PRODUCTEN

Producten

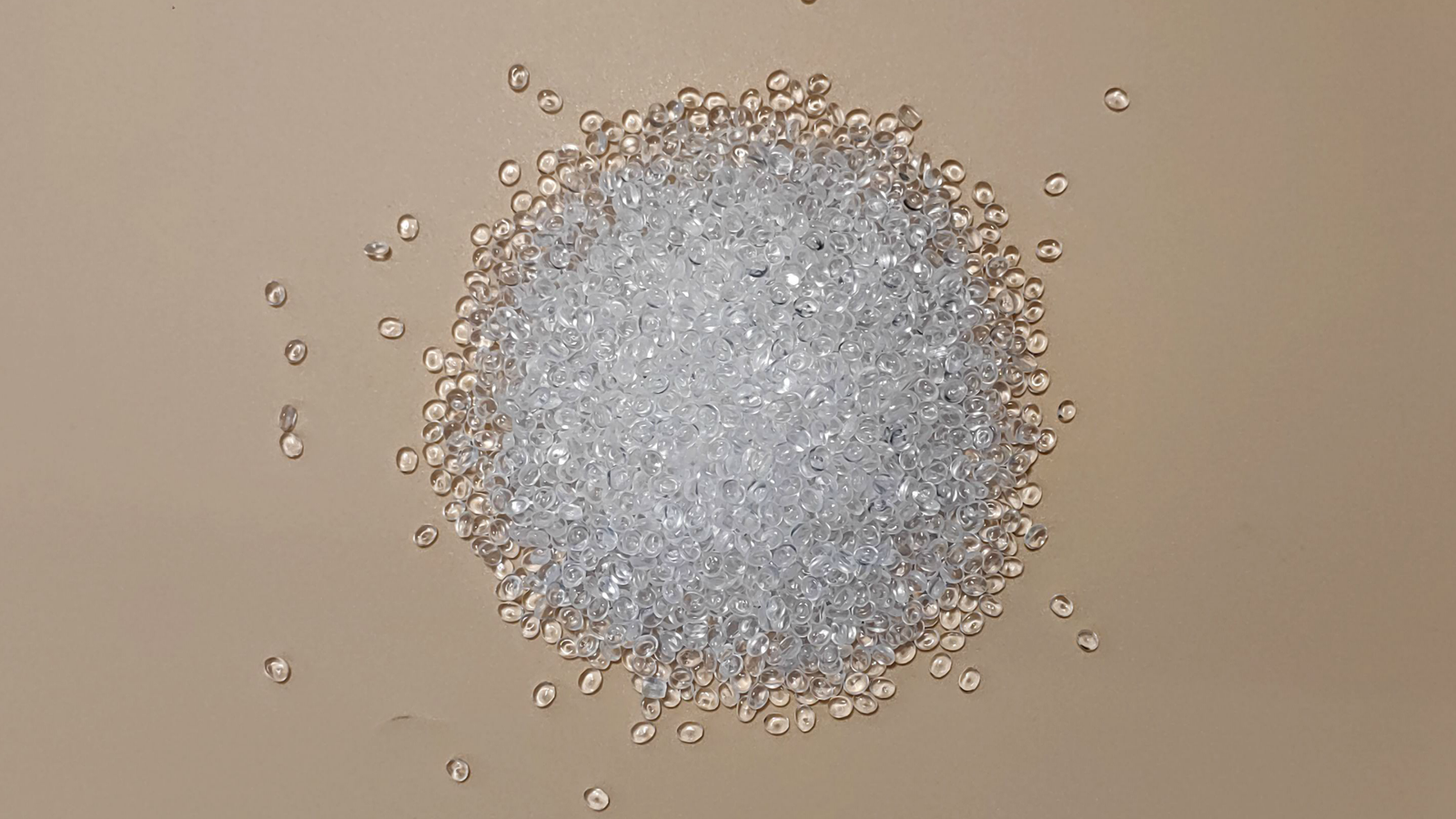

High-Performance mLLDPE 1327MD for Flexible Packaging

Productconstructie

mLLDPE 1327MD plastic pellets are a high-performance linear low-density polyethylene (mLLDPE) copolymer with a natural appearance, designed for blow molding processes. Its material properties include film grade and blow molding grade and meet food contact standards. The addition of opening agents and a six-carbon copolymer enhances its processing properties and mechanical strength.

The material is characterized by high modulus and high toughness, making it excellent for film applications. It provides good flexibility, tear resistance, and puncture resistance. Its excellent barrier properties make it widely used in food and industrial packaging, including box lining bags, barrier food packaging, bread bags, sealed packaging, upright bags, garbage bags, zipper bags, and shrink films.

In addition, mLLDPE 1327MD adds opening agents, heat stabilizers, forming additives and slip enhancers to optimize processing performance, improve the surface smoothness of the film, and enhance the ease of use of the film, making it an ideal choice for high-quality packaging materials.

Looking for high-quality [product/material]? Reach out now to discuss your needs with our experts!

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Elmendorf | Tear Strength Flow | ASTM D1922 | 190 | G | |||

| Elmendorf | Tear Strength xFlow | ASTM D1922 | 450 | G | |||

| Verlenging | Stroomonderbreking | ASTM D882 | 560 | % | |||

| Verlenging | xFlow-pauze | ASTM D882 | 620 | % | |||

| Vallen | Weight Impact Strength | ASTM D1709 | 140 | G | |||

| Puncture | Resistance | INTERNE METHODE | 38 | N | |||

| Puncture | Resistance | INTERNE METHODE | 1.7 | J | |||

| Secant | Modulus 1% Flow | ASTM D882 | 310 | MPa | |||

| Secant | Modulus 1% xFlow | ASTM D882 | 330 | MPa | |||

| Treksterkte | Strength Flow Yield | ASTM D882 | 13 | MPa | |||

| Treksterkte | Strength xFlow Yield | ASTM D882 | 14 | MPa | |||

| Treksterkte | Krachtstroompauze | ASTM D882 | 47 | MPa | |||

| Treksterkte | Sterkte xFlow Break | ASTM D882 | 39 | MPa | |||

| Optische prestaties | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Glans | 45° | ASTM D2457 | 25 | ||||

| Nevel | ASTM D1003 | 26 | % | ||||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | ASTM D1505 | 0.927 | g/cm³ | ||||

| Smelten | Index 190°C 2,16 kg | ASTM D1238 | 1.3 | g/10min | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Smeltend | Temperature Peak | INTERNE METHODE | 123 | °C | |||

| Vicat | Verzachtingstemperatuur | ASTM D1525 | 116 | °C | |||