PRODUCTEN

Inleiding tot mLLDPE PF1315AZ voor flexibele verpakkingen

Productconstructie

MLLDPE PF1315AZ Inleiding

mLLDPE PF1315AZ is een additiefvrije metallocene lineaire lagedichtheidspolyethyleen (mLLDPE) basishars met uitstekende mechanische eigenschappen en weerstand tegen omgevingsspanningsscheuren (ESCR). De lagedichtheidseigenschappen zorgen ervoor dat het materiaal uitstekende flexibiliteit vertoont terwijl het een hoge treksterkte en perforatieweerstand behoudt, en stabiele fysieke prestaties behoudt binnen een breed verwerkingsvenster.

1、MLLDPE Materiaaleigenschap

Metallocene LLDPE PF1315AZ is geschikt voor verwerking zoals spuitgieten, extrusiecoating en laminering. De uitstekende warmteafdichtbaarheid en verwerkingsaanpassing geven het een aanzienlijk voordeel in flexibele verpakkingsfilms, samengestelde verpakkingsmaterialen en meerlaagse co-geëxtrudeerde structuren. Bovendien maken de hoge smeltstroomsnelheid (MFR) en uitstekende verwerkingsstabiliteit van mLLDPE PF1315AZ het ideaal voor Masterbatch Carrier Resin en extrusiecoatingprocessen, wat zorgt voor uitstekende dikte-uniformiteit en kwaliteitsconsistentie.

2. Toepassingen van MLLDPE-pellets

Op basis van de uitstekende algehele prestaties wordt mLLDPE PF1315AZ veel gebruikt in de kunststofverwerking, met name voor de productie van flexibele verpakkingen met hoge prestaties, warmtelaslagen en meerlaagse composietfolies. Het biedt een betrouwbare prestatiegarantie en verwerkingsgemak voor het eindproduct.

3、MLLDPE-harsparameters

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Oever | Hardheid D | ISO 868 | 46 | ||||

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | Opbrengst | ISO527 | 22 | % | |||

| Verlenging | Pauze | ISO527 | 600 | % | |||

| Buigzaam | Modulus 23°C | ISO178 | 244 | MPa | |||

| Izod | Kerf Impact -20°C Type A | ISO180 | 71 | kJ/m² | |||

| Treksterkte | Module | ISO527 | 217 | MPa | |||

| Treksterkte | Sterkte Opbrengst 23°C | ISO527 | 9 | MPa | |||

| Treksterkte | Sterkte pauze | ISO527 | GEEN ONDERBREKING | MPa | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | 23°C | ISO1183 | 914 | kg/m³ | |||

| Milieu | Spanningsscheurweerstand | INTERNE METHODE | 175 | uur | |||

| Smelten | Index 190°C 2,16 kg | ISO1133 | 15 | g/10min | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Gem. | Warmte van fusie | ASTM D3418 | 104 | J/g | |||

| Kristallisatie | Temperatuur | INTERNE METHODE | 100~84 | °C | |||

| Smeltend | Temperatuur DSC 10°C/min 2e Verwarming | ISO11357 | 96~114 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 10N | ISO306 | 90 | °C | |||

Klik hier om TDS voor mLLDPE PF1315AZ te downloaden

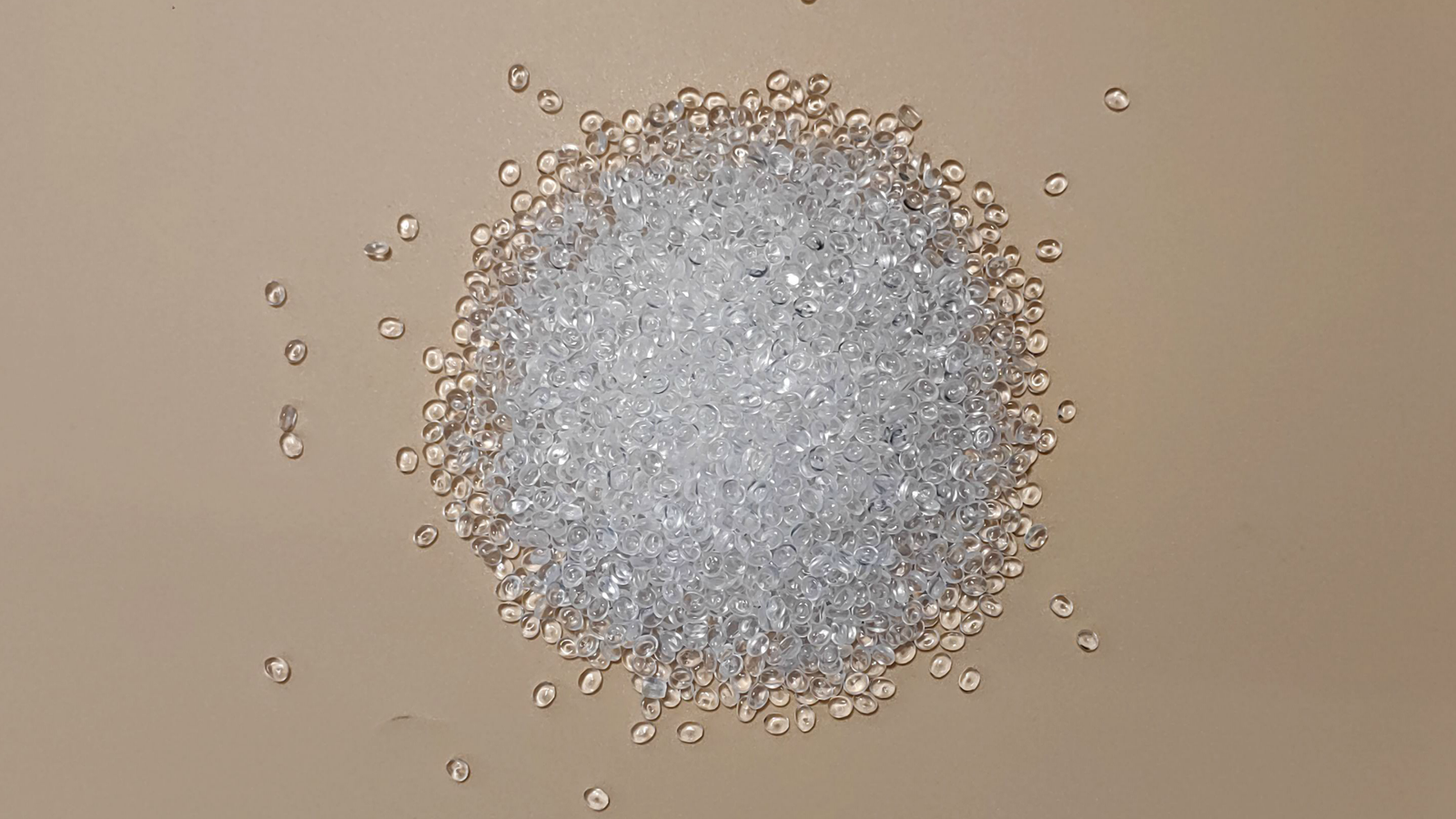

4、Metallocene LLDPE-korreldisplay

【Gerelateerde aanbevelingen】

mlLDPE 8784MK: Hoogwaardige mlLDPE voor barrièrefolies en vloeistofverpakkingen Meer informatie>

mlLDPE HP1018BM: Hoog-impactbestendig mlLDPE voor verpakkings- en folietoepassingen Meer informatie>

mlLDPE D174: Hoogwaardige filmkwaliteit copolymeer voor extrusietoepassingen Meer informatie>