PRODUCTEN

ABS-materiaaloverzicht | High-Flow ABS PA-737 voor de automobielindustrie

Productconstructie

Wat is ABS-materiaal?

ABS PA-737 is een hoogwaardig ABS-materiaal dat speciaal is ontwikkeld voor spuitgieten en dat uitstekend presteert in uiteenlopende industriële scenario's.

1. Eigenschappen van ABS-materiaal

Verschijning: ABS PA-737-materiaal heeft een glad oppervlak en een mooi uiterlijk, wat voldoet aan de uiterlijke eisen van hoogwaardige producten.

Vloeibaarheid: Goede vloeibaarheid, kan snel en gelijkmatig worden gevuld in complexe mallen, verbetert de gietefficiëntie en nauwkeurigheid.

Verwerkingsprestaties: hoge verwerkingsstabiliteit, goede thermische stabiliteit, eenvoudig te bereiken hoge precisie vormgeving.

Verwerkingssnelheid: Door de snelle verwerkingseigenschappen, geschikte smeltviscositeit en kristallisatie-eigenschappen kan de productiecyclus worden verkort.

Vlamvertragend: tot de HB-vlamvertragingsnorm kan de brandsnelheid onder specifieke testomstandigheden worden geregeld en zal de vuurbron na het verwijderen vanzelf doven om de veiligheid te garanderen.

2. Toepassing van ABS-materiaal

Automobielindustrie: ABS-materiaal Wordt gebruikt voor de decoratie van het interieur en exterieur van auto's en voor sommige functionele onderdelen, waarbij rekening wordt gehouden met schoonheid, duurzaamheid en veiligheid.

Fabricage van kantoorapparatuur: Geschikt voor de behuizing van kantoorapparatuur, verbetert het uiterlijk en de betrouwbaarheid.

Huishoudelijke apparatenindustrie: Wij produceren behuizingen voor huishoudelijke apparaten om esthetiek, veiligheid en levensduur te verbeteren.

Productie van dunwandige producten: Dankzij de goede vloeibaarheid en snelle verwerkingseigenschappen kunnen wij voldoen aan de vraag van de verpakkings-, elektronica- en andere industrieën naar dunwandige producten.

3. Het effect van additieven

Voeg smeermiddel en lossingsmiddel toe om de verwerkingsprestaties te verbeteren. Smeermiddelen verminderen de wrijving tussen moleculaire ketens, verbeteren de vloeibaarheid en minimaliseren slijtage van de apparatuur. Ondertussen vormt het lossingsmiddel een isolatiefilm tussen het product en de mal, wat een soepele lossing mogelijk maakt, de productie-efficiëntie verhoogt en zorgt voor een betere productkwaliteit.

4、ABS-materiaalgegevensblad

| Ontvlambaarheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Vlam | Waardering Alle kleuren 1,5 mm | UL94 | HB | ||||

| Vlam | Waardering Alle kleuren 3,0 mm | UL94 | HB | ||||

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Rockwell | Hardheid R (schaal) | ASTM D785 | 103 | ||||

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Charpy | Kerfslag 23°C | ISO179 | 25 | kJ/m² | |||

| Charpy | Kerfimpact -30°C | ISO179 | 11 | kJ/m² | |||

| Verlenging | 6 mm/minuut | ASTM D638 | 22 | % | |||

| Verlenging | 50 mm/minuut | ISO527 | 20 | % | |||

| Buigzaam | Sterkte 2,8 mm/min | ASTM D790 | 590 | kg/cm² | |||

| Buigzaam | Sterkte 2,0 mm/min | ISO178 | 60 | MPa | |||

| Buigzaam | Modulus 2,8 mm/min | ASTM D790 | 20000 | kg/cm² | |||

| Buigzaam | Modulus 2,0 mm/min | ISO178 | 1.9 | GPa | |||

| Izod | Kerf Impact 23°C 6,4mm | ASTM D256 | 18 | kg-cm/cm | |||

| Izod | Kerf Impact 23°C 3,2mm | ASTM D256 | 25 | kg-cm/cm | |||

| Izod | Kerfslag 23°C | ISO180 | 24 | kJ/m² | |||

| Izod | Kerf Impact -30°C | ISO180 | 10 | kJ/m² | |||

| Treksterkte | Sterkte opbrengst 6mm/min | ASTM D638 | 360 | kg/cm² | |||

| Treksterkte | Sterkte Opbrengst 50 mm/min | ISO527 | 38 | MPa | |||

| Treksterkte | Sterktebreuk 50mm/min | ISO527 | 32 | MPa | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | 23°C | ASTM D792 | 1.04 | g/cm³ | |||

| Dikte | 23°C | ISO1183 | 1.04 | g/cm³ | |||

| Smelten | Index 200°C 5kg | ASTM D1238 | 2.6 | g/10min | |||

| Smelten | Index 220°C 10kg | ISO1133 | 31 | cm³/10min | |||

| Krimp | ISO294 | 0.4~0.7 | % | ||||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CLE | ISO11359 | 9E-5 | cm/cm/°C | ||||

| HDT | Gegloeid 1,8 MPa | ASTM D648 | 93 | °C | |||

| HDT | Niet-gegloeid 1,8 MPa | ASTM D648 | 83 | °C | |||

| HDT | Niet-gegloeid 1,8 MPa | ISO75 | 81 | °C | |||

| HDT | Gegloeid 1,8 MPa | ISO75 | 96 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 10N | ASTM D1525 | 101 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 10N | ISO306 | 103 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 50N | ISO306 | 96 | °C | |||

| UL | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Boog | Weerstand | ASTM D495 | 7 | BV | |||

| Vergelijkend | Trackingindex | EN 60112 | 1 | BV | |||

| HAI | ALLE 1,5 mm | UL746A | 0 | BV | |||

| HAI | ALLE 3,0 mm | UL746A | 0 | BV | |||

| HVTR | UL746A | 0 | BV | ||||

| HWI | ALLE 1,5 mm | UL746A | 4 | BV | |||

| HWI | ALLE 3,0 mm | UL746A | 4 | BV | |||

| RTI | Elektrisch ALLE 1,5 mm | UL 746B | 60 | °C | |||

| RTI | Elektrisch ALLE 3,0 mm | UL 746B | 60 | °C | |||

| RTI | Imp ALLE 1,5 mm | UL 746B | 60 | °C | |||

| RTI | Imp ALLE 3,0 mm | UL 746B | 60 | °C | |||

| RTI | Str ALLE 1,5 mm | UL 746B | 60 | °C | |||

| RTI | Str ALLE 3,0 mm | UL 746B | 60 | °C | |||

| UL | Vlamwaarde ALLES 1,5 mm | UL94 | HB | ||||

| UL | Vlamclassificatie ALLES 3,0 mm | UL94 | HB | ||||

Klik hier om TDS voor ABS PA-737 te downloaden

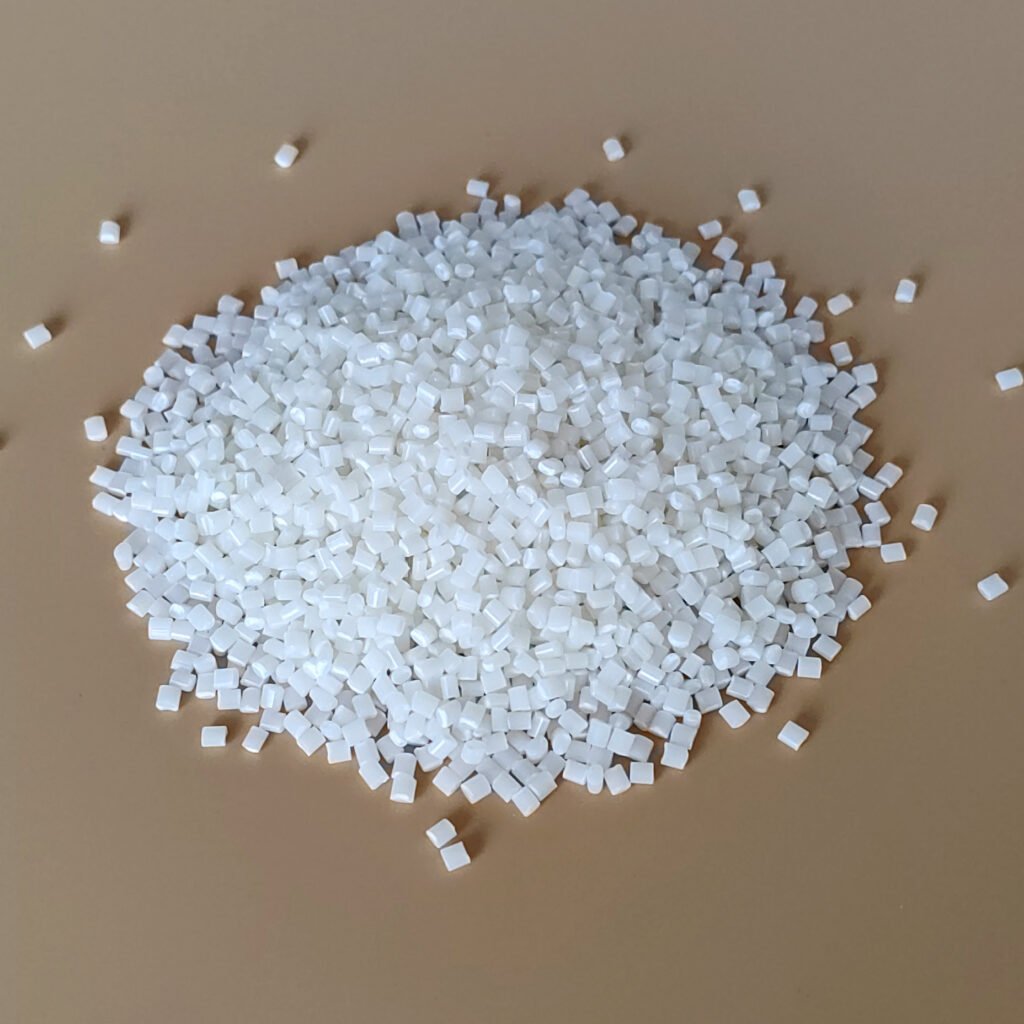

5、ABS-materiaaldisplay

6. Conclusie

ABS PA-737 biedt uitstekende prestaties en wordt veel gebruikt in de automobielindustrie, kantoorapparatuur, huishoudelijke apparaten en andere sectoren, waardoor het een ideaal materiaal is voor spuitgieten. Met de ontwikkeling van technologie wordt verwacht dat het aantal toepassingsmogelijkheden zal toenemen.

【Gerelateerde aanbevelingen】

Welk materiaal is ABS? Meer informatie>

ABS D-90-pellets:Hoogglans, stijf spuitgieten van ABS voor elektronica Meer informatie>

ABS PA-747H:Duurzaam, chemisch bestendig ABS-kunststof voor huishoudelijke apparaten Meer informatie>