PRODUCTEN

Edgetek™ PF-20GF/000 Polysulfone Material for Injection Molding

Productconstructie

What is Edgetek™ PF-20GF/000

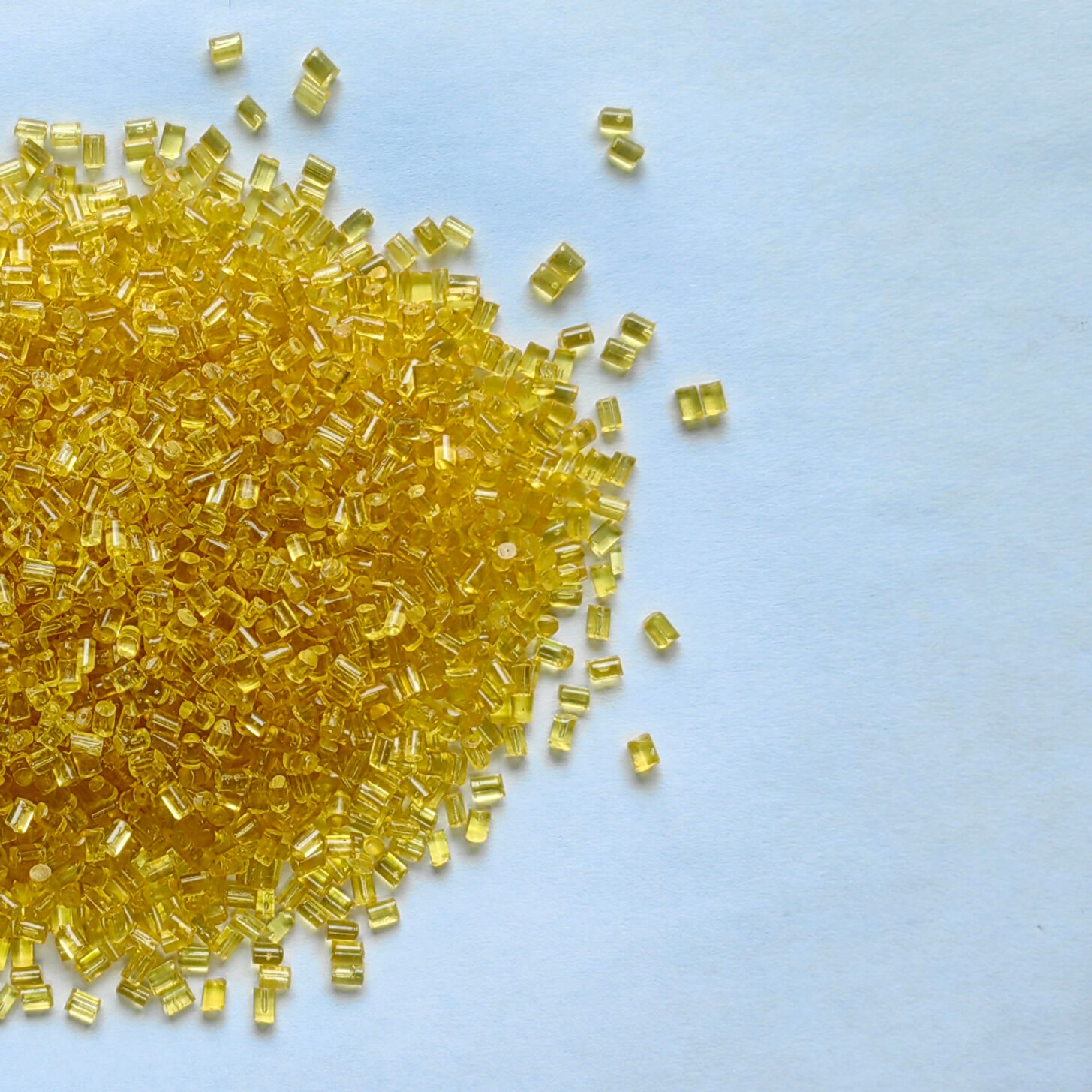

PSU PF-20GF/000 is a glass-fiber-reinforced, flame-retardant polysulfone material developed by PolyOne. It comes in granular form and is designed for injection molding. This material demonstrates stable mechanical strength and dimensional accuracy under high temperatures, prolonged loads, and complex application scenarios, making it a reliable material choice for engineering components and electronic products.

01 | Material Core Advantages

Reinforced Structure: 20% glass fiber content ensures excellent rigidity and deformation resistance under high stress.

Flame Retardancy: Meets V-0 rating and self-extinguishes even in high-temperature environments, enhancing the safety of electronic and industrial equipment.

Outstanding Thermal Stability: A high heat deflection temperature combined with a low coefficient of linear expansion effectively ensures component precision under high temperatures or cyclic thermal stress.

Excellent Moisture Resistance: Low water absorption ensures stable performance in humid environments, preventing dimensional expansion or mechanical property degradation.

Comprehensive Mechanical Properties: Outstanding tensile, flexural, and compressive strength meet the strength and durability requirements of various industrial applications.

02 | Typical Applications

Edgetek™ PF-20GF/000's combination of properties makes it suitable for a variety of industries:

・Electronic and electrical equipment: High-temperature switches, connector housings, and precision electronic components

・Mechanical components: Gears, pump bodies, valves, and other components requiring both rigidity and heat resistance

・Automotive: Electronic modules surrounding engines and small structural components

・Medical equipment: Instrument housings and structural components requiring indirect chemical and heat resistance

03 | Processing and Process Recommendations

This polysulfone material is suitable for injection molding, especially for complex molds and precision structural parts. Its low shrinkage and high rigidity ensure accurate part dimensions after molding, reducing secondary processing and improving production efficiency. For industrial parts requiring long-term high reliability, this material offers stable processing performance.

04 | Polysulfone Material PSU PF-20GF/000 Data Sheet

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | Break 5.1mm/min | ASTM D638 | 3.0 | % | |||

| Schuifsterkte | ASTM D732 | 62.7 | MPa | ||||

| Druksterkte | ASTM D695 | 138 | MPa | ||||

| Buigsterkte | ASTM D790 | 152 | MPa | ||||

| Buigmodulus | ASTM D790 | 5520 | MPa | ||||

| Izod Notch-impact | 23℃ 6,40mm | ASTM D256 | 69 | J/m | |||

| Treksterkte | Break 5.1mm/min | ASTM D638 | 103 | MPa | |||

| Trekmodulus | 5.1mm/min | ASTM D638 | 5520 | MPa | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| HDT | 0.45MPa 3.20mm | ASTM D648 | 185 | ℃ | |||

| HDT | 1.80MPa 3.20mm | ASTM D648 | 179 | ℃ | |||

| CLE | xFlow | ASTM D696 | 2.9E-5 | cm/cm/°C | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Wateropname | 24 uur | ASTM D570 | 0.20 | % | |||

| Wateropname | Verzadiging | ASTM D570 | 0.60 | % | |||

| Krimp | xFlow | ASTM D955 | 0.30 | % | |||

| Dikte | ASTM D792 | 1.38 | g/cm³ | ||||

| Elektrische eigenschappen | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Volumeweerstand | ASTM D257 | 1E16 | Ω.cm | ||||

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Rockwell-hardheid | M(Schaal) | ASTM D785 | 92 | ||||

| Ontvlambaarheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Vlamclassificatie | UL94 | V-0 | |||||

05 | Industry Innovation and Competitive Advantages

Innovative Material Design: The combination of glass fiber reinforcement and a flame-retardant formula achieves long-term stability under high temperatures and loads, distinguishing it from traditional polysulfone materials.

Leading Comprehensive Performance: In the electronics, automotive, and mechanical industries, polysulfone material provides a solution that simultaneously meets heat resistance, flame retardancy, and mechanical properties.

Extended Service Life: Scientific design ensures long-term component deformation and performance degradation, reducing maintenance costs.

06 | Customer Experience Feedback

・Users in the Electronics Industry: High part molding precision and satisfactory high-temperature resistance.

・Automotive Parts Manufacturers: Strong chemical resistance and long-term stability.

・Mechanical Equipment Customers: High rigidity ensures part strength and service life.

Overall, customers generally believe that Edgetek™ PF-20GF/000 performs stably and reliably in high-end applications, making it particularly suitable for projects with stringent requirements for part strength and heat resistance.

07 | Similar recommendations

| Fabrikant | Product Code | Dikte | Treksterkte | Verlenging | Krimp | Trekmodulus | Heat Deflection Temp | Rockwell-hardheid | Notched Izod Impact | Buigmodulus | Coefficient of Thermal Expansion | Buigsterkte |

| PolyOne | PF-20GF | 1.38 g/cm³ | 103 MPa | 3% | 0.35% | 5520 MPa | 185 ℃ | 92 | 69 J/m | 5520 MPa | 2.9E-5 cm/cm/℃ | 152 MPa |

| PolyOne | NY-33GF/000 | 1.39 g/cm³ | 186 MPa | 4% | 0.30% | 10300 MPa | 218 ℃ | 121 | 187 J/m | 9700 MPa | 2.88E-5 cm/cm/℃ | 290 MPa |

| PolyOne | PF-40GF/000 | 1.56 g/cm³ | 145 MPa | 2% | 0.10% | 11700 MPa | 193 ℃ | 92 | 117 J/m | 11000 MPa | 2.16E-5 cm/cm/℃ | 183 MPa |

| PolyOne | NY-43GF/000 | 1.46 g/cm³ | 179 MPa | 3.50% | 0.10% | 10300 MPa | 216 ℃ | 120 | 160 J/m | 9700 MPa | 2.34E-5 cm/cm/℃ | 241 MPa |

| PolyOne | PF-40CF/000 | 1.4 g/cm³ | 179 MPa | 3% | 0.05% | 6890 MPa | 185 ℃ | — | 74.7 J/m | 18600 MPa | 1.8E-5 cm/cm/℃ | 255 MPa |

| PolyOne | PF-10GF/000 | 1.3 g/cm³ | 82.7 MPa | 2% | 0.40% | 5170 MPa | 177 ℃ | — | 53.4 J/m | 5170 MPa | — | 103 MPa |

| PolyOne | PF-20CF/000 | 1.31 g/cm³ | 128 MPa | 3% | 0.10% | 11000 MPa | 179 ℃ | — | 85.4 J/m | 11000 MPa | — | 155 MPa |

| PolyOne | PF-30CF/000 | 1.36 g/cm³ | 159 MPa | 2.50% | 0.10% | 14500 MPa | 185 ℃ | — | 69.4 J/m | 14500 MPa | — | 228 MPa |

08 | Frequently Asked Questions (FAQ)

Question: Can PSU PF-20GF/000 be used in high-temperature electronic components?

Answer: Yes, its high heat distortion temperature and low linear expansion characteristics ensure the dimensional stability of parts at high temperatures.

Question: Will materials absorb water in a humid environment?

Answer: The material has a low water absorption rate and can maintain its physical properties and mechanical strength.

Question: What processing methods are recommended?

Answer: Injection molding is the best choice and is suitable for applications that require high precision and complex structures.

09 | Juyuan's Supply Advantages

As a professional international supplier of polysulfone materials, Juyuan provides:

・Continuous and stable supply, resolving customer procurement issues

・Professional material selection advice, helping customers quickly match their application needs

・Flexible international logistics, shortening lead times and reducing procurement costs

・Customized packaging and batch solutions to meet varying purchase sizes

・Technical support services, covering processing techniques and application problem-solving

Summary

PSU PF-20GF/000, with its glass fiber reinforcement, flame retardancy, thermal stability, and comprehensive mechanical properties, is an ideal material for industrial parts and electronic equipment manufacturing. Juyuan provides reliable global supply and professional technical support, ensuring customers can fully realize the performance potential of polysulfone materials.

【Gerelateerde aanbevelingen】

LATILUB PSU 95-25GR CE/10 vs 95-15T: Self-Lubricating PSU Meer informatie>

LASULF G/20 | Stable & Low Smoke Polysulfone Plastic Meer informatie>

Plastics for Power Tools: Selection & Procurement Guide | Juyuan Meer informatie>