PRODUCTEN

LUVOCOM® Polyether Ether Ketone for Bearings ans Gears

Productconstructie

What is Polyether Ether Ketone

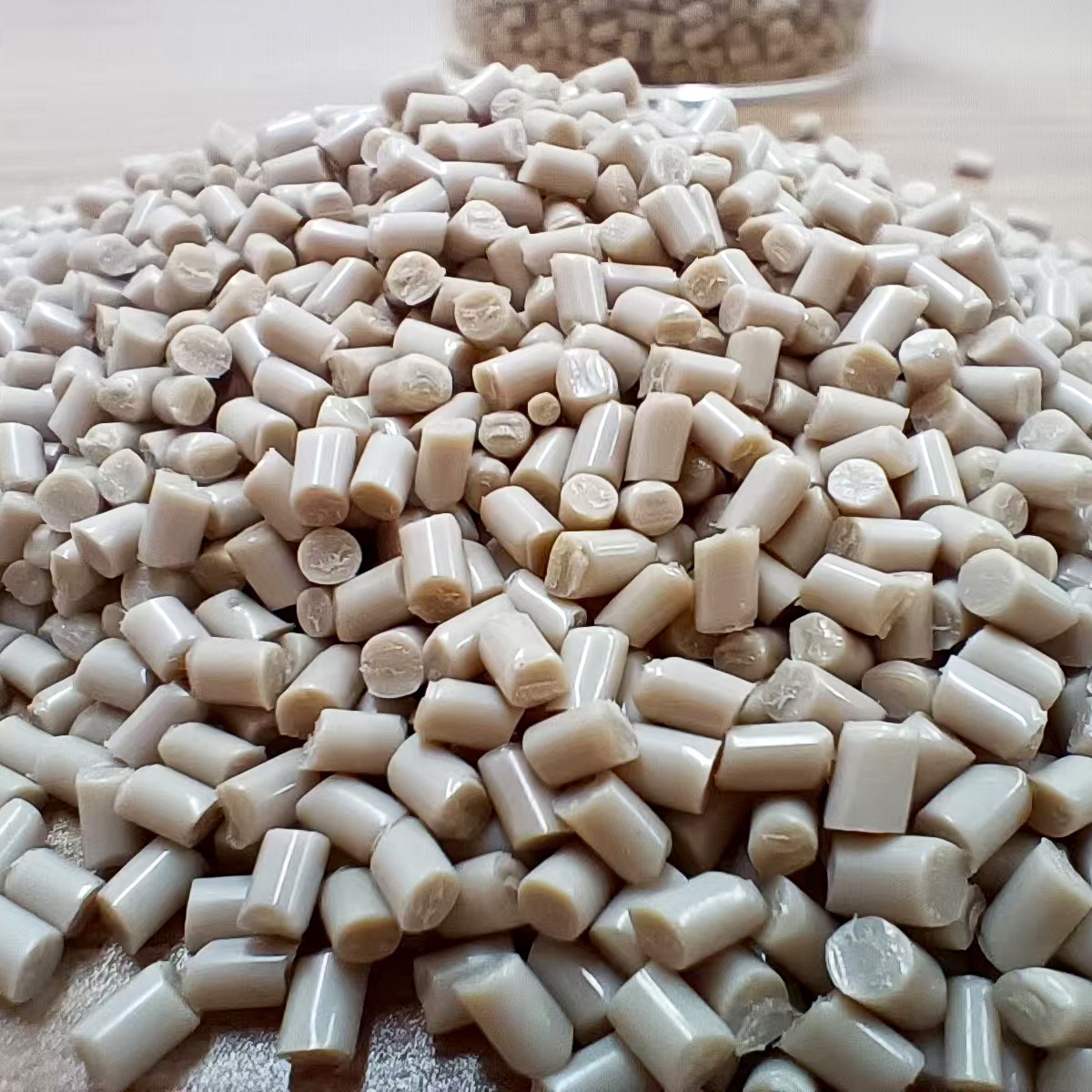

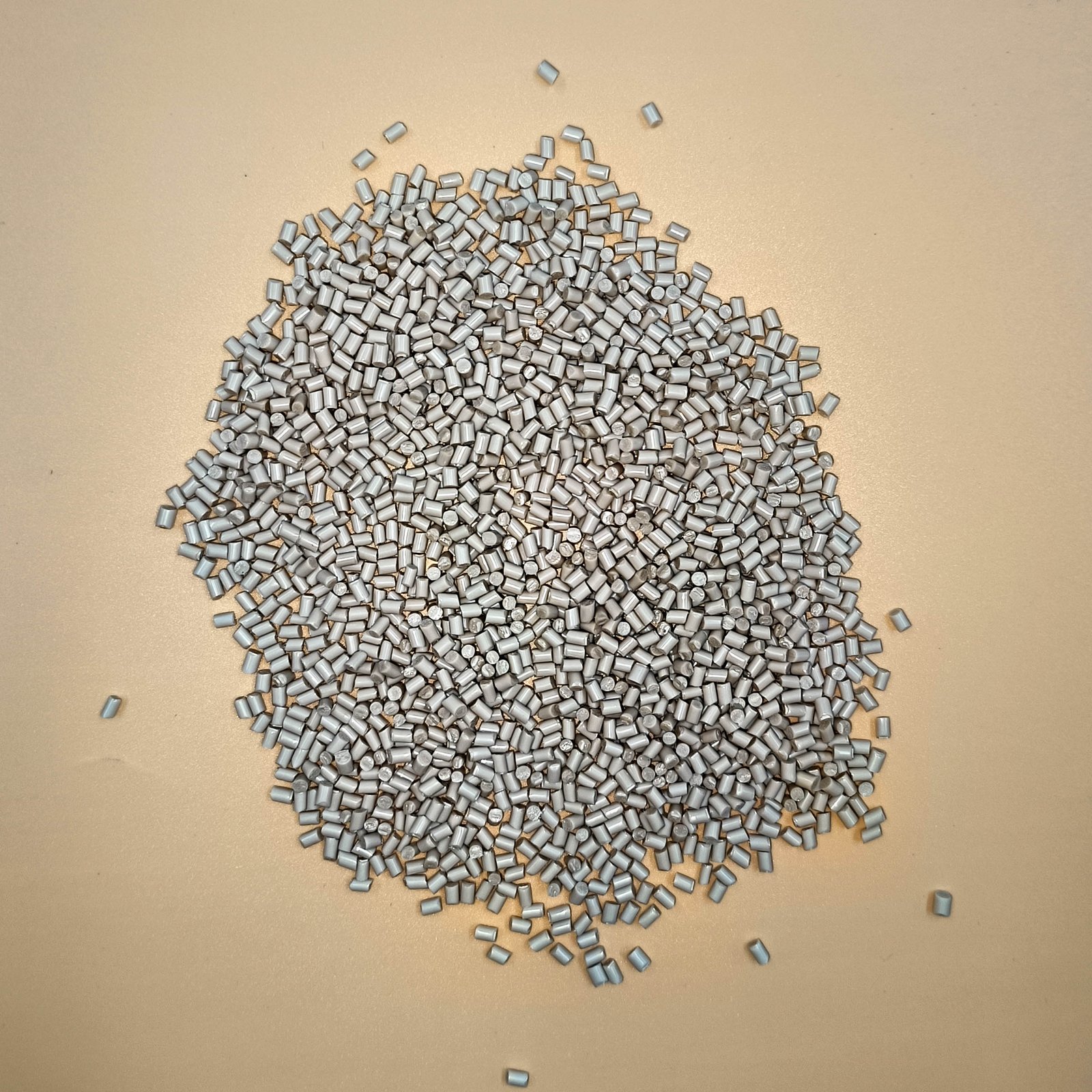

The LUVOCOM® Polyether Ether Ketone (PEEK) series developed by Lehmann & Voss is a representative engineering plastic material for mechanical components with high friction and high load. With its outstanding mechanical strength, thermal stability and wear resistance, this series of products are widely used in long-term operation scenarios such as bearings, gears and sliding components, meeting the strict requirements of industrial equipment for durability and dimensional accuracy.

01 | Common Features of LUVOCOM® Polyether Ether Ketone Series

The LUVOCOM® PEEK series is not a single model, but a group of Polyether Ether Ketone materials optimized and modified for different applications. They differ in formula and enhancement system, but they all share the following commonalities:

・Outstanding wear resistance and low friction performance: Significantly reduces energy consumption and wear, and extends service life.

・Excellent thermal stability: It can be used for a long time at 260-300 °C without losing its shape.

・Excellent dimensional stability: Low creep and low thermal expansion ensure high-precision gear meshing and stable bearing clearance.

・Chemical resistance and hydrolysis resistance: It can maintain performance in complex media such as lubricating oil, fuel, and steam.

・Diversified modification system: By adding carbon fiber, graphite or PTFE, higher wear resistance and self-lubrication effects are achieved.

02 | Suggestions for Processing and Forming

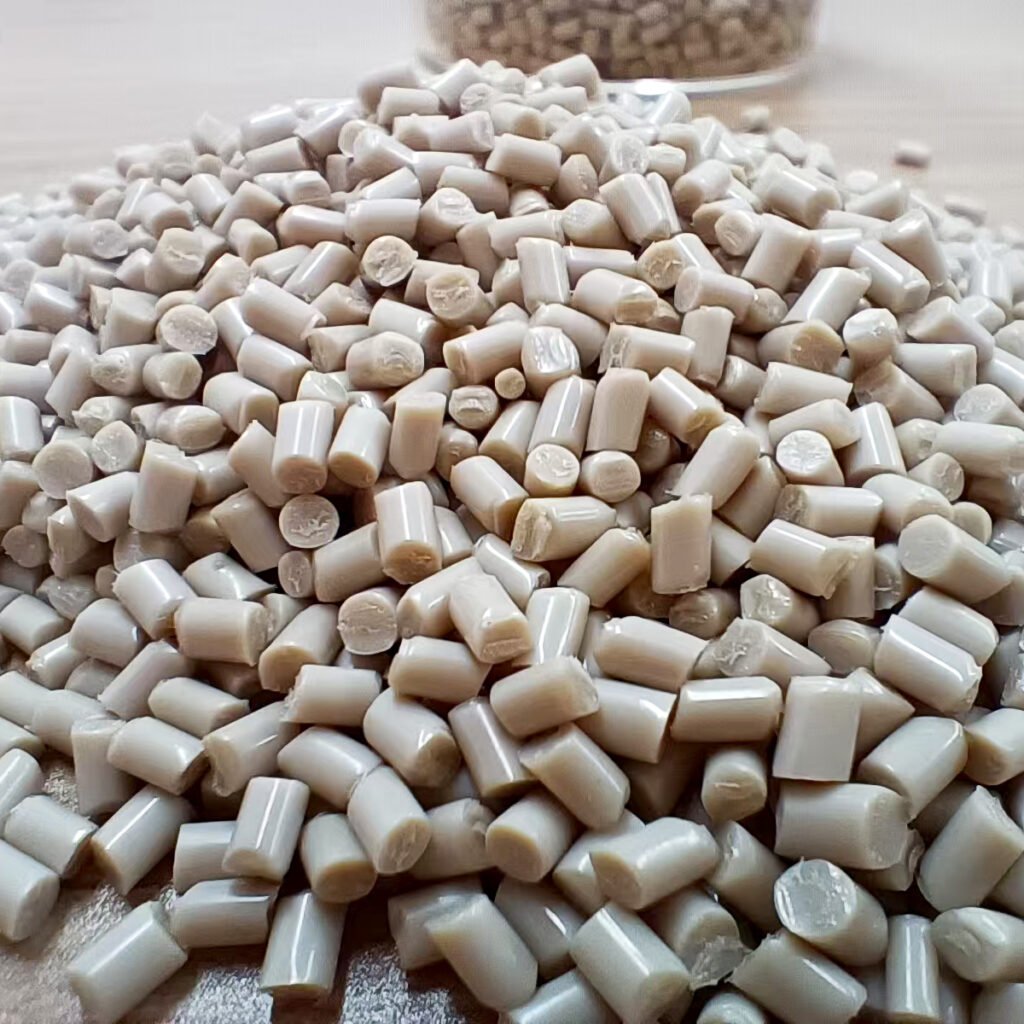

The LUVOCOM® Polyether Ether Ketone series can be applied to spuitgieten en extrusiegieten processes. The melt fluidity and shrinkage rate of different models vary slightly. The appropriate model can be selected based on the product structure.

It is recommended to control the melt flow within the processing temperature range of 360-400 °C and thoroughly dry it before molding to ensure the surface quality and internal density of the product.

03 | Typical Application Scenarios

Thanks to its comprehensive performance, the LUVOCOM® Polyether Ether Ketone series performs outstandingly in the following fields:

・Bearings and bushings: Maintain low friction and low wear, suitable for continuous operation systems.

・Gears and transmission parts: Ensure long-term meshing accuracy and quiet operation.

・Automotive and industrial power systems: It can maintain strength and rigidity in high-temperature and high-load environments.

・Compressor and pump parts: steam-resistant, corrosion-resistant, suitable for high-temperature and high-pressure environments.

04 | List of Product Series

The following are the representative models of the LUVOCOM® Polyether Ether Ketone series suitable for bearing and gear applications, covering different reinforcing systems and flow properties, facilitating customers to select according to the working conditions.

| Productmodel | Dikte | Melt Flow Index | Treksterkte | Verlenging | Krimp | Smelttemperatuur | Vicat-verzachtingstemperatuur | Buigmodulus | Coefficient of Linear Expansion | Buigsterkte |

| 1105-9254 | 1.48 g/cm³ | 55 MPa | 4 % | 0.6 % | 3000 MPa | 95 MPa | ||||

| 1105-8350 | 1.44 g/cm³ | 21.6 g/10min | 155 MPa | 2 % | 0.2 % | 260 ℃ | 300 ℃ | 9000 MPa | 3E-5 cm/cm/℃ | 210 MPa |

| 1105-8422 | 1.45 g/cm³ | 60 g/10min | 150 MPa | 2.2 % | 0.2 % | 260 ℃ | 9000 MPa | 200 MPa | ||

| 1105-8319 | 1.34 g/cm³ | 30 g/10min | 65 MPa | 3 % | 1 % | 2500 MPa | 85 MPa | |||

| 1105-8004 | 1.4 g/cm³ | 175 MPa | 2 % | 0.2 % | 14000 MPa | 255 MPa | ||||

| 1105-8169 | 1.46 g/cm³ | 17.52 g/10min | 175 MPa | 2 % | 0.3 % | 265 ℃ | 13000 MPa | 250 MPa | ||

| 1105-7825 | 1.41 g/cm³ | 80 MPa | 7 % | 1 % | 280 ℃ | 2500 MPa | 110 MPa | |||

| 1105-7852 | 1.42 g/cm³ | 240 MPa | 1.5 % | 0.1 % | 20000 MPa | 340 MPa | ||||

| 1105-0706 | 1.49 g/cm³ | 170 MPa | 3.5 % | 0.3 % | 315 ℃ | 320 ℃ | 7000 MPa | 2.1E-5 cm/cm/℃ | 250 MPa | |

| 1105-7041 | 1.45 g/cm³ | 245 MPa | 1.4 % | 0.06 % | 260 ℃ | 320 ℃ | 26000 MPa | 7E-6 cm/cm/℃ | 355 MPa | |

| 1105-7096 | 1.42 g/cm³ | 240 MPa | 1.5 % | 0.05 % | 21000 MPa | 350 MPa | ||||

| 1105-7327 | 1.82 g/cm³ | 12.74 g/10min | 160 MPa | 1.3 % | 0.1 % | 17000 MPa | 250 MPa | |||

| 1105-7685 | 1.29 g/cm³ | 20 g/10min | 100 MPa | 5 % | 1 % | 300 ℃ | 3000 MPa | 145 MPa | ||

| 1105-7766 | 1.42 g/cm³ | 21.3 g/10min | 260 MPa | 1.6 % | 0.05 % | 260 ℃ | 320 ℃ | 22950 MPa | 9E-6 cm/cm/℃ | 375 MPa |

| 1105-7777 | 1.56 g/cm³ | 29.64 g/10min | 95 MPa | 3 % | 0.7 % | 5000 MPa | 135 MPa | |||

| 1105-8529 | 1.39 g/cm³ | 240 MPa | 2.2 % | 0.1 % | 18000 MPa | 345 MPa | ||||

| 1105-8592 | 1.65 g/cm³ | 210 MPa | 2.2 % | 0.2 % | 325 ℃ | 15000 MPa | 1.9E-5 cm/cm/℃ | 265 MPa | ||

| 1105-8737 | 1.38 g/cm³ | 75 MPa | 6 % | 1 % | 280 ℃ | 2500 MPa | 100 MPa | |||

| 1105-9234 | 1.8 g/cm³ | 135 MPa | 1.4 % | 0.1 % | 325 ℃ | 14000 MPa | 195 MPa | |||

| 1105-1330 | 1.36 g/cm³ | 20 g/10min | 85 MPa | 6 % | 1 % | 3000 MPa | 115 MPa | |||

| 7980 VP | 1.41 g/cm³ | 235 MPa | 1.6 % | 0.05 % | 315 ℃ | 21000 MPa | 9E-6 cm/cm/℃ | 340 MPa | ||

| 1105-7442 | 1.36 g/cm³ | 210 MPa | 2 % | 0.2 % | 15000 MPa | 1.6E-5 cm/cm/℃ | 295 MPa | |||

| 1105-7740 | 1.33 g/cm³ | 20 g/10min | 96 MPa | 5 % | 0.5 % | 280 ℃ | 3400 MPa | 140 MPa | ||

| 1105-7760 | 1.64 g/cm³ | 10 g/10min | 130 MPa | 1.8 % | 0.3 % | 260 ℃ | 320 ℃ | 10000 MPa | 185 MPa | |

| 1105-7835 | 1.69 g/cm³ | 75 MPa | 2 % | 0.7 % | 7000 MPa | 105 MPa | ||||

| 1105-7907 | 1.33 g/cm³ | 175 MPa | 3.1 % | 0.3 % | 8500 MPa | 245 MPa | ||||

| 1105-7995 | 1.52 g/cm³ | 91.2 g/10min | 240 MPa | 1.4 % | 0.05 % | 20000 MPa | 445 MPa | |||

| 1105-8065 | 1.36 g/cm³ | 32.64 g/10min | 200 MPa | 2.3 % | 0.2 % | 11000 MPa | 295 MPa | |||

| 1105-8179 | 1.45 g/cm³ | 280 MPa | 1.3 % | 0.05 % | 330 ℃ | 27000 MPa | 405 MPa | |||

| 1105-8234 | 1.42 g/cm³ | 10 g/10min | 195 MPa | 1.5 % | 0.1 % | 15000 MPa | 270 MPa | |||

| 1105-8355 | 1.47 g/cm³ | 240 MPa | 1.4 % | 0.05 % | 325 ℃ | 25000 MPa | 345 MPa | |||

| 1105-7907 VP | 1.33 g/cm³ | 175 MPa | 3.1 % | 0.3 % | 8500 MPa | 245 MPa | ||||

| 1105-7536 | 1.45 g/cm³ | 240 MPa | 1.6 % | 0.06 % | 260 ℃ | 320 ℃ | 25000 MPa | 340 MPa | ||

| 1105-7741 | 1.32 g/cm³ | 15 g/10min | 92 MPa | 5 % | 0.5 % | 280 ℃ | 3600 MPa | 130 MPa | ||

| 1105-7905 | 1.37 g/cm³ | 215 MPa | 2.2 % | 0.2 % | 14000 MPa | 310 MPa | ||||

| 1105-7916 | 1.34 g/cm³ | 160 MPa | 2.5 % | 0.2 % | 8500 MPa | 235 MPa | ||||

| 1105-8102 | 1.4 g/cm³ | 37 g/10min | 65 MPa | 2.8 % | 1 % | 2500 MPa | 90 MPa | |||

| 1105-8161 | 1.45 g/cm³ | 45 g/10min | 180 MPa | 1.8 % | 0.3 % | 260 ℃ | 295 ℃ | 12000 MPa | 260 MPa | |

| 1105-8173 | 1.48 g/cm³ | 80 MPa | 6 % | 0.9 % | 2500 MPa | 110 MPa | ||||

| 1105-8354 | 1.43 g/cm³ | 265 MPa | 1.6 % | 0.05 % | 325 ℃ | 24000 MPa | 380 MPa | |||

| 1105/GF/30/TF/15 | 1.63 g/cm³ | 145 MPa | 2 % | 0.2 % | 315 ℃ | 315 ℃ | 8000 MPa | 2.2E-5 cm/cm/℃ | 160 MPa | |

| 1105-9012/T | 1.44 g/cm³ | 10 g/10min | 140 MPa | 1.7 % | 0.2 % | 260 ℃ | 300 ℃ | 10000 MPa | 3E-5 cm/cm/℃ | 205 MPa |

| 1105-9020/T | 1.62 g/cm³ | 15 g/10min | 155 MPa | 1.6 % | 0.2 % | 260 ℃ | 320 ℃ | 13000 MPa | 215 MPa | |

| 1105-7670/BL | 1.46 g/cm³ | 75 MPa | 6.5 % | 1 % | 2500 MPa | 105 MPa | ||||

| 1105-8389/BL | 1.59 g/cm³ | 145 MPa | 2 % | 0.3 % | 315 ℃ | 325 ℃ | 9000 MPa | 2.2E-5 cm/cm/℃ | 205 MPa | |

| 1105-7781 | 1.43 g/cm³ | 14.3 g/10min | 240 MPa | 1.8 % | 0.1 % | 260 ℃ | 22000 MPa | 9E-6 cm/cm/℃ | 350 MPa | |

| 1105-8002 | 1.4 g/cm³ | 84 g/10min | 295 MPa | 1.8 % | 0.05 % | 23000 MPa | 425 MPa | |||

| 1105-8199 | 1.33 g/cm³ | 95 MPa | 2.5 % | 1 % | 4500 MPa | 175 MPa | ||||

| 1105-9232 | 1.36 g/cm³ | 7 g/10min | 200 MPa | 2.1 % | 0.2 % | 13000 MPa | 290 MPa | |||

| 1105-7751 | 1.45 g/cm³ | 270 MPa | 1.2 % | 0.05 % | 260 ℃ | 320 ℃ | 28000 MPa | 7E-6 cm/cm/℃ | 390 MPa | |

| 1105-7506 | 1.36 g/cm³ | 122.4 g/10min | 195 MPa | 2.2 % | 0.3 % | 13000 MPa | 275 MPa | |||

| 1105-8487 | 1.32 g/cm³ | 90 MPa | 4 % | 0.5 % | 4200 MPa | 130 MPa | ||||

| 1105-7536 VP | 1.45 g/cm³ | 240 MPa | 1.6 % | 0.06 % | 260 ℃ | 320 ℃ | 25000 MPa | 340 MPa | ||

| 1105-7731/BL | 1.76 g/cm³ | 115 MPa | 1.4 % | 0.4 % | 11000 MPa | 165 MPa | ||||

| 1105-8135/VI | 1.31 g/cm³ | 100 MPa | 4.5 % | 1 % | 3000 MPa | 140 MPa | ||||

| 1105/GF/40/BK-1 | 1.61 g/cm³ | 180 MPa | 2 % | 0.3 % | 325 ℃ | 11000 MPa | 250 MPa | |||

| 1105-8048 | 1.51 g/cm³ | 280 MPa | 0.9 % | 0.05 % | 330 ℃ | 41000 MPa | 400 MPa | |||

| 105/XCF/20 | 1.37 g/cm³ | 270 MPa | 2.3 % | 0.06 % | 18000 MPa | 390 MPa | ||||

| 1105-7914 | 1.35 g/cm³ | 160 MPa | 3.5 % | 0.2 % | 9000 MPa | 235 MPa | ||||

| 1105-8455 | 1.39 g/cm³ | 175 MPa | 2.1 % | 0.2 % | 260 ℃ | 320 ℃ | 15000 MPa | 255 MPa | ||

| 1105/GF/20/EM/RD | 1.45 g/cm³ | 15 g/10min | 140 MPa | 2.5 % | 0.3 % | 285 ℃ | 325 ℃ | 7000 MPa | 3E-5 cm/cm/℃ | 190 MPa |

| 1105-8513 | 1.42 g/cm³ | 245 MPa | 1.6 % | 0.05 % | 260 ℃ | 325 ℃ | 22000 MPa | 9E-6 cm/cm/℃ | 360 MPa | |

| 1105-8783 | 1.51 g/cm³ | 90 MPa | 2 % | 0.6 % | 7400 MPa | 100 MPa | ||||

| 1105/CF/30/EM/L | 1.42 g/cm³ | 220 MPa | 1.3 % | 0.05 % | 260 ℃ | 325 ℃ | 21000 MPa | 9E-5 cm/cm/℃ | 320 MPa | |

| 1105/MS/15/TF/15 | 1.55 g/cm³ | 80 MPa | 5 % | 0.7 % | 280 ℃ | 3500 MPa | 5E-5 cm/cm/℃ | 120 MPa | ||

| 1105-8320 | 1.34 g/cm³ | 5 g/10min | 75 MPa | 3.3 % | 0.8 % | 2500 MPa | 85 MPa | |||

| 1105-7290 | 1.46 g/cm³ | 215 MPa | 0.9 % | 0.05 % | 30000 MPa | 320 MPa | ||||

| 1105-8417 | 1.42 g/cm³ | 245 MPa | 1.7 % | 0.05 % | 260 ℃ | 325 ℃ | 21000 MPa | 370 MPa | ||

| 1105-7141 | 1.4 g/cm³ | 210 MPa | 1.6 % | 0.1 % | 19000 MPa | 300 MPa | ||||

| 1105-8168 | 1.55 g/cm³ | 15.5 g/10min | 180 MPa | 1.8 % | 0.2 % | 265 ℃ | 15000 MPa | 260 MPa | ||

| 1105-7251 | 1.84 g/cm³ | 15 g/10min | 90 MPa | 1.5 % | 0.4 % | 330 ℃ | 13000 MPa | 2.2E-5 cm/cm/℃ | 160 MPa | |

| 1105-0948/YL2 | 1.56 g/cm³ | 135 MPa | 2.2 % | 0.3 % | 285 ℃ | 320 ℃ | 7000 MPa | 190 MPa | ||

| 1105-7373 | 1.62 g/cm³ | 12 g/10min | 145 MPa | 1.8 % | 0.3 % | 260 ℃ | 320 ℃ | 11000 MPa | 200 MPa | |

| 1105-9254 | 1.48 g/cm³ | 55 MPa | 4 % | 0.6 % | 3000 MPa | 95 MPa |

05 | Juyuan: A reliable international Partner for plastic raw materials

Juyuan is a supplier specializing in international trade of plastic raw materials. With 24 years of industry experience, it has long provided high-performance engineering plastics including LUVOCOM® Polyether Ether Ketone to global customers.

We offer our customers

・Stable international channels and rapid delivery services;

・Professional selection guidance and technical support;

・Flexible trade plans and long-term cooperation guarantees.

Choose Juyuan and you will enjoy reliable supply guarantees and technical support, making your project more competitive.

【Gerelateerde aanbevelingen】

Film Blowing Process & Defect Solutions | Resin Supplier Meer informatie>

PEEK 450G | Medical & Food Contact Applications PEEK Plastic Meer informatie>

ARLON® 1330 | PEEK For Semiconductor Molding Applications Meer informatie>