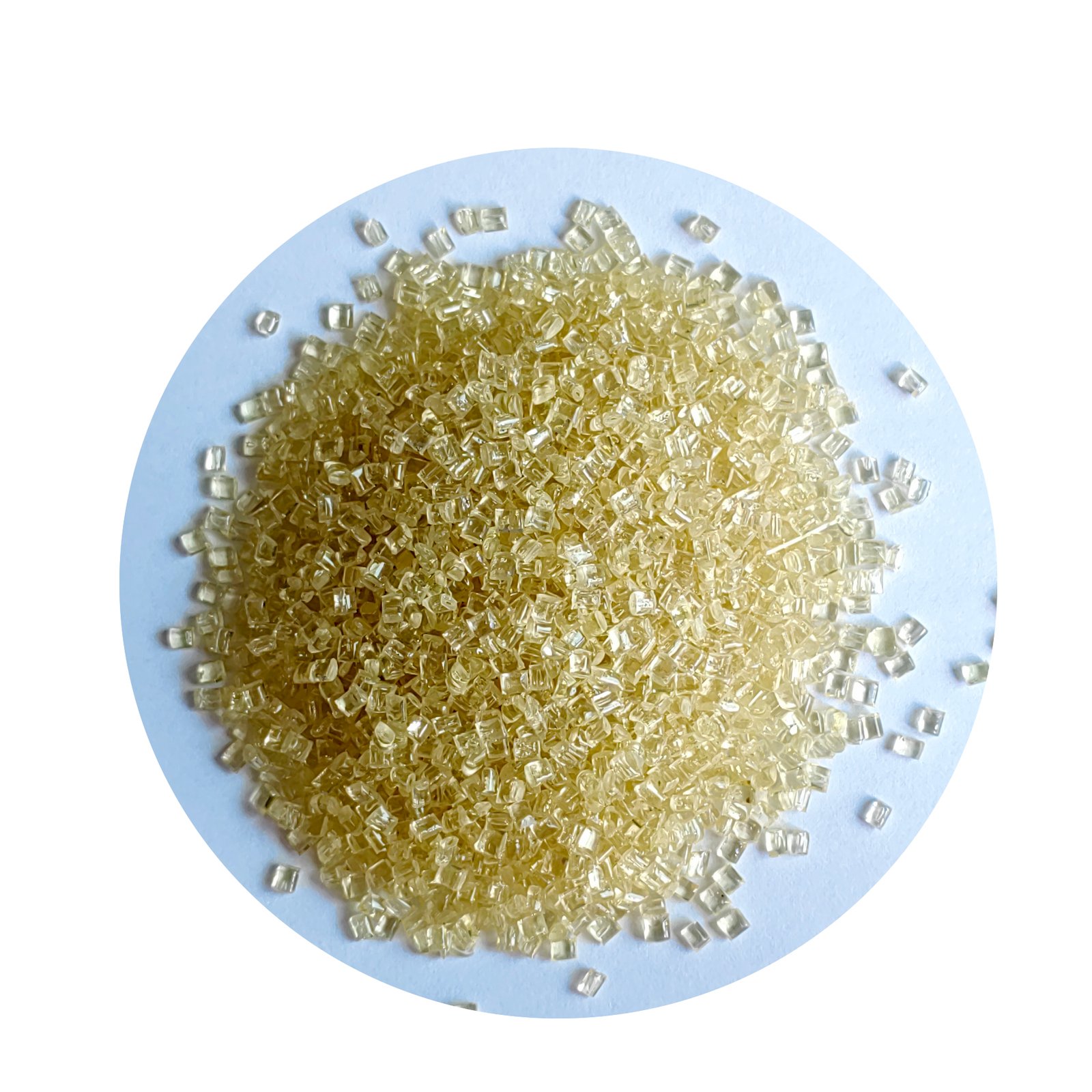

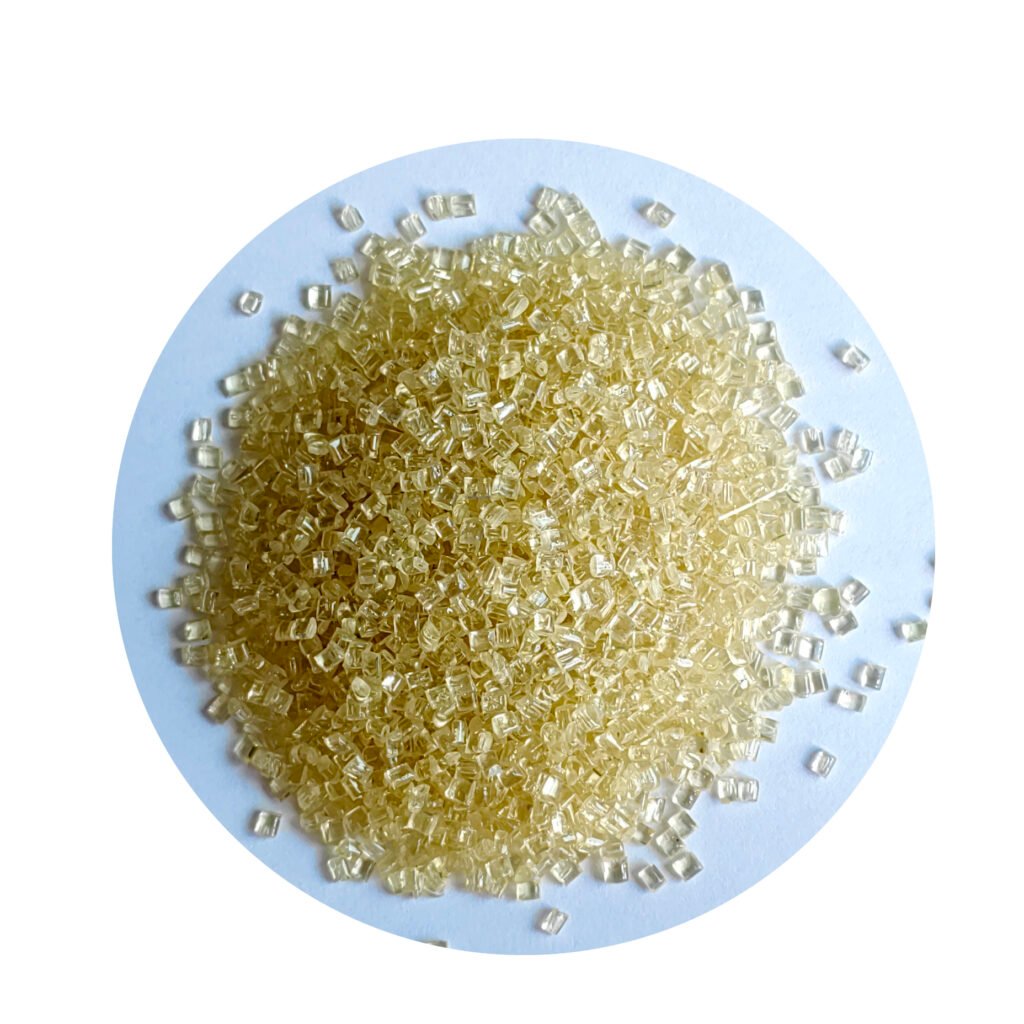

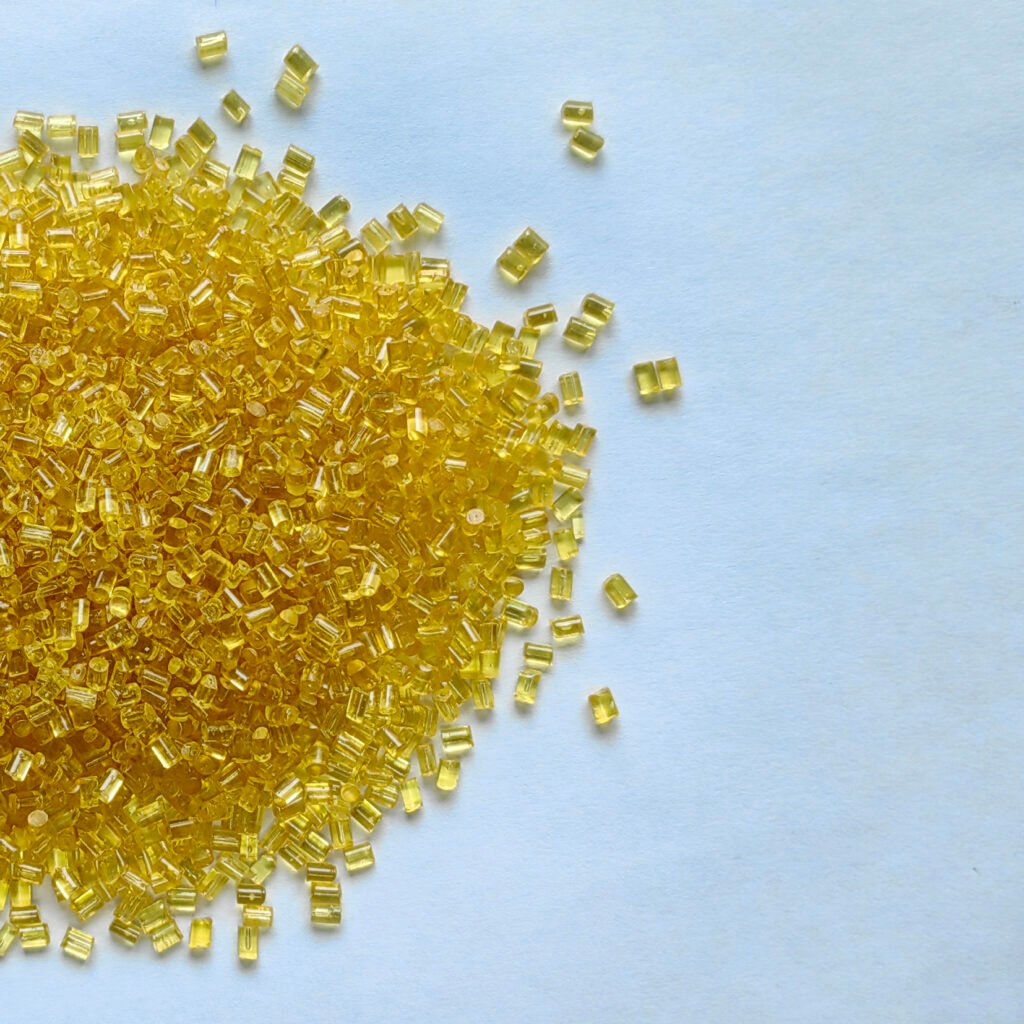

PESU 2010 G4 20% Glass Fiber Reinforced PES Polyethersulfone

Productconstructie

What is PES Polyethersulfone

In high-precision manufacturing fields such as electrical appliances, printing equipment, and industrial structural components, a composite requirement of "lightweight + high strength + thermal stability + flame retardancy and environmental protection" is put forward for materials. PESU 2010 G4, as a 20% glass fiber reinforced pes polyethersulfone material developed by BASF, is becoming an important force in the field of engineering plastics with its outstanding mechanical, electrical and thermal properties.

01 | Why is PESU 2010 G4 of greater strategic value in the current industry?

With the continuous enhancement of demands for high-temperature durability, high-frequency insulation, and structural reliability, materials are no longer merely "qualified in performance". They must meet the requirements of multi-dimensional working conditions for coordinated adaptation

・High rigidity and structural strength: tensile modulus up to 6900 MPa, tensile strength up to 130 MPa, suitable for load-bearing structural parts such as electrical components, brackets and housings;

・Excellent thermal stability: The heat distortion temperature can reach up to 222°C, and the long-term temperature resistance of RTI can be as high as 190°C, making it suitable for continuous high-temperature environments.

・Flame retardant grade V-0:1.5mm and 3.0mm thickness of UL94 V-0, no halogen environmental protection;

・Electrical safety and reliability: volume resistance 1E15Ω ·cm, CTI grade 125V, meet the insulation requirements of medium and high voltage electrical appliances;

・Strong dimensional stability: low shrinkage (0.36% in flow direction, 0.61% in lateral direction), suitable for parts with high precision requirements.

These advantages make the PESU 2010 G4 a reliable choice for printing equipment core components, electrical enclosures, industrial heat connectors and other scenarios.

02 | Typical Application Scenarios: Specifically designed for printing equipment and electrical structural components

PESU 2010 G4 is widely used in the following occasions:

・Printer components: including guide rails, gear brackets, support beams and other structural parts that require high rigidity and thermal stability;

・Electronic and electrical components: Suitable for long-term energized structures such as circuit breaker housings, terminal seats, and insulating bases;

・Industrial precision parts: They are also widely used in structural support or snap-fit components where dimensional stability is required.

Due to the material's excellent processability and low warpage characteristics, it is particularly suitable for batch injection molding, meeting the efficiency requirements of high-speed production lines.

03 | Processing and Usage Suggestions

・Recommended process: Injection molding. It is suggested that the mold temperature be controlled at 120-160°C and the melt temperature be around 360°C.

・Drying recommendation: drying at 120°C for at least 4 hours before molding to reduce the influence of water absorption;

・Mold design: due to the high strength of the material, the mold should have good wear resistance, and appropriately increase the demoulding slope;

・Post-processing application environment recommendation:Avoid long-term exposure to high humidity and strong acid environments. Although the material is heat-resistant, the water absorption rate is below 1.6% at saturation.

04 | PESU 2010 G4 Polyethersulfone Datasheet

| UL | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CTI | EN 60112 | 4 | BV | ||||

| HWI | Alle kleuren 1,5 mm | UL746A | 0 | BV | |||

| HWI | Alle kleuren 3,0 mm | UL746A | 0 | BV | |||

| RTI | Elec Alle Kleuren 1.5mm | UL 746B | 180 | °C | |||

| RTI | Str Alle kleuren 3,0 mm | UL 746B | 190 | °C | |||

| Vlamclassificatie | Alle kleuren 1,5 mm | UL94 | V-0 | ||||

| Vlamclassificatie | Alle kleuren 3,0 mm | UL94 | V-0 | ||||

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | Pauze 23°C | ISO527 | 3.2 | % | |||

| Izod Notch-impact | 23°C | ISO180 | 8.0 | kJ/m² | |||

| Izod Notch-impact | -30°C | ISO180 | 8.0 | kJ/m² | |||

| Treksterkte | Pauze 23°C | ISO527 | 130 | MPa | |||

| Trekmodulus | 23°C | ISO527 | 6900 | MPa | |||

| Charpy Un-notch-impact | 23°C | ISO179 | 60 | kJ/m² | |||

| Charpy Notch-impact | -30°C | ISO179 | 8.0 | kJ/m² | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| HDT | Niet-gegloeid 1,8 MPa | ISO75 | 222 | °C | |||

| CLE | Stroom | 2E-5 | cm/cm/°C | ||||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Wateropname | 23°C Verzadiging | ISO62 | 1.6 | % | |||

| Wateropname | 23°C 50RH Balance | ISO62 | 0.60 | % | |||

| Krimp | Stroom | ISO294 | 0.36 | % | |||

| Krimp | xFlow | ISO294 | 0.61 | % | |||

| Dikte | ISO1183 | 1.50 | g/cm³ | ||||

| Smeltindex | 360°C 10kg | ISO1133 | 29 | cm³/10min | |||

| Elektrische eigenschappen | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CTI | EN 60112 | 125 | V | ||||

| Diëlektrische constante | 1 MHz | EN 60250-norm | 4.20 | ||||

| Diëlektrische constante | 100Hz | EN 60250-norm | 4.20 | ||||

| Volumeweerstand | IEC 60093 | 1E15 | Ω.cm | ||||

| Diëlektrische sterkte | IEC 60243 | 37 | kv/mm | ||||

| Dissipatiefactor | 1 MHz | EN 60250-norm | 0.010 | ||||

| Dissipatiefactor | 100Hz | EN 60250-norm | 0.002 | ||||

| Oppervlakteweerstand | IEC 60093 | 1E15 | Ω | ||||

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Hardheid van de kogelindrukking | ISO2039 | 205 | MPa | ||||

| Ontvlambaarheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Vlamclassificatie | Alle kleuren 1,5 mm | UL94 | V-0 | ||||

| Vlamclassificatie | Alle kleuren 3,0 mm | UL94 | V-0 | ||||

05 | Industry Trends: Why Reinforced PES Polyethersulfone Is Gaining Importance?

PESU 2010 G4 is increasingly demonstrating its value in addressing shifting industrial demands across key sectors:

| Industry Trend | How PESU 2010 G4 Responds |

| Localization of high-reliability electronic components | High dielectric strength and thermal stability make it suitable for domestically produced electrical control components |

| Stricter green flame-retardant regulations | Halogen-free formulation that complies with RoHS and REACH, supporting compliant export requirements |

| Lightweight integration in smart industrial equipment | High strength and low density enable metal part substitution, improving energy efficiency and system responsiveness |

| Premiumization of printing and office equipment | High surface hardness (ball indentation hardness: 205 MPa) and dimensional stability meet the demands of high-speed operation and precision assembly |

06 | FAQ: Frequently Asked Questions

Q1: Is PESU 2010 G4 suitable as a substitute for metals?

A: This material can be used to partially replace metal parts (such as electronic skeletons) with low structural load bearing but high requirements for thermal stability and dimensional accuracy, reducing weight and improving insulation safety.

Q2: this material is suitable for which customer group?

A: Mainly aimed at printer manufacturers, electrical system integrators, and industrial customers with special needs for high temperature and high strength plastics.

Q3: What kind of support does your company provide?

A: As a professional supplier of plastic raw materials, Juyuan Plasticizer (juyuans.com) can provide:

・Fast model recommendation and sample delivery

・Process parameters consulting and selection Suggestions

・Combined with the project demand comparison selection service, help customers shorten the R&D cycle.

Q4: if I'm not familiar with G4 PESU 2010, can you test first?

A: Yes.We provide standard sample package and support technical consultation in the stage of small batch mold trial to ensure more reliable material selection.

07 | More recommended models: Explore the diverse performance possibilities of PESU materials

If PESU 2010 G4 meets your needs in terms of rigidity and heat resistance, but the project also involves conductivity, processing flexibility or special structural parts requirements, the following polyethersulfone materials from BASF are also worth paying attention to:

| Fabrikant | Materiaal | Grade | Dikte | Melt Flow Index | Trekmodulus | Treksterkte | Rek bij breuk |

| BASF | PESU | Dimension E1010 G9 | 1.37 g/cm³ | 35 cm³/10min | 15,500 MPa | 145 MPa | 1.3% |

| BASF | PESU | 2020 P | — | — | 2,650 MPa | 85 MPa | 6.9% |

| BASF | PESU | 2020 P SR micro | — | — | — | — | — |

Each PESU polyethersulfone material embodies the coordinated optimization of functionality and processability, and can be flexibly selected according to project requirements to achieve full process support from performance improvement to structural innovation.

08 | Conclusion

PESU 2010 G4 is not only an engineering plastic with excellent data, but also an ideal choice for high-end manufacturing to meet the needs of stability, strength and environmentally friendly flame retardant. Facing increasingly complex applications of electrical and electronic structural components, it helps products become safer and more durable with its stable performance and high reliability.

If you are looking for high-performance, flame-retardant reinforced pes polyethersulfone materials, you are welcome to visit our official website juyuans.com for more technical information and recommended models.

【Gerelateerde aanbevelingen】

PESU 7020 P: Flake-Form pes plastic material for High-Performance Coating Applications Meer informatie>

PESU 3010 MR UN: High-Viscosity PES Plastic for Medical & Rail Applications Meer informatie>

PESU 2010 HC: Flame-Retardant PES Material for Medical and Electronic Applications Meer informatie>