PRODUCTEN

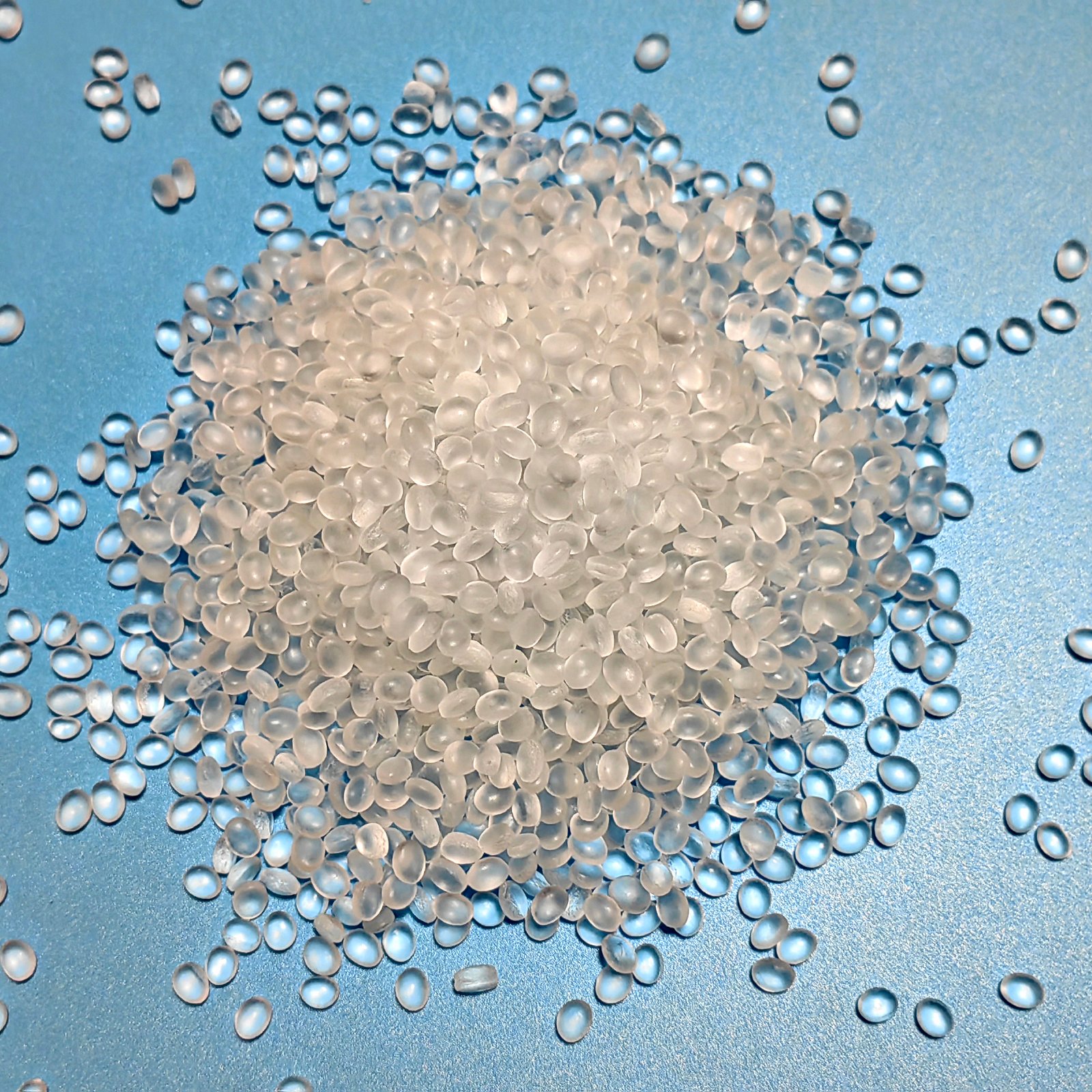

ExxonMobil POE 0203 Overzicht | Hoge helderheid POE-kunststof

Productconstructie

What is POE Plastic

As multilayer films and functional modified materials become increasingly high-performance, ExxonMobil POE 0203, as a POE plastic material with high clarity, flexibility and good processability, is rapidly becoming a new favorite in packaging, home furnishing, modified resins and other fields. Its unique low-temperature sealing properties and hot adhesive performance enable it to improve structural performance and product aesthetics while also bringing more freedom to the manufacturing end.

01 | Material properties: Precise control in flexible structures

POE plastic 0203 is a vinyl-based metallocene-catalyzed copolymer with the following core performance advantages:

・High clarity and excellent appearance performance: Suitable for composite film structures that require visual transparency, such as OPP films and barrier film layers.

・Excellent flexibility and puncture resistance: While maintaining a soft feel, it has high toughness and is suitable for replacing traditional EVA materials for packaging scenarios that are susceptible to extrusion and impact.

・Low temperature resistance: It can maintain sealing adhesion under low temperature conditions, suitable for cold chain packaging, frozen food edge sealing and other scenarios.

・Low density advantage (0.9~0.904 g/cm³): Reduce material usage while meeting performance requirements, which is beneficial to cost control and lightweight design.

・Moderate melt index (2.5~3.5 g/10min): Gives it excellent extrusion fluidity, suitable for a variety of film blowing or co-extrusion processes.

02 | Processing adaptability: Flexible blending and molding process full coverage

POE 0203 plastic shows extremely high process adaptability:

・It has good compatibility with polyolefin materials such as PP, and can be used as a blending modifier to improve the impact toughness and flexibility of PP materials, and is widely used in halogen-free flame retardant modified material systems.

・It supports a variety of processes such as extrusion molding, composite co-extrusion, and cast molding, and is particularly suitable for use as a sealing layer and thermal bonding layer in a multi-layer film structure.

・In soft foam applications, with its low melting point and good resilience, it can be used in conjunction with EPE or POE foam systems, and is suitable for protective packaging, household goods, or insole cores.

03 | Application scenario expansion: more than just "packaging", more high value-added solutions

POE 0203 plastic is not just "a soft material", it is being used by more and more companies in the following subdivided scenarios:

・Barrier film and laminating film system: as a heat-sealing layer with smooth structure and high transparency, it helps to create high-performance cold-seal packaging or high-gas barrier packaging.

・Household products and daily chemical containers: with high surface finish and soft feel, it is very suitable for sealing caps, soft packaging materials and other products that require hand feel and flexibility.

・PP modification: as a variety with strong compatibility with PP among the poe plastic types, it can effectively improve the low-temperature toughness and peeling performance of the masterbatch.

・Film composite molding: applied to the middle layer or inner layer of the multi-layer structure, it can effectively buffer stress transfer and improve overall durability.

04 | Overview of typical physical properties

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid |

| Dikte | INTERNE METHODE | 0.9~0.904 | g/cm³ | |

| Smeltindex | 190°C 2,16kg | INTERNE METHODE | 2.5~3.5 | g/10min |

05 | Why choose POE 0203?

・Want to improve the softness and sealing performance of film products?

・Need to create a reliable hot-adhesive structure in low temperature environment?

・Looking for a highly transparent and flexible modification solution in the PP system?

POE 0203 is a solution for the above needs. It is not only a modified raw material, but also a comprehensive functional material that gives the product "ductility, toughness, and visual".

06 | Why choose us instead of just focusing on the brand?

When choosing high-performance materials such as POE 0203, many customers often only focus on the "brand", but what really determines the delivery efficiency and service quality is often the supplier you cooperate with.

As an experienced virgin plastic granule trader, we not only provide genuine ExxonMobil POE 0203 materials, but also have the following differentiated advantages:

・Fast spot response: always have inventory, reduce waiting cycles, and support urgent order delivery.

・Full technical consultation support: assist in selection, application formula suggestions, processing adaptation guidance, far better than ordinary distribution.

・More flexible prices: We have a multi-channel procurement system to strive for more competitive procurement costs for you.

・Stable supply chain: Control the entire process from procurement to logistics to ensure long-term supply security.

・Support customized modification and matching: Can assist in matching PP, PE and other blending formulas to improve product performance and market competitiveness.

The brand determines the quality of the material itself, and we determine whether you can put this material into use efficiently, safely and at low cost.

📩 Contact us now to get samples, technical information and exclusive quotes. We not only sell raw materials, but also help your products win the market.

【Gerelateerde aanbevelingen】

POE 8203: Flexibel en helder polyolefine-elastomeer voor extrusie- en blaasfolietoepassingen Meer informatie>

POE 8150: Functioneel polyolefine-elastomeer voor structurele versteviging Meer informatie>

POE 8100: Vernetbaar polyolefine-elastomeer voor toepassingen met hoge vulling en flexibele kabels Meer informatie>