PRODUCTEN

LUVOCOM® 3F PEEK CF 9676 BK: Chemical-Resistant PEEK Polymers

Productconstructie

What are PEEK Polymers

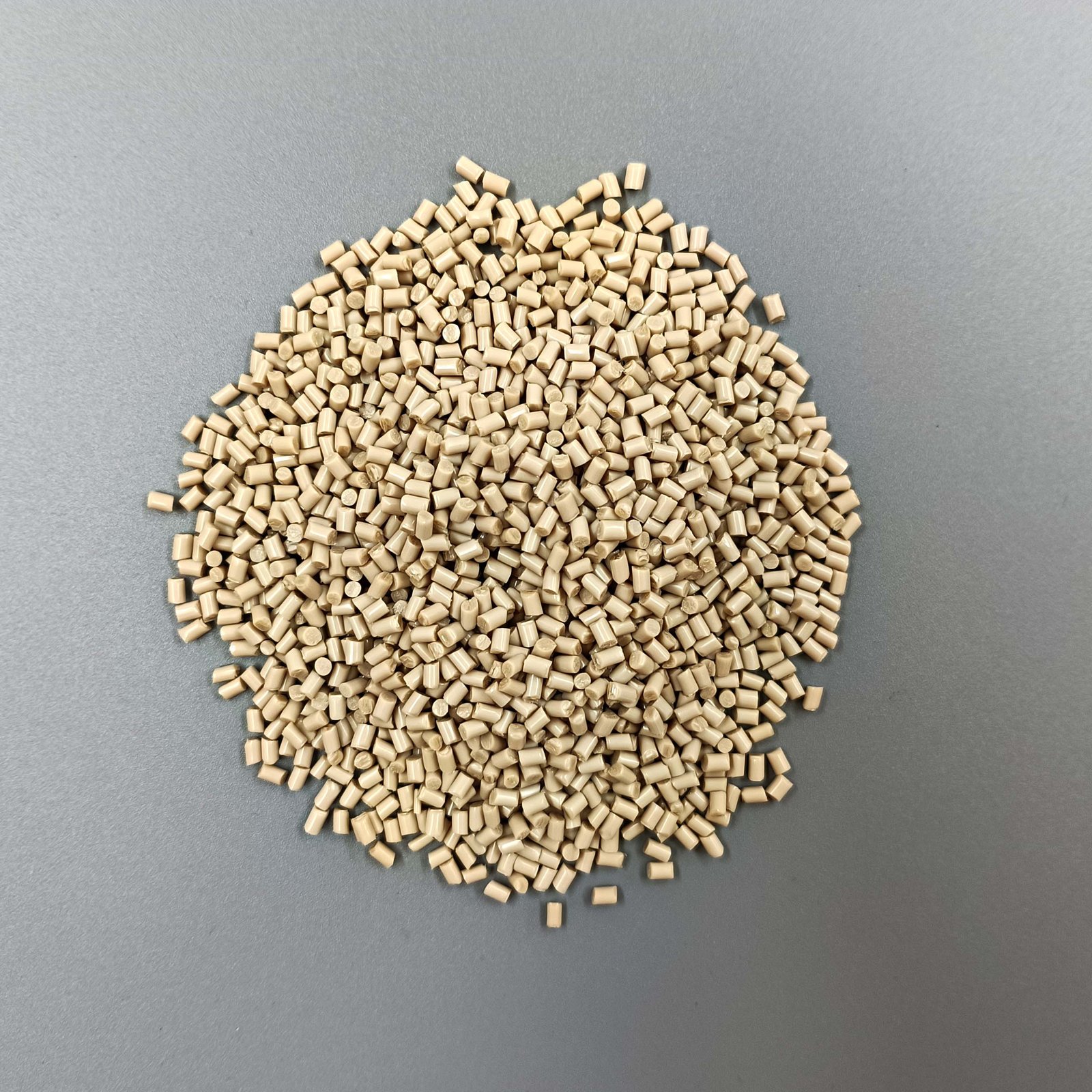

LUVOCOM® 3F PEEK CF 9676 BK is a carbon fiber-reinforced, flame-retardant grade of PEEK from Lehmann & Voss, Germany, part of its high-performance PEEK polymers portfolio.

It combines the high-temperature resistance and chemical stability of PEEK resin with the high strength and low deformation of carbon fiber reinforcement. A proprietary modification system achieves both flame retardancy and hydrolysis resistance.

This PEEK polymers are suitable for both mass injection molding and 3D printing of functional parts, offering an engineering plastic solution for connecting high-precision components with high reliability.

01 | Core Advantages

Carbon fiber reinforcement significantly improves the material's rigidity and fatigue resistance. With a tensile modulus of approximately 10 GPa, it maintains structural stability under high loads, making it an ideal choice for lightweight metal replacements.

・Excellent flame retardancy: The formula has passed UL94 V-0 testing, meeting the flame retardancy safety requirements for electrical equipment and automotive components.

・Excellent hydrolysis resistance: It maintains stable mechanical properties even after long-term exposure to high temperature, humidity, or steam, making it suitable for equipment operating in wet and hot environments.

・Strong chemical stability: It resists corrosion from a variety of acids, bases, fuels, and industrial solvents, making it suitable for corrosive environments such as the chemical and energy industries.

・Excellent dimensional and moisture absorption control: Low water absorption (0.1%) and minimal shrinkage (0.1–0.5%) ensure that parts maintain their precision during processing and long-term use.

・Sustained high-temperature resistance: It can withstand continuous use at 250°C and short-term exposure to 280°C. It also has a heat deflection temperature of 280°C, making it suitable for long-term heat load environments.

02 | LUVOCOM® 3F PEEK CF 9676 BK Data Sheet

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | 50 mm/minuut | ISO527 | 3.4 | % | |||

| Treksterkte | 50 mm/minuut | ISO527 | 145 | MPa | |||

| Trekmodulus | 1,0 mm/min | ISO527 | 10 | GPa | |||

| Charpy Un-notch-impact | ISO179 | 90 | kJ/m² | ||||

| Charpy Un-notch-impact | ISO179 | 90 | kJ/m² | ||||

| Charpy Notch-impact | ISO179 | 12 | kJ/m² | ||||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Operating temperature | Continuous 20000hr | IEC 60216 | 250 | ℃ | |||

| Operating temperature | Maximum Long-term 200hr | 280 | ℃ | ||||

| HDT | ISO75 | 280 | ℃ | ||||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Wateropname | 23℃ 24 uur | ISO62 | 0.1 | % | |||

| Krimp | DIN 16742 | 0.1~0.5 | % | ||||

| Dikte | ISO1183 | 1.34 | g/cm³ | ||||

| Smeltindex | 380℃ 10kg | ISO1133 | 16 | g/10min | |||

| Smeltindex | 380℃ 10kg | ISO1133 | 14 | cm³/10min | |||

| Elektrische eigenschappen | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Insulation Resistance | IEC 60167 | 109 | Ω.cm | ||||

| Oppervlakteweerstand | IEC 60093 | 1.09E2 | Ω | ||||

03 | Manufacturing Compatibility: A Dual-Platform Material from Injection Molding to 3D Printing

LUVOCOM® 3F PEEK CF 9676 BK is one of the few peek polymers that meets both injection molding requirements for mass production and high-temperature 3D printing.

Spuitgietproces

・It exhibits stable melting characteristics (MFR 16 g/10min) at 380°C, uniform flow, low shrinkage, and excellent dimensional repeatability after molding.

3D Printing Process

・The filament version optimizes interlayer bonding and thermal conductivity for the FFF process, effectively reducing warpage and internal stress, making the printed parts closer to injection molded parts in strength and appearance.

04 | Typical Application Areas

Aerospace and Aerospace Systems: Used in high-temperature connectors, electrical insulation frames, and structural reinforcements;

Automotive Powertrain Systems: Used in turbocharger housings, heat flow ducts, and thermal insulation brackets;

Medical and Semiconductor Equipment: Suitable for autoclaving or chemical solvent environments;

Industrial Machinery: Used in pump bodies, bearings, and seals, offering corrosion resistance and long service life.

05 | Industry Trends in Peek Polymers

As engineering plastics evolve toward "lightweighting + functional integration," the application boundaries of PEEK polymers are continuously expanding.

Carbon fiber-reinforced systems like LUVOCOM® 3F represent three future directions for engineering plastics:

・Multi-performance composites that combine structure and function;

・Sustainable formulations that support digital manufacturing (3D printing);

・Reliable structural materials that maintain long-term stability under extreme operating conditions.

These trends are driving material upgrades in the aviation, energy, and medical equipment sectors, and are also making collaboration between traders and manufacturers more technologically advanced.

06 | Frequently Asked Questions (FAQs)

Q1: Can this material withstand long-term contact with hot oil or coolant?

A: Yes. Its chemical resistance covers motor oil, gasoline, ethylene glycol, and aviation lubricants.

Q2: Is the performance of 3D-printed parts significantly different from injection-molded parts?

A: After optimizing the printing temperature (approximately 400°C), the strength of printed parts can reach 85-90% of that of injection-molded parts.

Q3: Are conductive or EMI-shielding versions available?

A: The LUVOCOM® series offers a variety of carbon fiber and conductive additive formulations, which can be customized based on the project.

07 | Recommended Materials in the Same Category (Chemical Resistance Recommendations)

| Fabrikant | Productmodel | Dikte | Treksterkte | Verlenging | Smelttemperatuur | Trekmodulus | Warmteafbuigingstemperatuur | Notched Izod Impact | Property Summary |

| Bada | PEEK 3111 GF 30 | 1.5 g/cm³ | 170 MPa | 2.50% | 343 ℃ | 11500 MPa | 328 ℃ | "Viscosity: High viscosity Flammability rating: V-0Notched impact: 10 kJ/m² Melting temperature: 343 °C" | |

| Bada | PEEK 3111 CF30 black | 1.40 g/cm³ | 260 MPa | 1.50% | 343 ℃ | 27000 MPa | 330 ℃ | 11 kJ/m² | "Viscosity: High viscosity Flammability rating: V-0 Notched impact: 11 kJ/m² Melting temperature: 343 °C" |

| Bada | PEEK 3111 GF30 uncoloured | 1.40 g/cm³ | 260 MPa | 1.50% | 370–390 ℃ | 27000 MPa | 330 ℃ | 11 kJ/m² | "Viscosity: High viscosity Flammability rating: V-0 Notched impact: 11 kJ/m²" |

08 | Why Choose Juyuan

As a professional supplier specializing in the international trade of peek polymers for 24 years, Juyuan provides customers with:

・Original import channels and technical documentation;

・Supports sample testing, long-term orders, and mixed batch shipments.

・Long-term stable supply and flexible packaging solutions;

・Injection molding and printing process parameter references are provided;

Juyuan is committed to providing customers with a reliable and transparent material supply chain, making the application of engineering plastics such as PEEK more efficient and competitive.

【Gerelateerde aanbevelingen】

InLube™ PEEKBGHF: Lubricated PEEK Polyether Ether Ketone Meer informatie>

PEEK 2287 LF: Low-Flow Reinforced PEEK Plastic for Precision Structural Meer informatie>

How to Choose the Right Plastic Raw Materials for Water Pipe Manufacturing Meer informatie>