Introduction

In the physical property table of plastic raw materials, Flame retardancy Rating (flame Retardant Rating) is one of the indicators that purchasers pay the most attention to. It directly determines the safety, compliance and market access of materials in applications. Whether it is electronic appliances, automotive parts, or medical devices, flame retardant performance is an important basis for material selection and certification.

This article will take you through a comprehensive understanding of the meaning of flame retardant grades, international standards, the impact of thickness on test results, and key application points in different industries.

01 | Core Concept: What is flame retardant grade?

The flame retardancy grade is an evaluation given after a series of standardized combustion tests assess the performance of plastic materials when they come into contact with fire sources. It does not mean that the material is completely non-combustible, but rather reflects the material's ability to slow down the spread of flames and self-extinguish after being removed from the fire source. This indicator is of vital importance in industries such as electrical, electronic, automotive, home appliances, and construction.

02 | The source of flame retardant grades: International standard system

The flame retardant grade is not randomly marked by enterprises, but is evaluated based on internationally accepted standards:

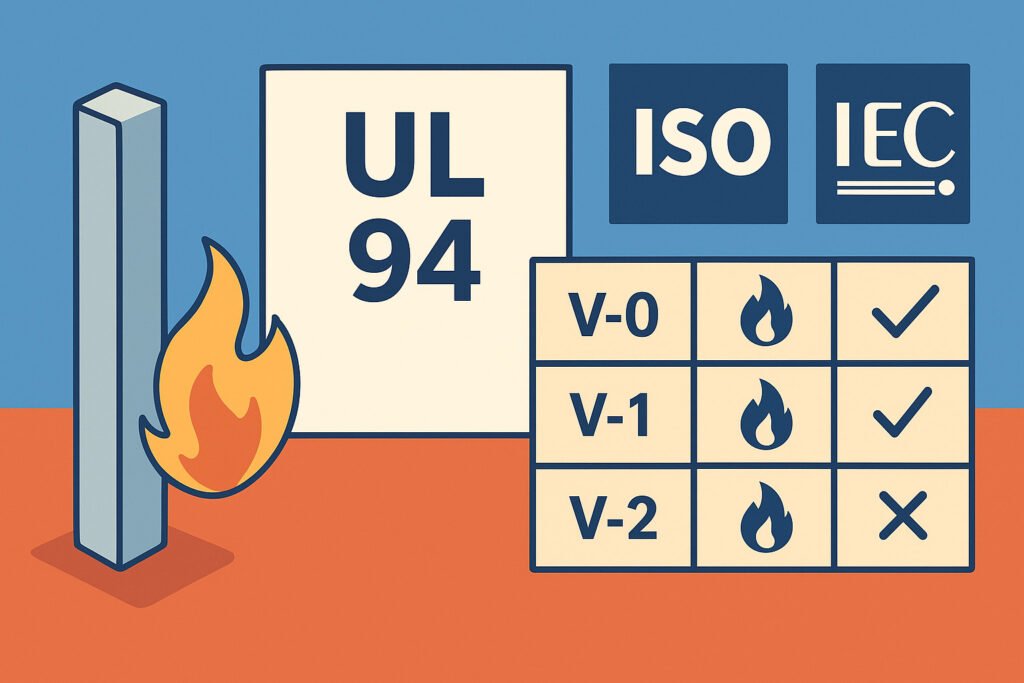

UL (Underwriters Laboratories, an American underwriters laboratory)

・The most commonly used standard is UL94, which is widely applied in electronic appliances, automobiles and medical equipment.

ISO (International Organization for Standardization, International Organization for Standardization)

・For instance, ISO 9772 is often used for testing the combustion performance of foam plastics.

IEC (International Electrotechnical Commission, International Electrotechnical Commission)

・Safety standards representing the field of electrical and electronic engineering, such as the IEC 60695 series.

A simple understanding:

UL → Certified by the United States, it is the most commonly used plastic for electrical appliances worldwide.

ISO → An internationally recognized standard, facilitating cross-border trade.

IEC → Focus on electrical and electronic safety standards.

What does the test number represent?

In the physical property table, you often come across numbers such as UL94, ISO 9772, and IEC 60695

・UL94 → UL Flame Retardant Standard No. 94

・ISO 9772 → ISO No. 9772 standard, mainly tests the horizontal burning of foam plastics

・IEC 60695 → IEC 60695 series standards, used for fire hazard testing in electrical and electronic equipment

These numbers are the standard numbers, indicating the specific methods followed by the tests.

03 | Common Classifications of Flame Retardant Grades (Taking UL94 as an Example)

In the plastic industry, the most widely used flame retardant standard is UL 94 of Underwriters Laboratories in the United States. Most of the common flame retardant grades (HB, V-0, V-1, V-2, etc.) on the physical property table are based on this standard.

UL 94 HB (Horizontal Burning)

・Test method: Place the spline horizontally and ignite one end.

・Grade requirements

Thickness 3-13mm: Burning speed < 40mm/min

Thickness < 3mm: Burning speed < 75mm/min

・Interpretation: Minimum flame retardant grade, the material is flammable, but the burning speed is limited.

UL 94 V (Vertical burning)

・Test method: Place the spline vertically and ignite the lower end.

・Classification requirements:

V-0: Each combustion ≤10 seconds; Total combustion ≤50 seconds; No flammable droplets.

V-1: Each burning ≤30 seconds; Total combustion ≤250 seconds; Dripping is allowed, but the cotton pad must not be ignited.

V-2: The same as V-1, but it allows droplets to ignite the cotton pad.

・Comparison and summary

| Rating | Single Burning Time | Total Burning Time | Dripping Behavior | Vlamvertraging |

| V-0 | ≤10 s | ≤50 s | Nee | Best |

| V-1 | ≤30 s | ≤250 s | Nee | Uitstekend |

| V-2 | ≤30 s | ≤250 s | Ja | Goed |

UL 94 5VA / 5VB

・Test method: More rigorous board combustion test, repeatedly igniting with a 500W flame.

・Grade requirements

5VB: The board can be burned through, but there should be no flammable droplets.

5VA: The board cannot be burned through and it is the highest flame retardant grade.

The Importance of thickness

The flame retardant grade is directly related to the thickness of the spline. For example, a material can reach V-0 at 1.6mm, but it may only reach V-2 at 0.8mm. Therefore, it is usually marked as "UL 94 V-0 @ 1.6mm" on the physical property table. If the wall thickness of the terminal product is less than this value, the flame retardant grade cannot be guaranteed.

04 | The influence of thickness on Flame Retardancy grade

The flame retardant grade must be understood in combination with the thickness of the material.

The flame retardant results of the same material may vary greatly at different thicknesses:

| Materiaal | 3.0 mm | 1.5 mm | 0.8 mm |

|---|---|---|---|

| PC (Polycarbonate) | V-0 | V-0 | V-2 |

| ABS (Flame-Retardant Grade) | V-0 | V-1 | HB |

| PA66 (Flame-Retardant Grade) | V-0 | V-0 | V-1 |

| PP (General Grade) | HB | HB | HB |

📌 When engineers select materials, they must confirm whether the actual wall thickness of the parts is within the test thickness range; otherwise, the expected flame retardant grade may not be achieved.

05 | Examples of Common Flame-Retardant Plastics

Common flame-retardant modified materials

・After flame retardant modification, buikspieren, PC, PC/ABS alloy, PA66, PA6, PBT, PP, PPO, etc. are commonly classified as UL 94 V-0.

Natural flame-retardant materials (no need to add flame retardants)

・PVC

・PVDF (Polyvinylidene fluoride)

・PEEK (Polyetheretherketone)

・PPS (Polyphenylene sulfide)

These materials inherently contain flame-retardant elements (such as chlorine, fluorine, and aromatic rings) in their structure, which can naturally achieve a relatively high flame-retardant grade.

06 | Application Scenarios of Flame Retardant Grades

HB → Household items, daily plastic parts

V-2 → Industrial components, some automotive interiors

V-1 → Office equipment enclosures, electrical components

V-0 → Electrical enclosures, medical equipment, automotive structural components

5VA/5VB → High-risk electrical equipment, automotive engine compartment components

07 | Environmental Protection and Regulatory Trends

With the tightening of global environmental regulations, Halogen-Free Flame (Retardant) is becoming mainstream.

Under the requirements of EU regulations such as RoHS and REACH, an increasing number of purchasers are paying attention to whether materials meet the requirements of green environmental protection.

08 | Tips from Juyuan

As an international plastic raw material trader, Juyuan suggests that purchasers pay close attention to:

・Whether the flame retardant grade meets the certification requirements of the target market;

・Whether the flame retardancy of the material can be balanced with its mechanical properties and processing performance;

・Whether the supply chain is stable and can ensure compliance in the long term.

Juyuan has many years of international trade experience and provides customers with a stable supply of plastic raw material pellets, as well as selection support for different application scenarios.

Conclusie

Flame retardant grade is not only a set of symbols (HB, V-2, V-0), but also a key indicator for product safety and market access.

Understanding the differences among UL, ISO and IEC, and paying attention to the relationship between thickness and flame retardant performance can help purchasers make more professional and safer material selection decisions.

Juyuan will continue to provide reliable plastic raw material pellets for global customers, helping various industries achieve safer and more sustainable material applications.