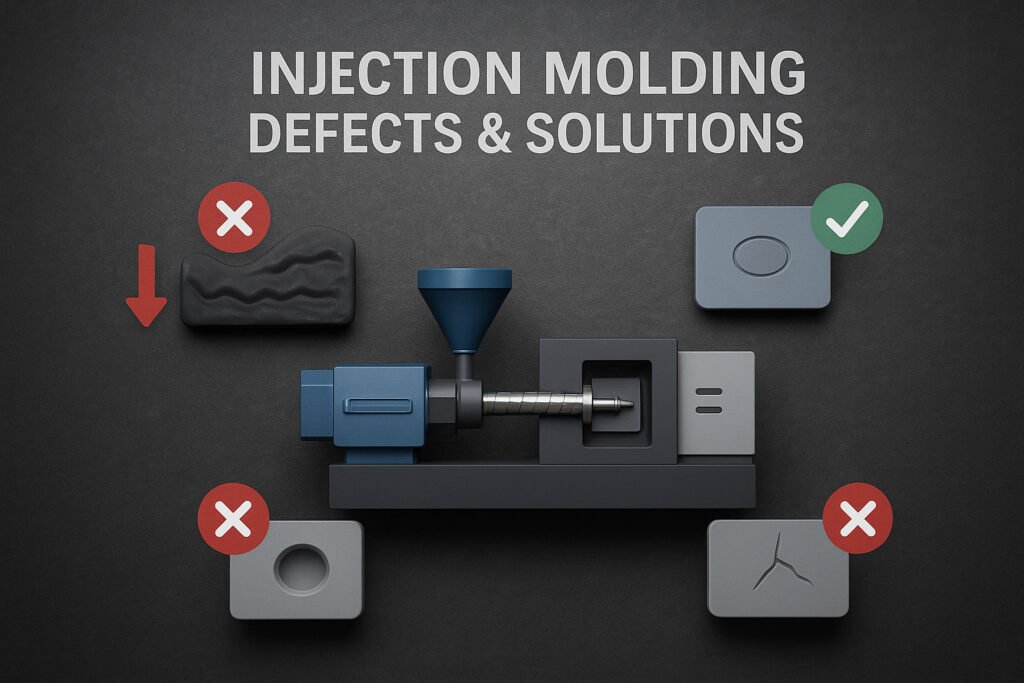

In industries ranging from automotive parts and medical devices to consumer electronics and food packaging, the stability of injection molded parts directly determines the performance of the end product.

However, during the production process, buyers and manufacturers often encounter various defects, leading to increased scrap rates, delivery delays, increased mold maintenance costs, and even reduced customer satisfaction.

This article, drawing on industry practices, analyzes common issues and provides actionable optimization measures.

I. Shrinkage and Shrinkage Sinks

Typical manifestations: Part size is too small, and sinking occurs in thick-walled areas.

Common scenarios: Automotive exteriors and electronic product casings.

Solution:

・Process Recommendations: The holding time is typically set to 2.5-3 times the filling time and monitored in real time using a cavity pressure sensor. The holding pressure can be controlled in stages, with high pressure in the early stages and gradually reduced in the later stages.

・Mold Design: Add cooling water channels to thick-walled areas to ensure temperature uniformity. For large parts, sequential valve gates can be used to reduce uneven shrinkage.

・Material Selection: For PP/PE, mineral-filled or glass fiber-reinforced grades can be selected, which can reduce shrinkage by over 30%.

II. Warpage

Typical manifestations: The part bends or twists, making assembly difficult.

Common applications: Thin-walled structural parts and long strips.

Solution:

・Process Recommendations: Reduce injection speed to minimize molecular orientation stress; the mold temperature difference should be controlled within ±3°C.

・Mold Design: Use CAE flow analysis to predict warpage trends and adjust gate layout accordingly.

・Material Selection: Using glass fiber-reinforced PA6/PA66 can effectively reduce warpage risk.

III. Bubbles and Voids

Typical manifestations: Pores appear inside or on the surface of the part, affecting strength.

Common applications: Transparent parts and medical device components.

Solution:

・Process Recommendations: For hygroscopic materials such as PC and PPSU, it is recommended to dry them in a vacuum oven at 120°C for 4–6 hours, keeping the moisture content below 0.02%. Use a moderate injection speed to avoid air entrainment.

・Mold Design: A vent groove depth of 0.02–0.05 mm is generally recommended. Vacuum exhaust devices can be added to thick-walled areas.

・Detection Methods: An online moisture detector can be used to ensure stable drying of the raw materials.

IV. Scorch Marks

Typical Symptoms: Black spots or scorch marks appear on the surface of the product.

Common Scenario: Slender runners and thin-walled products.

Solution:

・Process Recommendations: Reduce screw back pressure to prevent melt stagnation. Reduce the injection speed by 10–20% to reduce air compression.

・Mold Design: Provide vent holes or vent pins at the end of the melt. Add auxiliary gates in areas of high flow resistance.

V. Silver Striation and Flow Marks

Typical Symptoms: Silvery-white streaks or ripples appear on the surface.

Common Applications: Transparent parts and exterior parts.

Solution:

・Material Management: Strictly control drying temperature and time. For PC, drying at 110–120°C for ≥ 3 hours is recommended.

・Process Recommendations: Keep material temperature as close to the upper limit of the recommended value as possible; use staged injection speed control, with rapid filling in the early stages and slow pressurization in the later stages.

・Mold Design: Avoid gates in areas where appearance requirements are high.

VI. Weld Marks

Typical Manifestation: Linear marks appear where the melt converges.

Common Applications: Automotive interior parts and medical housings.

Solution:

・Process Recommendations: Increase mold temperature by 5–10°C; slightly increase injection speed to ensure rapid melt convergence.

・Mold Design: Adjust gate position so that the melt converges in a non-critical area. For high-demand parts, add an auxiliary heating system.

VII. Difficult Demolding

Typical Manifestation: Part sticking or deformation during ejection.

Common Applications: Deep-cavity parts and threaded components.

Solution:

・Mold Design: Draft angle recommended: ≥ 1°; transparent PC parts can be increased to 2–3°. The mold surface can be chrome-plated or nitrided to reduce friction.

・Process Recommendations: Allow sufficient cooling before ejection; use a staged ejection system to reduce stress.

VIII. Buyer's Implications

Injection molding defects are not only a technical challenge but also have a commercial impact:

・Reducing defect rates = saving material and labor costs

・Reducing downtime for mold adjustments = improving delivery efficiency

・Optimizing materials and processes = improving customer satisfaction

For international buyers, choosing a supplier that understands both materials and processes offers greater long-term value than simply considering price.

IX. Juyuan's Advantages

As an international plastic raw material supplier, Juyuan not only offers engineering plastics such as PEEK, PPSU, PA, PC, and POM, but also provides:

・Material and application matching recommendations (medical, automotive, electronics, packaging)

・Mold and process optimization support (CAE analysis, process parameter guidance)

・Global supply chain assurance (overseas warehousing, fast delivery)

・Compliance and certification support (FDA, ISO, UL Yellow Card)

We help customers reduce defects, improve efficiency, and make their products more competitive in the global market.

X. Conclusion

Injection molding is a complex system engineering process, and deviations at any stage can lead to defects. Through scientific process optimization, reasonable mold design, and the right material selection, manufacturers can not only reduce defect rates but also ensure supply chain stability.

If you are looking for a trustworthy plastic raw material partner and would like to receive technical support at the process level, please contact Juyuan. We will provide you with a one-stop solution to help your products stand out in the international market.